Do you have a new product idea that can hike your profit margin and simultaneously wow the world? If yes, then what are you waiting for? Contact a reliable product development with your idea today.

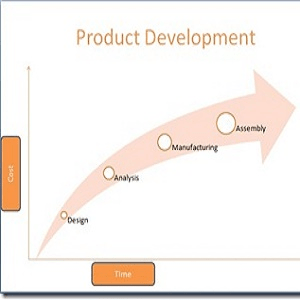

The process of new product development begins with an idea, a striking new product idea or an improvement in the concept of an existing product (in terms of features and appearance). However, manufacturing a new product is a complicated job and not everyone’s cup of tea. More often than not, researchers and inventors believe that great ideas are all that they require developing moneymaking products, which is very short sighted. For developing great products that can stir the market in your favor, you need detailed research and a strategically defined product development process.

When planning to develop new product for your targeted customers, do not forget to analyze their requirements. Before you schedule anything, ask yourself:

- What features are required to make your product different from similar products existing in the market?

- What will be your product’s unique selling point?

- Does your product require more features and functions?

- Whether the product developed is for the consumer market?

- Or is it being developed for rugged industrial usage?

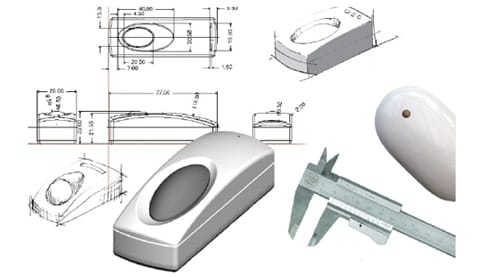

The most important first step in new product development is product specifications. The latter can aid you to think through and pin down the essential product information so that they will help as your directional signs to move ahead in the product manufacturing procedure. Does your product run through electricity, or does it run on batteries? How much power will it consume? How many buttons and keys should it have? In the absence of detailed product specifications, your product idea will probably be fluctuated and subjected to changes and indecision, eventually transforming the product development process into a seriously complicated task. Therefore, be sure to decide and pin down product specifications before you move on with any of the manufacturing steps.

On the occasion, if you are not sure that your concept will work or not, then a feasibility study is recommended by the experts. Let’s say, for instance, your concept is to miniaturize the mobile phone into a wearable gadget, say a smart watch, then you need to undertake a technical or feasibility study to conclude whether it is possible or not. Are there any appropriate batteries small enough to support standard phone usage, but tiny enough to be able to fit into the smart watch? Where to find other components, and which operating system will be powering it? Will all these components be small enough to fit into the smartwatch? Let’s consider that you found all those tiny components needed for manufacturing a smartwatch, but what about the cost of the components? Is the overall manufacturing cost feasible or not?

Another important aspect to consider in the manufacturing strategy is the number of items you are going to produce in the first batch. Are you going to produce the first batch only for marketing purpose? How many units will you develop for promoting your product? Your product manufacturing strategy will determine the type of the product development process that you will need to employ. Are you going to use low volume manufacturing process, or will you use high volume techniques?

Staying focused and proactive is the way to successful new product design and development. A proactive approach from the very beginning can save time and money. In this ever competitive world, understand what your customers require and try to keep them happy.

For more than two decades, GID has been in the product design and development business in California. We have comprehensively done hundreds of product design and development projects for different industries. For more information on product development services in California, contact us at https://www.gidcompany.com/contact-us.