Additive manufacturing is reshaping how American businesses approach innovation, from early design to full-scale production. Across states like California, Texas, Florida, Utah, Arizona, and Georgia, companies are using this transformative approach to build smarter, faster, and with greater precision.

At GID Company, we help turn ideas into tangible realities through modern engineering tools and agile production frameworks. Additive manufacturing gives our clients the flexibility to iterate quickly, eliminate unnecessary tooling, and reduce production costs without compromising quality.

This evolution is not just about keeping up with technology—it’s about creating competitive advantages. Through integrated solutions and data-driven development, GID Company enables teams to bring their best designs to market with confidence and speed.

Additive Manufacturing: Strategic Advantages We Deliver

When teams embrace additive manufacturing, they gain new creative freedom and control over production timelines. GID Company brings this potential to life for innovators across the United States, ensuring every step—from design to delivery—is optimized for performance, precision, and scale.

Redefining the Design Cycle

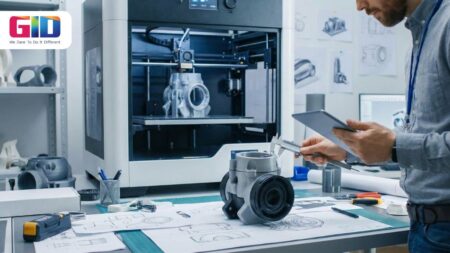

Traditional development cycles often trap teams in lengthy loops of revisions and tooling adjustments. Additive manufacturing disrupts this cycle by allowing instant testing of physical designs using 3D printing technology.

At GID Company, we help clients move from CAD concepts to physical parts within days. This process reduces guesswork and accelerates approvals. It also helps identify design flaws early, saving both time and resources before major investments are made.

By integrating rapid prototyping into early design reviews, engineers can visualize performance, explore new materials, and validate functionality faster than ever. It’s not just speed—it’s smarter decision-making backed by real-world testing.

Reducing Risk with Precision Planning

Risk management is a core part of any product development process. Additive manufacturing helps minimize uncertainty by providing detailed feedback at every stage of production. GID Company applies industrial 3D printing to produce accurate, functional prototypes with consistent mechanical integrity.

This process reduces dependency on traditional tooling and mitigates the financial impact of design changes. Our engineers collaborate closely with clients to fine-tune part geometry, evaluate performance under stress, and ensure each iteration delivers measurable improvements.

The result is greater control over outcomes and less rework during final production—helping businesses stay agile even in high-demand environments.

Where Additive Fits in Your Process

Additive manufacturing can serve multiple roles depending on your business goals. It’s ideal for bridge production, small-batch fabrication, and complex geometries that are difficult to achieve with conventional methods.

At GID Company, we integrate advanced manufacturing techniques that complement existing workflows. This hybrid model allows clients to move seamlessly from prototype to scalable production while maintaining consistent quality and traceability.

Whether you’re based in Arizona, Utah, or Georgia, our teams provide localized expertise and streamlined execution, ensuring your parts are manufactured quickly and accurately.

Tangible Impact Across U.S. Industries

Across diverse sectors—from aerospace and automotive in Texas to healthcare and consumer products in Florida—additive manufacturing has become a vital innovation driver. GID Company empowers these industries to build faster, reduce waste, and deliver higher-performing components to market.

Through the combination of 3D printing technology, rapid prototyping, and industrial 3D printing, we create opportunities for design evolution and cost efficiency. Each project benefits from detailed planning, hands-on collaboration, and an unrelenting focus on quality.

With advanced manufacturing techniques and regional support, GID Company ensures that American innovators remain at the forefront of product development—turning bold ideas into market-ready successes.

3D Printing Technology in Early Design Validation

In the early stages of product design, speed and accuracy determine how quickly ideas evolve into market-ready solutions. At GID Company, we use 3D printing technology to help U.S. businesses accelerate this process through real-time validation, precise modeling, and efficient feedback loops. This approach blends creativity with engineering precision, giving teams across California, Florida, Texas, and other innovation-driven states the power to make informed design decisions faster.

CAD-to-Part in Days with 3D Printing Technology

Traditional design reviews often rely on digital simulations that can’t fully represent a part’s form or function. By using additive manufacturing and 3D printing technology, GID Company bridges this gap. Our engineers turn digital files into physical models within days, allowing clients to interact with real components during the earliest stages of product development.

This fast turnaround is especially valuable for companies that need to test ergonomics, verify tolerances, and review product aesthetics before committing to tooling. GID Company ensures each prototype accurately reflects design intent, creating a smooth path toward production without costly delays.

Shorter cycles also foster collaboration. Design teams can evaluate performance immediately, share real-world data, and refine products with greater confidence. It’s a complete shift from theory-based decision-making to evidence-based innovation.

Materials and Properties Overview

The choice of materials plays a major role in how effective a prototype can be. Through additive manufacturing, GID Company provides access to a broad range of materials—from high-performance polymers to metal composites. Each material serves specific mechanical, thermal, and aesthetic needs, helping teams align prototypes with the final product’s intended performance.

Our experts analyze stiffness, surface quality, and temperature resistance to ensure that every printed component performs as expected during testing. Whether the application demands lightweight flexibility or structural strength, 3D printing technology delivers solutions tailored to the project’s requirements.

By combining rapid prototyping and advanced manufacturing techniques, GID Company ensures material performance aligns with production readiness. This connection between design and engineering eliminates unnecessary iterations and keeps timelines predictable.

GID Company Integration

Successful product development depends on seamless integration between design, engineering, and production. GID Company creates an environment where additive manufacturing works hand in hand with digital design systems, ensuring secure data exchange and revision control.

Our approach allows for real-time updates and traceable modifications, helping clients maintain version accuracy across teams. With structured design validation workflows, we turn 3D printing technology into a core component of every development cycle.

This process is especially valuable for distributed teams in states like Utah, Arizona, and Georgia, where local production facilities and centralized oversight keep projects aligned from start to finish.

Rapid Prototyping to De-Risk Decisions

Every successful product journey starts with clarity and confidence. Rapid prototyping provides that clarity by turning digital ideas into tangible parts early in the development phase. At GID Company, we use additive manufacturing to give clients across the United States a faster, more reliable path to final production.

Rapid Prototyping to Speed Approvals

Design approvals often stall when stakeholders can’t visualize final products. With rapid prototyping, GID Company accelerates decision-making by offering physical prototypes that showcase every detail—from texture to function. Using 3D printing technology, our engineers produce these prototypes quickly and cost-effectively, allowing teams to test and evaluate without waiting weeks for tooling.

This agility enhances collaboration between designers, engineers, and executives. Everyone can hold, test, and analyze the product, identifying opportunities for improvement before full-scale production begins. Additive manufacturing makes this process both accessible and scalable, helping teams validate multiple design options in parallel.

Iteration Cadence

Innovation thrives on iteration. GID Company structures development into focused cycles—concept, alpha, beta, and pre-pilot—each supported by additive manufacturing and rapid prototyping. These stages allow for incremental refinement while maintaining consistent design intent.

By leveraging industrial 3D printing, we help teams test structural integrity, performance under stress, and overall manufacturability. Each iteration becomes a learning step that builds toward a better, more refined end product. The ability to make quick adjustments minimizes risk and ensures each phase aligns with real-world manufacturing constraints.

This iterative rhythm also benefits industries in states like California and Texas, where time-to-market pressures are high. With every prototype, GID Company delivers measurable progress, clearer insights, and more confident decision-making.

What You Get from GID Company

GID Company’s approach goes beyond just making parts—it’s about supporting the entire development ecosystem. Through additive manufacturing, our engineers provide clients with detailed prototype reports, tolerance analysis, and design improvement recommendations that inform every next step.

Each prototype is backed by thorough documentation and data-driven insight, ensuring the transition to full production is seamless. Whether using industrial 3D printing for functional testing or advanced manufacturing techniques for pre-production validation, GID Company ensures results that are consistent, repeatable, and aligned with your goals.

By bringing together rapid prototyping and digital engineering expertise, we reduce uncertainty and help U.S. companies move forward with confidence. Every iteration delivers value, every decision carries clarity, and every product moves closer to success.

Industrial 3D Printing for Production-Grade Parts

Industrial 3D printing has evolved from a prototyping tool into a reliable production method. Across industries, manufacturers now rely on additive manufacturing to create complex, durable parts that perform consistently under demanding conditions. At GID Company, we use this technology to help clients across the United States—particularly in California, Texas, and Georgia—achieve precision, repeatability, and speed in their production cycles.

When Industrial 3D Printing Makes Sense

Industrial 3D printing is ideal for low-to-medium-volume production runs and parts that demand intricate geometries or lightweight designs. GID Company guides businesses in selecting when and where additive manufacturing can replace or enhance traditional methods.

For example, components with internal channels or lattice structures can be built directly using 3D printing technology without the need for assembly. This reduces material use and eliminates joints that might weaken performance. The result is stronger, lighter, and more efficient components, all produced with consistent quality across every batch.

Beyond mechanical advantages, the real benefit lies in speed. Projects that once required months to tool and validate can now move through design validation and production in a fraction of that time. By integrating rapid prototyping and industrial 3D printing, GID Company helps companies launch products faster and respond quickly to market shifts.

Metals and Engineering Polymers

The materials used in additive manufacturing have matured to rival traditional metals and plastics in performance and durability. GID Company offers an array of options, from high-strength metals like aluminum and stainless steel to advanced engineering polymers suitable for high-temperature or load-bearing applications.

Material selection depends on the intended function of the part. Industrial 3D printing allows for optimal material use—reducing waste while maintaining exact specifications. Our engineers analyze stress points, fatigue life, and environmental exposure to ensure every part meets operational demands.

When paired with advanced manufacturing techniques, these materials deliver production-ready results without the compromises typically associated with short-run manufacturing. GID Company manages each project from design intent through post-processing to ensure dimensional accuracy and structural reliability.

GID Company’s Production Support

Production doesn’t end when the part is printed—it begins there. GID Company provides full lifecycle support for additive manufacturing projects, including quality verification, finishing, and functional testing. Our facilities follow documented processes that ensure every component aligns with our clients’ regulatory and performance standards.

Using industrial 3D printing, we provide serial production with batch tracking, dimensional validation, and traceable material records. This level of detail enables our clients in sectors such as aerospace, energy, and medical devices to meet industry-specific compliance requirements.

From concept to scale, GID Company ensures that additive manufacturing delivers not only precision but also consistency and accountability. Every project reflects a partnership built on transparency and results.

Advanced Manufacturing Techniques: Hybrid Workflows That Scale

The most powerful results emerge when new technologies complement proven ones. GID Company combines additive manufacturing with advanced manufacturing techniques to create hybrid workflows that bridge the gap between prototype and production. This balanced approach allows our clients across Florida, Utah, and Arizona to scale efficiently while maintaining quality and performance.

Pairing Advanced Manufacturing Techniques with Traditional Methods

Additive manufacturing offers flexibility and innovation, while traditional machining and molding bring scalability and precision. GID Company merges these strengths by strategically applying 3D printing technology where it adds the most value—whether in tooling, fixtures, or final components.

Our engineers design parts that leverage the unique benefits of both methods. For instance, intricate internal structures can be printed directly, while exterior features requiring fine tolerances are machined post-print. This integration reduces lead time and ensures repeatable outcomes.

The combination of rapid prototyping and conventional production tools enables smoother transitions through development stages. GID Company uses hybrid workflows to help clients ramp up from pilot runs to full-scale manufacturing without redesigning or requalifying their parts.

DFAM and DFM Combined

Design for Additive Manufacturing (DFAM) and Design for Manufacturability (DFM) principles guide every stage of our process. GID Company ensures products are optimized for both additive production and high-volume fabrication. By merging these methodologies, we help clients avoid costly redesigns and material inefficiencies.

Our engineers use additive manufacturing early in development to validate part geometry, assembly alignment, and weight optimization. Once validated, those same components transition into production lines supported by advanced manufacturing techniques. This continuity reduces production risk and maintains quality consistency across every batch.

With a focus on practical scalability, GID Company ensures that 3D printing technology doesn’t end at the prototype phase—it becomes a foundation for long-term manufacturing success.

GID Company Transition Plans

Scaling production requires careful coordination between digital design, additive workflows, and traditional processes. GID Company offers structured transition plans that help clients move seamlessly from concept models to production-ready assemblies.

By using industrial 3D printing for early validation and incorporating traditional methods for final scalability, we eliminate disconnects between prototype and mass production. This approach ensures that designs maintain their intent while adapting efficiently to larger production volumes.

For clients across U.S. regions—from aerospace innovators in Texas to medtech developers in Florida—GID Company provides reliable, repeatable solutions that merge precision with practicality. Our expertise in advanced manufacturing techniques ensures every project benefits from the best of both worlds: the innovation of additive manufacturing and the dependability of traditional production.

Regional Execution: How We Serve CA, TX, FL, UT, AZ, and GA

Additive manufacturing is transforming regional production strategies across the United States. GID Company provides localized expertise and technical execution for clients in California, Texas, Florida, Utah, Arizona, and Georgia—delivering faster lead times, lower logistics costs, and consistent quality. Each state presents its own manufacturing strengths, and GID Company tailors additive workflows to suit each region’s industry focus.

California and Texas

California and Texas are innovation leaders in aerospace, energy, and electronics. GID Company supports these sectors by integrating additive manufacturing into product development pipelines that demand agility and compliance.

In California’s fast-moving tech ecosystem, 3D printing technology allows our clients to validate designs and adapt to evolving requirements rapidly. Meanwhile, manufacturers in Texas benefit from industrial 3D printing applications that streamline supply chains and support on-demand part replacement. The flexibility of additive production gives these industries the freedom to experiment without disrupting operations or increasing cost overheads.

Florida and Georgia

Florida and Georgia are emerging hubs for advanced product development in defense, healthcare, and logistics. GID Company empowers these industries with rapid prototyping and early-stage validation to accelerate certification processes.

Using additive manufacturing, our engineers produce complex components tailored to specific regulatory and functional needs. The combination of rapid testing and precision production enables faster product launches and ensures compliance with industry standards. By integrating advanced manufacturing techniques, GID Company helps companies in Florida and Georgia maintain agility even under strict performance requirements.

Utah and Arizona

Utah and Arizona are known for aerospace innovation, outdoor products, and electronics manufacturing. GID Company provides these industries with agile, additive-based production solutions that reduce waste and support sustainable growth.

Our team leverages 3D printing technology to produce parts that meet mechanical and thermal specifications while minimizing cost and lead time. By combining rapid prototyping with industrial 3D printing, GID Company supports local businesses in maintaining production continuity and scaling effectively.

Multi-Site Coordination

With multiple regional partners and coordinated fulfillment strategies, GID Company ensures consistent standards across every facility. Our centralized project management system keeps teams in sync, while additive manufacturing capabilities provide the flexibility to shift production between sites based on demand.

This regional execution model reduces downtime, optimizes material usage, and delivers products faster to U.S. markets. GID Company’s approach ensures that each client, regardless of location, benefits from the same precision and reliability.

Quality, Compliance, and Sustainability Built In

The success of additive manufacturing depends not only on innovation but also on reliability. GID Company prioritizes quality assurance, compliance, and sustainability in every project. We integrate detailed verification steps, standardized protocols, and environmentally responsible methods to ensure long-term value for our clients.

Verification and Validation

Every part produced through additive manufacturing undergoes rigorous validation. GID Company follows structured inspection processes that include dimensional measurement, surface analysis, and mechanical performance evaluation.

By using industrial 3D printing for part creation, our engineers maintain tight tolerances that meet or exceed traditional manufacturing standards. Whether it’s aerospace-grade accuracy or consumer-level refinement, our systems ensure that each component performs as designed. This commitment to verification gives our clients full confidence before scaling into production.

Sustainability Gains

Sustainability is a core advantage of additive manufacturing. Unlike traditional methods that remove material through cutting or milling, this process builds parts layer by layer—minimizing waste. GID Company uses 3D printing technology and advanced manufacturing techniques to optimize resource use, reduce scrap rates, and cut energy consumption.

This efficiency doesn’t just lower costs; it strengthens environmental responsibility. Our engineers analyze part geometry and material utilization to balance strength, durability, and sustainability. The result is a smarter production cycle that supports both profitability and ecological stewardship.

GID Company Assurance

Trust and consistency define our approach. GID Company’s additive manufacturing framework includes traceable documentation, audited workflows, and secure data handling. These measures protect intellectual property and ensure compliance across regulated industries.

From concept to production, clients rely on GID Company for transparent communication and repeatable quality outcomes. Our combination of rapid prototyping, industrial 3D printing, and advanced manufacturing techniques ensures that every product meets the highest performance standards while remaining cost-effective.

Budgeting and ROI: Making the Numbers Work

Financial performance is at the heart of every product strategy. GID Company helps clients calculate and maximize the return on investment from additive manufacturing by balancing speed, cost, and long-term value.

Total Cost of Validation

One of the biggest financial advantages of additive manufacturing lies in its ability to reduce upfront tooling expenses. By integrating 3D printing technology into early-stage validation, GID Company enables teams to iterate designs without incurring tooling or mold fabrication costs.

This flexibility significantly lowers the total cost of validation. Projects that once required multiple prototype revisions now achieve final approval faster and with less material waste. The financial benefit compounds over time, as improved accuracy during rapid prototyping prevents costly downstream rework.

Practical Cost Models

Each client’s economic model is unique. GID Company provides clear, data-driven insights to compare additive manufacturing costs with conventional production methods. Using industrial 3D printing, we identify the most cost-efficient production volumes, helping clients determine break-even points for low- and mid-scale runs.

Our engineers evaluate design complexity, material usage, and production frequency to recommend the optimal strategy. The result is a transparent cost framework that aligns technology investment with tangible business outcomes.

GID Company Estimates

From initial consultation to final delivery, GID Company ensures full pricing transparency. We present clients with multiple quote options that reflect different timelines, finishes, and production goals. Whether utilizing rapid prototyping for early validation or scaling up with advanced manufacturing techniques, each proposal is designed to maximize value while minimizing risk.

This strategic approach allows companies across California, Texas, Florida, and beyond to integrate additive manufacturing confidently into their business models. With measurable ROI and reduced operational barriers, GID Company makes high-quality production both achievable and financially sound.

Wrapping Up: Your Next Step with GID Company

Additive manufacturing has reshaped how American industries approach innovation and product realization. For companies across California, Texas, Florida, Utah, Arizona, and Georgia, it’s not just a technological upgrade—it’s a strategic advantage. GID Company delivers that advantage through precision engineering, adaptive design systems, and regionally coordinated production support.

By integrating 3D printing technology with traditional engineering processes, GID Company helps businesses shorten development timelines and enhance flexibility. Every prototype and production run benefits from data-backed decisions, optimized materials, and consistent quality control. This synergy of innovation and execution ensures that products move from concept to market without unnecessary friction or cost.

Our approach combines rapid prototyping and industrial 3D printing with advanced manufacturing techniques to create a streamlined, repeatable workflow. Each project begins with collaboration and ends with performance-tested solutions that meet exact client specifications. GID Company bridges creativity with manufacturing intelligence—delivering measurable results and setting new standards for efficiency and design freedom.

For businesses ready to modernize their product development strategies, the next step is clear. GID Company offers tailored additive manufacturing programs that scale with your growth, adapt to your needs, and help you stay ahead in today’s competitive landscape.