Product prototype development is one of the most crucial steps in the life-cycle of new product development. As the need to build product prototypes faster increased, better techniques were developed, which eventually lead to the inception of rapid prototyping.

Developed by 3D Systems, a company providing comprehensive 3D products and services, rapid prototyping today has revolutionized the product design and development industry, allowing innovators, product designers, industrial engineers, and product manufacturers to rethink their product development approach.

Rapid Prototyping – What is it?

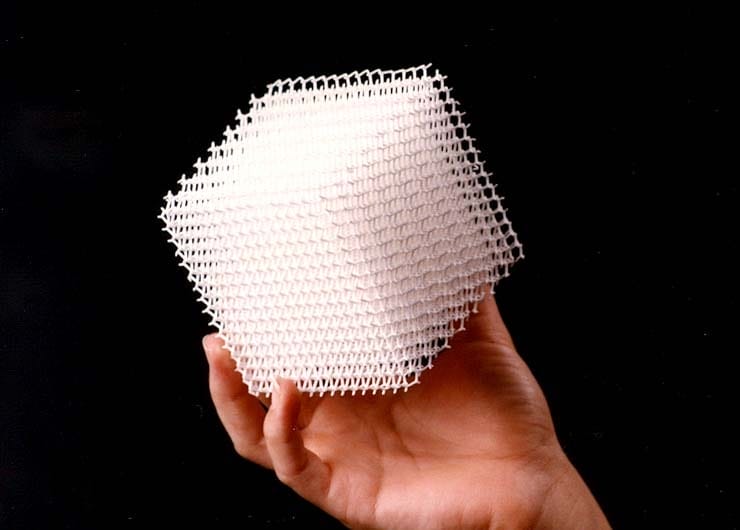

Rapid prototyping is a bundle of techniques, which help in crafting various materials, including plastics and metals, into models that represent the product concept. Rapid prototyping gives innovators, product designers, and industrial engineers the ability to hold, feel, and test as many product prototypes as they need in order to make the final product fully functional and safe to use. Rapid prototyping has ousted the need for conventional casting, molding, or machining in the manufacturing process.

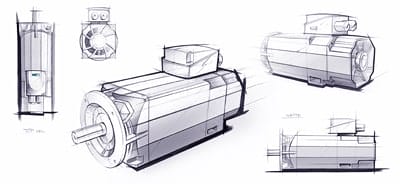

Rapid prototyping is a common term for the process that quickly fabricates a conceived object or product with the help of three-dimensional (3D), computer-aided design (CAD) data. The 3D CAD data is uploaded to a special machine or printer that swiftly constructs the required component. The popular term, “3D Printing” is a prevalent example of the rapid prototyping technique.

Today, the rapid prototyping practice has been widely embraced by product development companies that design and develop electromechanical products, mechanical products, electrical and electronic products, medical device products, sports products, and other complex products.

Advantages of Rapid Prototyping

Due to its ability to construct an object or product quickly with the help of computer data, rapid prototyping is a resourceful tool to build product prototypes in a faster and more efficient way. Innovators rely on product prototypes to prove that their concept really works. By being able to develop their conceived item swiftly, innovators are able to share the concept efficiently with potential stakeholders and manufacturers in a real, tangible form. This is an essential step, also known as “Proof of Concept,” and it is quickly becoming an important standard in the new product development process.

Product prototypes also play a very vital role in detecting any design defects prior to the product manufacturing process. In order to eliminate design defects completely, numerous product prototypes are needed, and rapid prototyping is just able to do that, in a swift and efficient manner. After rapid prototyping an item, defects are detected, which are then corrected, and again a new prototype is created. The process is perpetual until all the design defects are eliminated. Product development companies that employ rapid prototyping techniques are eventually saving their clients substantial sums in product development by repeatedly and swiftly delivering a number of product prototypes, which are worked upon to make the final product better.

Although not a core part of the product development process today, rapid prototyping has begun to help shape and reshape the approach towards new product manufacturing. The revolutionary techniques are making things easier for product prototype development. Product designers, industrial engineers, product development companies, and product manufacturers who have embraced these contemporary techniques are already helping their clients (the innovators) in a much better way.

Need help with rapid prototyping? Perhaps with product design or product development or product manufacturing? Contact GID Development Corporation today.

We are a leading product development company in California, US, and we provide fast, efficient, and economical product design, rapid prototyping, product manufacturing, and other product fulfillment services.

At GID Development Corporation, our product designers, industrial engineers, and other personnel have vast experience and knowledge in bringing product concepts to life. No matter how complex a conceived product is, we will bring it to reality. Whether it is developing an electromechanical product, electrical product, electronic product, mechanical product, medical device product, or any other novel product, we will “GET IT DONE!”

A free 15-minute telephonic consultation is available. Just call Jim Grimes at 714-323-1052 between 8:00 AM to 5:00 PM PST.