Product Development Process

Expert Guide for Product Development Life Cycle

A product development journey can be both exhilarating and challenging. At GID Company, we provide an expert guide through each step of this complex process, ensuring that your product not only reaches the market but also thrives in it. Our comprehensive approach combines industry insight, technological expertise, and a tailored strategy to transform your vision into reality. With GID Company as your partner, you gain access to a team of experts dedicated to every phase of your product development journey.

Conceptualization and Feasibility Analysis

The journey begins with an in-depth analysis of your product concept. We evaluate the feasibility of your idea in the current market landscape, considering factors like consumer demand, competition, and potential profitability. This stage sets the foundation for a product that is not only innovative but also commercially viable.

This includes:

– Brainstorming innovative ideas that address market gaps or unmet needs.

– Considering factors such as feasibility, market potential, and alignment with business goals.

– Conducting initial market research to validate concept viability.

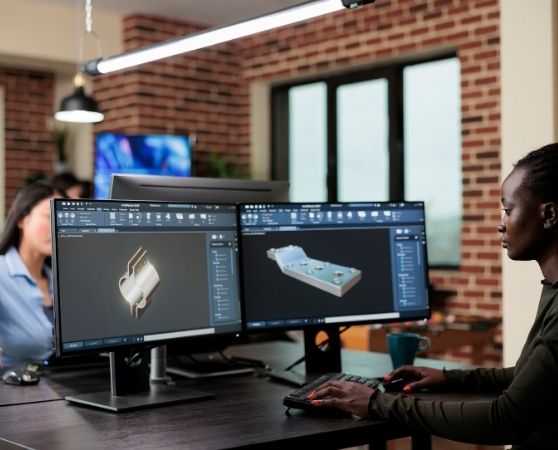

Design and Prototyping

Utilizing the latest in CAD software and 3D modeling, our design team crafts detailed prototypes that bring your ideas to life. This phase is crucial for visualizing the product and testing its functionality in a real-world scenario. Our iterative prototyping process allows for refining product designs based on feedback and performance, ensuring the final product is optimized for user experience and manufacturability.

Engineering and Technical Development

Our engineering team takes over to develop the technical aspects of the product, focusing on durability, efficiency, and compliance with industry standards. Whether it’s integrating electronic components or ensuring mechanical reliability, we handle all aspects of product development phases, technical challenges with precision and expertise.

From Idea to Reality - Watch How We Do It!

Regulatory Compliance and Testing

Navigating the regulatory landscape is critical for ensuring that your product meets all legal requirements before it hits the market. As as leading product development company in California, we manage compliance testing and certification processes, working with regulatory bodies to secure necessary approvals. This approach guarantees that your product is safe, reliable, and ready for consumer use.

Manufacturing and Scale-Up

Transitioning from prototypes to mass production is a pivotal phase in the product development journey. Our team assists in selecting the right manufacturing processes and facilities that match your budget, quality, and volume requirements. We ensure that the production phase is seamless, cost-effective, and timely, with ongoing quality control to maintain high standards.

Market Launch and Post-Launch Support

Launching your product into the market involves strategic planning and execution. We support you in crafting effective marketing strategies and distribution channels to maximize reach and impact. Post-launch, we continue to offer support to adapt the product based on consumer feedback and evolving market trends, ensuring sustained success and growth.

Let's Bring Your Product Vision To Life

Don't let your vision remain just an idea. Contact us today and let's start building the future of your product.

Continuous Innovation and Improvement

Our commitment extends beyond the initial launch. We believe in continuous innovation and routinely assess the product and its performance in the market to identify opportunities for improvement and adaptation.

This includes:

– Proactive Research and Development

– Iterative Design and Feedback Loops

– Quality and Performance Monitoring

– Customer-Centric Enhancements

– Sustainable and Ethical Innovations

– Training and Development for Our Team

At GID Company, continuous innovation and improvement are not just policies but practices woven into the fabric of our operations. We are committed to delivering products that excel in a dynamic market and strive to improve continuously, ensuring long-term success and customer satisfaction.

Pre Mass Production

Before a new product is completely ready for high volume mass production it may be advisable to provide small volume pre mass production runs (500 to 10,000 units per run) to get the product in the hands of end-users for market research, price validation and product performance feedback. This low volume manufacturing can be arranged to be supplied from offshore and sometimes domestic sources. Cost effective and price competitive pre-mass production can be provided by GID Company that will keep our client on and even playing field with the competition.

Sales & Marketing

GID Company can assist with the market preparation for the new product with design and sourcing of logos, packaging, and sales collateral. Packaging design can make or break the successful marketing effort for a new or improved product. For those products eventually headed for the mass retail market, certain packaging requirements must be adhered to. For those clients who want to either test market or go to market via the internet we can also design and manage a website for them including product fullfillment.

The website marketing approach is a way of generating the documented sales history, product acceptance and pricing validation that is required by the mass retailer product category buyer fraternity. E. Again, we can use the 3D CATIA models in sales and marketing materials to further keep costs down by eliminating or reducing costly photography for product launch.

Mass Production

The transition from low volume pre-mass production to high volume mass production must be carefully planned for and managed. Coordination of all manufacturing facets with the marketing and distribution requirements can determine the success or failure of the transition.

In addition to the design and sourcing of high volume mass production tooling, fixtures, and manufacturing procedures, The most trusted product development company, GID Company can also arrange for the offshore manufacture of your product and import it packaged and ready for market. For those clients who wish to establish their own manufacturing operations, GID Company can create the complete manufacturing process.

Not Sure Where To Start?

Call JIM

Product Line Expansion & Improvements

Once the initial new product has proven market acceptance the opportunity to expand it into a full product line is often desired. Many of the design and development processes utilized for the initial product can efficiently and cost effectively be reutilized and expanded to accommodate a product line expansion and/or improvement. This benefit is provided through the effective utilization of the Product Life Cycle Solutions from IBM and the suite of design tools provided in CATIA V5 virtual design software.

With GID Company as your partner, you gain access to a team of experts dedicated to every phase of your product development journey. From conceptual sketches to customer satisfaction, we are here to guide you through each challenge with confidence and expertise. Let us help you navigate the path to successful product development and market leadership.

Frequently Asked Questions - FAQs

-

What are the 5 P's of product development?

The 5 P’s of product development Product, Price, Place, Promotion, and People—represent essential elements needed to successfully develop and market a product. At GID Company, our Product Development Guide is built to help you align each of these areas with your product vision. We offer strategic planning, design, prototyping, and production support to ensure a cohesive and market-ready launch.

-

What are the 7 NPD processes?

The 7 New Product Development (NPD) processes include idea generation, idea screening, concept development, business analysis, product development, test marketing, and commercialization. GID Company simplifies each stage through its comprehensive Product Development Guide, giving you a step-by-step roadmap and professional support to transform ideas into successful products.

-

What are the 7 C's of strategy?

The 7 C’s Customer, Competitors, Capabilities, Cost, Channels, Communication, and Change form the foundation of a strong product development strategy. GID Company leverages these principles to help clients identify market needs, beat the competition, and innovate successfully. Our Product Development Guide ensures your strategy is complete, from concept to commercialization.

-

What is meant by product development?

Product development refers to the full process of bringing a new product to market—from ideation, design, and prototyping to testing and final manufacturing. At GID Company, we specialize in turning ideas into innovative, manufacturable products. Our Product Development Guide outlines each step, backed by our experienced engineering and manufacturing teams.

-

What does a product developer do?

A product developer is responsible for turning ideas into functional products. This includes conceptualizing, designing, testing, and iterating prototypes before launching a finished product. GID Company offers you an experienced product development team that acts as your technical partner throughout the process using our proven Product Development Guide.

-

Does product development require coding?

Product development may require coding depending on the type of product, especially in software, IoT, or embedded systems. For physical or mechanical products, coding is often part of prototyping and functionality testing. GID Company offers multidisciplinary expertise, including software and firmware development, as part of our complete Product Development Guide.

-

What is a product development strategy?

A product development strategy outlines the plan and actions for turning a product idea into a market-ready solution. It includes research, design, budgeting, prototyping, testing, and marketing. GID Company helps define and execute your strategy through a tailored Product Development Guide that minimizes risk and maximizes your product’s success potential.