The field of plastic product manufacturing has marked a remarkable growth in the last few decades. It involves all forms of plastic production, including extrusion, injection molding, cast molding, and calendaring. Manufacturing plastic products with the help of a professional plastic product manufacturer is profitable and offers a sustainable cutting edge in the business competition. Not only, the products manufactured from plastic are light in weight and cost-effective in producing, but are also durable, safer, flexible, and are aesthetic in appearance.

We are GID, a Plastic Product Development Company located in California, and since our inception, we have witnessed a promising growth of plastic products in different spheres of activity with an ever-increasing per capita consumption. With uninterrupted advancements and developments in manufacturing technology, processing machineries, and cost-effective manufacturing, plastic is the fast replacing the typical materials in different segments.

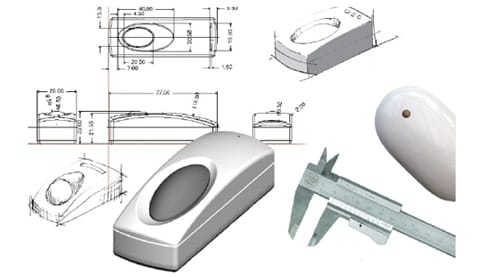

However, unless you have a thorough understanding, a plastic product manufacturing is not at all an easygoing process. It involves many calculative manufacturing phases, and a miscalculation can lead to an unimaginable tragedy. According to the product development experts at GID, all the hazards can be minimized with the help of product prototyping. A product prototype development is done to help make the modifications and fixes on a product before the final product is mass-produced.

GID states top advantages of prototyping in the field of plastic product manufacturing, and they are as follows:

1. Allows a Business Owner to Preview the Final Product

As we know, a prototype is nothing but a fully functional, working model of a product to be developed; it includes all the features and functionality to a larger or smaller scale. Prototype development in the plastic manufacturing industry is extremely important as it offers a general picture of products that are still in the beta stage. It allows you to see, touch, test, and discover what works and what doesn’t. A prototype allows entrepreneurs, financiers, and end-users to visualize the product quickly and communicate what insights they have for the final product. You can conclude whether the prototype meets the requirements of potential users and then make modifications before the final product is ready.

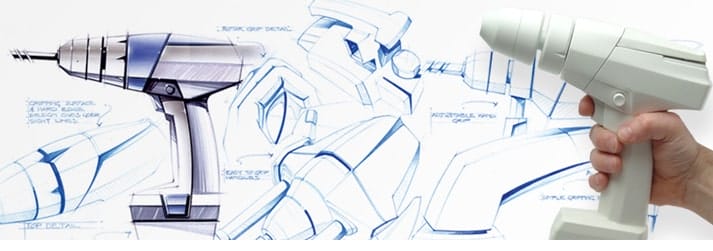

2. Controlled Manufacturing Cost and Time

A product prototyping allows a business owner to test his/her concept of product and discover any flaws. Business owners have the opportunity to correct these imperfections, or emerge with solutions for improving the product. This step reduces the risk of your product failing; thereby, drastically reducing manufacturing cost and time.

3. Generates Curiosity among the End-users and Financiers

When an entrepreneur develops a prototype, investors and end-users get the opportunity to explore it and give suggestions. Consumers can test the features and functionality of the plastic product and give their valuable feedback. In this way, entrepreneurs have a chance to improve their product and shape it as per customer’s requirements.

Apart from the above-mentioned advantages, a product prototype development in the plastic product manufacturing allows an entrepreneur to easily adjust a product design and fix some features of the products. Prototyping together with the injection molding can really benefit the plastic industry in countless ways.

To know more about plastic product manufacturing at reasonable rates, feel free to contact GID at www.gidcompany.com. GID is a plastic product manufacturer who creates a variety of rapid plastic prototypes and plastic products for different segments of industry. To talk to product manufacturing experts or to share your concept, call them at 714-323-1052.