When it comes to realizing a new product idea into the physical form, many entrepreneur inventors underestimate various costs that are involved. These inventors underrate not only the product development costs but most of the other vital costs as well.

Underestimating the costs is especially true for medical device products. Inventors should never make the mistake of misjudging various costs, as it can hinder their success. Rather, they should learn and know all the different types of costs involved in bringing a new medical device product into the market.

Remember, the total cost to take a new product from just a mere concept to a mass-manufactured product widely varies. If it is a complex product, the total costs may reach to a hefty figure. Anyway, let us look at some of the most common costs that are involved when it comes to realizing a new medical device product into a physical form and taking it to the market.

Product Design Costs

The conceived product idea needs to be elaborated, and product design helps in this regard. Rough, hand-drawn sketches are carefully drawn into proper drawings by the professionals. These drawings are then elucidated even more using computer applications, like CATIA, SOLIDWORKS, etc.

While creating the drawings or 3D models using a computer application, many changes are also made and tested in order to achieve a definitive and feasible product design. Making professional drawings and computer-generated 3D models requires experience and skills, and it costs a reasonable amount of money. The computer application itself, by the way, will cost a substantial amount of money.

Product Prototyping Costs

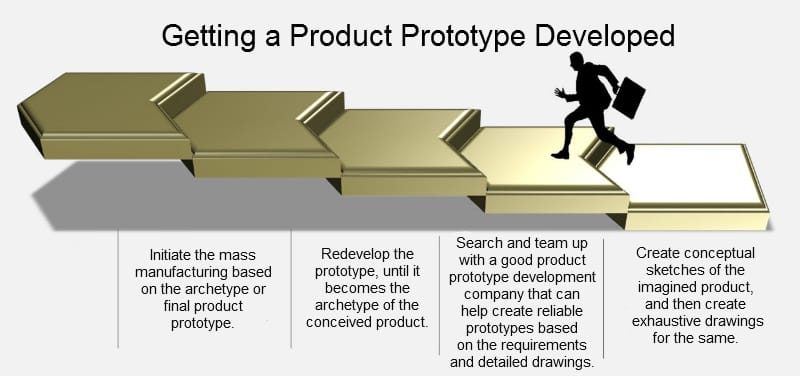

Every new product idea needs a prototype. Based on the definitive product design, a product prototype can be made. A product prototype gives the clear understanding of how the conceived product will physically look, feel and function. At the same time, a product prototype helps test the conceived product, eliminate any defects, and enhance certain functions.

Product prototype development is a complex task as it involves creating near perfect examples of the final product. It is arduous and intellectually challenging job. It will cost a substantial amount to develop definitive product prototypes.

Product Development Costs

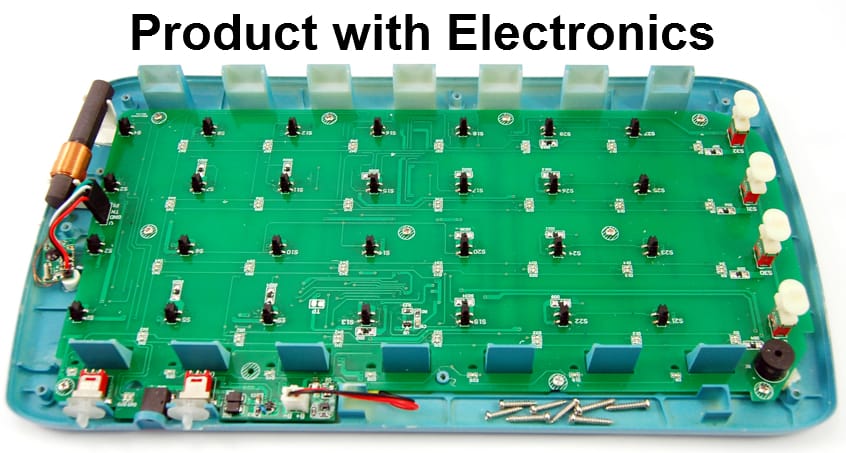

Based on the product prototype, the final product is developed. Since it is a medical device product, the product development costs can be broken down into (normally) three groups: the mechanical, the electronic, and the plastic.

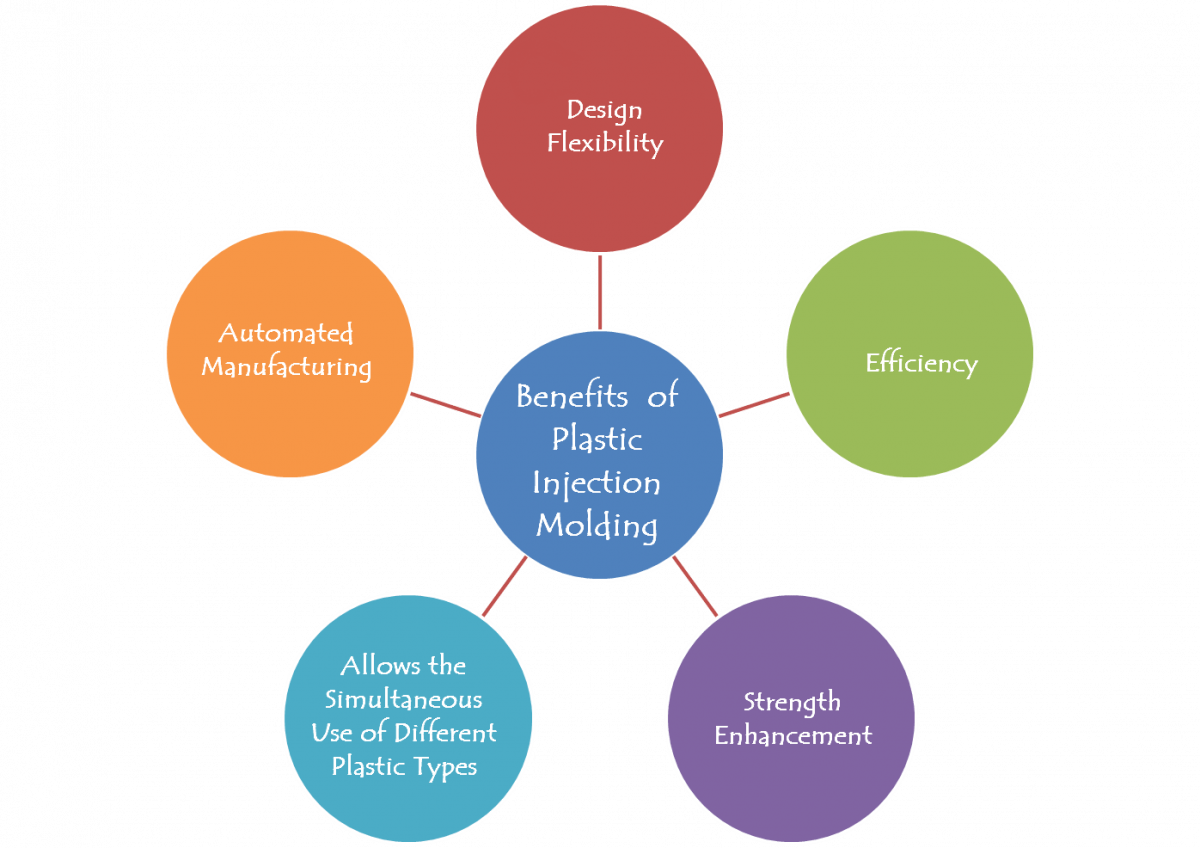

While the mechanical and electronic do all the magic, the plastic is responsible for holding the product together. Sometimes, instead of plastic, other materials may be used, but plastic is the most common, versatile, and economical material of choice.

Normally, the mechanical and electronic will be the most difficult and expensive to develop, and they will share a big proportion of the product development costs. The plastic parts or components will, comparatively, cost less to develop.

Copyright, Licensing & Certification Costs

While the normal copyright and licensing costs may not be exorbitant, the fees that inventors have to pay, if they hire professionals, are something worth considering.

For novice inventors, the process of acquiring the copyright and other licenses may seem overwhelming. At the same time, in order to protect the invention, acquiring the copyright and licenses is essential. For that reason, inventors may need to hire professionals who would help obtain the necessary copyright and licenses. These professionals will charge fees that are worth considering.

For medical device products, inventors need to obtain certain certifications from the US Food and Drug Administration (FDA). Acquiring these certifications will also cost some money.

Production Setup Costs

Inventors need to set up production facilities in order to mass manufacture the conceived product. Establishing a production facility is no easy feat, and it requires a considerable amount of capital.

Since it is a medical device product, hybrid production facility, which can mass manufacture and assemble mechanical, electronic, and plastic components, needs to be set up. Further, because it is a medical device product, the facility also needs to have a sterile environment. Forming such a facility will cost a massive amount of money.

The inventors, of course, have the option to partner with existing manufacturers, but that will also cost – not as much as establishing own facility, but a significant, nevertheless.

Well, these are just some of the common costs involved in materializing a new medical device product into a physical form and taking it to the market. Other costs such as branding, packaging, logistics, marketing, and so on are also involved.

If you are an inventor and need help in realizing a new medical device product and taking it to the market, then GID Development Corporation can help. A product development company in California, GID Development Corporation specializes in new product design, product prototyping, product development, plastic product manufacturing, and other product fulfillment services.

Whether it is medical device product development, electromechanical product development, sports product development, or generic or special-purpose product development, GID Development Corporation will surely “GET IT DONE!”

Want to learn more about the professional product development company in California, GID Development Company? Just visit https://www.gidcompany.com/.

A FREE 15-minute telephonic consultation is available! Just call Jim Grimes at 714-323-1052 between 8:00 AM to 5:00 PM PST.