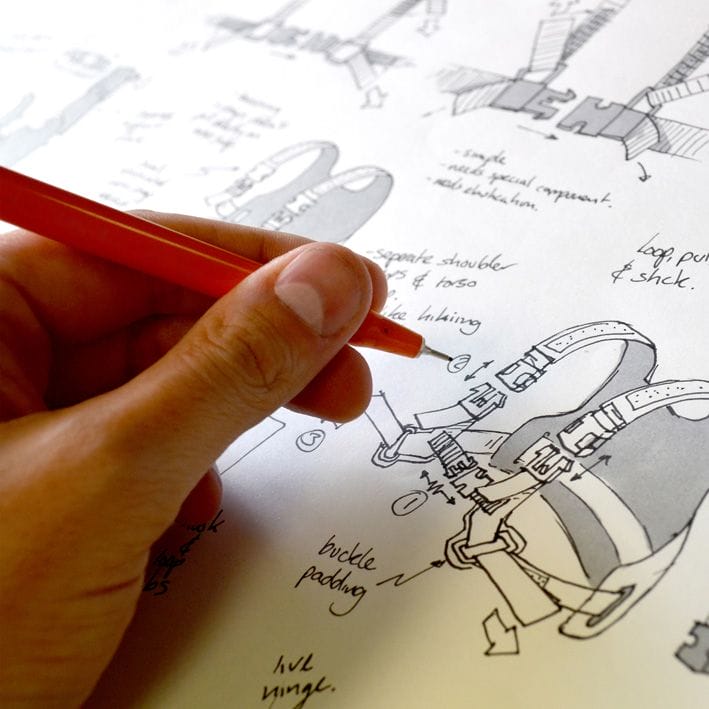

Conceived a brilliant idea for a groundbreaking new product? That is great! So now what? Well, as a prudent inventor, what you first need to do is build a prototype of your conceived product. No matter how simple and obvious your product concept sounds, the hard fact is that, realizing a new product is a very complicated task. Developing prototypes for your concept, however, can ease a lot of pain.

Prototype development plays a vital role in the new product development. Not only do prototypes give you a clearer picture of how your conceived product will look, feel, and function like, but they also help you attract the stakeholders as well as better the final product. With our years of experience in the field product development, we advise every inventor not to overlook the importance of building product prototypes. Product prototypes are the foundations of a new product. Here are some important guidelines to follow when developing product prototypes.

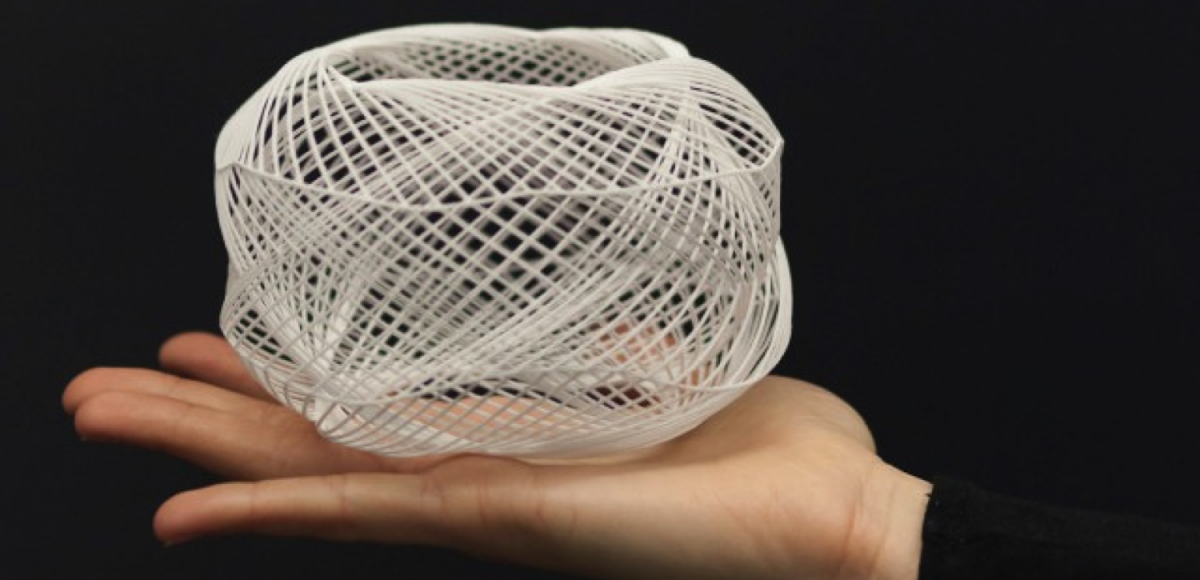

- Scale: One of the cardinal drawbacks when designing your concept in a computer application, like CATIA or SOLIDWORKS, is the lack of scale. A small 1-inch component or part of the conceived product can look big on the computer screen, but in the real-world, it is just a 1-inch component or part. To overcome this issue, what you need to do is 3D print the components as often as you can, especially for the small parts. 3D printing is not too expensive these days; you can either buy your own 3D printer or outsource your requirements to someone specializing in 3D printing. By 3D printing small components to judge the scale, you can avoid a lot of complications later on.

- Make a lot of prototypes: Don’t just create a single prototype; develop five or ten or as many as you can afford. When your product design is near its perfection, it is best to build several product prototypes. When assembling prototypes, try to do so with your hands. When you build the prototypes with your hands, you will know how they come together. Take notes of how each part fits and how many times you need to make the adjustments. If you can videotape yourself assembling the prototype, then by all means, do so. You can later re-watch the videos and figure out what is going wrong.

- Let someone else assemble the prototype for you: Ask your friend, family member or someone you know to assemble your prototype. Watch them closely. See how they interact with your prototype, and ensure that you give minimum instruction to them. That way, you will be able to easily and quickly identify all the pain points regarding the assembly of your prototype. It will certainly be frustrating to watch someone assemble your prototype, but believe it, this is a great way to gather knowledge about your prototype.

- Team up with a product prototype development company: When building your product prototype, you will, at some point, wish that you had a professional helping hand. After all, product prototype development is not a piece of cake! This is where a professional product prototype development company comes into play. Such a product prototype development company has skilled mechanical, electrical and all sorts of engineers who have years of experience in product prototyping. Not to forget, a prototype development company also has all the necessary tools and resources that help in product prototyping. Partnering with a product prototype development company is definitely not a bad idea. The company can point out where you are going wrong with your prototype, assist you overcome various problems, and can even help you build product prototypes from scratch.

Developing product prototypes is never a waste of time, efforts or resources. Prototypes help further your conceived product idea to reality. As an inventor, never overlook the importance of product prototype development. Just remember, developing prototypes is one of those important keys that lead to a successful outcome of your conceived product.

If you need help with new product prototype development, then partner with GID Development Corporation today. A leading product prototype development company in California, USA, GID Development Corporation provides product design, rapid product prototyping, product development and other product fulfillment services. Utilizing contemporary technologies, like the 3DEXPERIENCE Platform from Dassault Systèmes, which includes 3DVIA, CATIA V6, SOLIDWORKS, BIOVIA, and other CAD / CAM / CAE computer applications, and 3D printing processes, experienced engineers at GID Development Corporation can create accurate product prototypes, swiftly and economically.

Whether it is creating prototypes for electromechanical products, sports products, medical device products, embedded software products, or any novel products, GID Development Corporation, an expert product prototyping company in California, will “GET IT DONE!” Learn more about GID Development Corporation.

Have any queries regarding product prototype development? Or perhaps 3D printing? Just call Jim Grimes at 714-323-1052 between 8:00 AM to 5:00 PM PST, for a FREE 15-minute telephonic conference.