27 Nov 2015

Essential Tips on Prototyping Your New Product

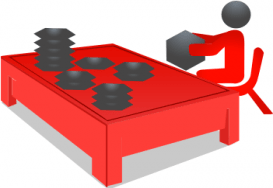

The most important step that follows after conceiving a brilliant new product idea and creating a viable product design is prototyping your...