Are you looking to develop a new prototype model for an electronic product? Do you seek quality assistance and expert prototype development for electronic products? If you have a great idea for electronic product development then you can approach the best electronic product development company in California, GID Company. Well, if you have done the market research, defined the product features, and have everything set up on your end regarding the product you need to develop. Then the next step will be to develop a prototype model for the electronic product before the actual development takes place.

Developing a prototype model of the product is crucial as it will help you to get a clear idea of how your product will look, feel, and function. Based on the prototype model, it will be easy to enhance and improve the actual product. Not only will it be possible for you to test and validate the product but also you can get an insight into the runtime errors and defects. Most entrepreneurs will definitely build a prototype model before introducing the real product to potential customers.

Product Prototype Development For Electronic Products

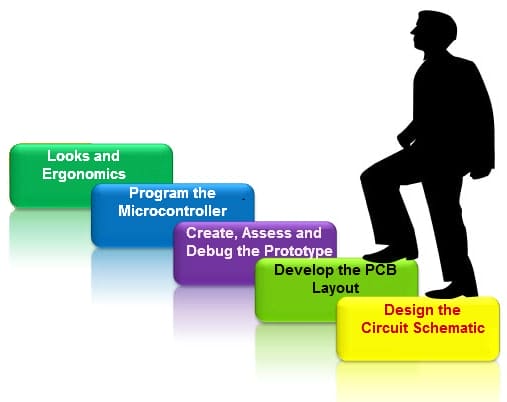

Although it may seem somewhat challenging and expensive to figure out where you should start, getting assistance from an experienced product development company will be beneficial. We have a team of expert professionals who will make sure to build a durable, feasible, and powerful prototype model that will be a replica of the actual product you have in mind. Our electronic product development team follows a precise, effective, and efficient prototype development process. Some of the main factors that are included in our quality electronic prototype development are as follows:

Create The Schematic

Well, creating or designing a schematic diagram or blueprint of the product is the first step when developing a prototype model for an electronic product. If you want to get your prototype made the way you imagined it, then it is essential thing to cover every possible detail in the blueprint or schematic as the product development team will take it as their reference for the development. One should also highlight the different modules and components that are connected.

Develop A Basic Prototype Model

At first, it can be beneficial if you can guide your development team to develop a basic prototype model of your electronic product. Using breadboards and PCBs, it will be possible to cover the basic idea of how your electronic product will function and perform. However, it totally depends on your budget and the type of electronic product you want to develop. But if you have a product with advanced requirements, our prototype development team may suggest you go with some advanced modules like Raspberry Pi and Arduino.

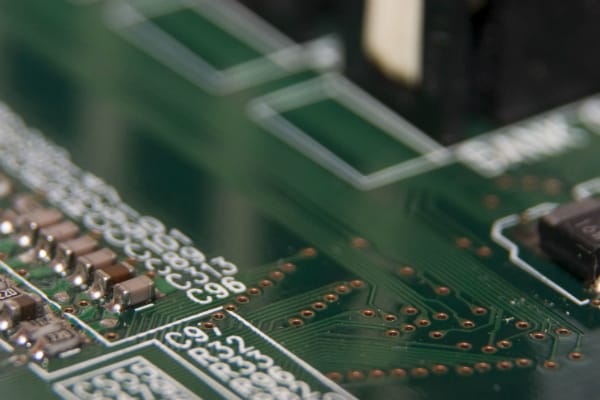

PCB Layout

When you opt for quality prototype development, you will surely have to create the electronic circuit on PCB. As you know, a PCB will hold and connect all the electronic components, and thereby, one can determine if the electronic product will work or not. If you have any kind of customized requirements about the functionality of the product, then you should make it clear to the prototype development team.

Fabrication of the PCBs & Assembly of the Electronic Components

Once the product components and circuit are tested on the PCB layout, then you will just have to send a green signal to your prototype development partner, to begin developing a prototype model for your electronic product. However, you will have to keep track of the prototyping, fabrication, and assembling of the electronic product. When the fabrication of the PCBs is completed, the next step in the prototype development cycle is to assemble the various components on the PCB. For more information about prototype development, kindly consult with a prototyping expert.

Schedule A Friendly Consultation Now For Electronic Product Prototype Development in California

Being one of the best electronic prototype development companies in California, GID Company can help with building agile and functional prototype models as per your bespoke requirements. Whether you need us to craft basic prototype models or an advanced integrated electronic prototype development, our professionals will make sure to offer you quality prototyping and testing.

If you have a unique product idea and if you are willing to develop a high-quality prototype model, please contact our professional engineers and experts by calling us at +1714-323-1052. In case, you want to go through the latest updates and information on our services and prototype development, kindly follow us on social media – Facebook, Twitter, Instagram, LinkedIn, and YouTube.