The field of plastic product manufacturing is very busy nowadays. Most companies that have manufactured products require the services of an established plastic product manufacturer to produce plastic products for their business. These products have to be carefully designed and built to a precise specification to meet the needs of the end user. For most entrepreneurs, finding a reliable plastic product manufacturing company to develop plastic products is a major concern.

If you are searching for an experienced and professional product manufacturing company, then don’t forget to check following five traits that a plastic product manufacturer should possess:

Work Force – Qualified and skilled product designers and engineers can work with the clients to help develop or improve components. These experienced professionals can troubleshoot and give advice to help design and build a better component and eventually a polished product. Always opt for a company that has highly skilled and experienced workforce.

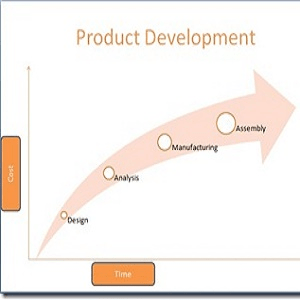

Manufacturing Techniques – The product manufacturing company should be able to fulfill the expectations not only in the existing scenario but also in the coming future. As per development requirements, plastic product manufacturing companies around the globe use a variety of manufacturing techniques. A plastic product manufacturer who is aware about different manufacturing techniques gives peace of mind that they will be able to handle the project in the near future also.

Manufacturing Capability – A product manufacturing company should be to operate round-the-clock. If your product is successful, then rush job will occur from time to time. The ability to work round-the-clock will be a much-needed characteristic at some point in the design and development process. Manufacturing companies operating only one shift may not be able to handle larger or unanticipated orders.

Customer Service – Not a surprise, customer service is equally important as the workforce, manufacturing techniques, and manufacturing capability. Keep a keen watch on some tiny yet decisive factors like – do they answer the call quickly, are they able to provide satisfactory solutions, are they interested in your project or not, are they nice and friendly, and many more aspects that are similar. If they are not, it is recommended to find a new plastic product manufacturer who can answer all these questions.

Facilities – Does the product development company have more than one manufacturing plant to produce their goods? The actual concern here is that a fire or industrial accident could shut the plant down. Such problems can adversely affect the production rate, as the manufacturing plant would be shut down for a time. Another deciding factor is the location of the company that you plan to hire. For example, if your company is located halfway around the world, then the shipping of developed products may consume a lot of time and must be planned for accordingly.

These may be general characteristics, but play a vital role in custom product manufacturing. Almost every plastic product manufacturer offers manufacturing services, but only a few mature companies seriously care about these characteristics and features to offer ultimate plastic product manufacturing to end users.

For more information, please contact GID Company. GID is a plastic product manufacturer located in California. They excel in every aspect of plastic product manufacturing to cut down production time, especially, when there is a strict deadline for a product.