30 Nov 2014

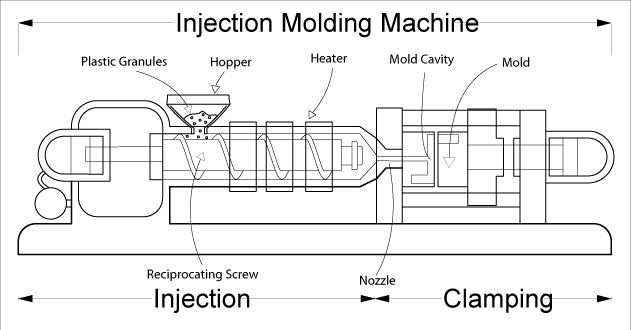

Why Injection Molding Method is the Best Process for Plastic Product Manufacturing

According to Plastic product manufacturers across the globe, injection molding method is the best and the most reliable method for plastic product...