28 Feb 2014

Factors to Consider Before Custom / New Product Development

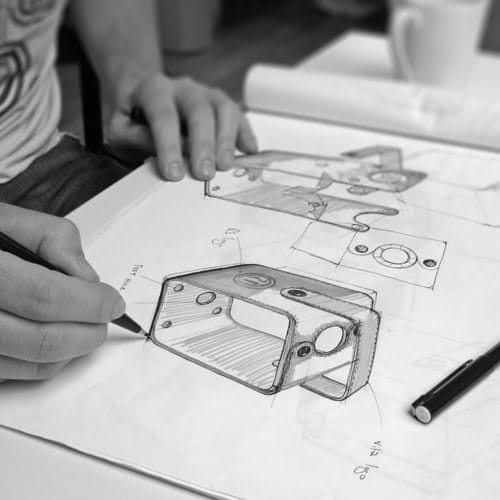

About Custom New Product Development “Custom New Product Development” is the complex process of designing, prototyping, and manufacturing a new product from...