Circular economy product design is redefining how businesses create, use, and recover value from their products. It’s a shift from the old linear model of take-make-dispose to a regenerative system that eliminates waste and extends product life.

Across California, Florida, Texas, Utah, Arizona, and Georgia, industries are under increasing pressure to balance innovation with environmental accountability. GID Company supports this transformation by embedding circular thinking into every step of the development process — from initial concept to recovery and reuse.

At GID Company, we treat sustainability as a design objective, not an afterthought. By planning for a sustainable product lifecycle from the outset, we help clients build durable, adaptable, and resource-efficient solutions that align with both their business goals and regional regulations. This approach ensures that products perform better, last longer, and maintain value through every stage of their journey.

Circular Economy Product Design: Our End-to-End Playbook

Circular economy product design at GID Company is built on a structured yet flexible framework. It’s how we guide clients through the transition from traditional manufacturing to a system where materials, components, and energy remain in circulation for as long as possible.

Our expertise spans across California, Florida, Utah, Texas, Arizona, and Georgia — states leading the charge toward greener, more efficient production. Through this regional insight, we deliver practical solutions that merge environmental responsibility with real-world business needs.

From Concept to Creation

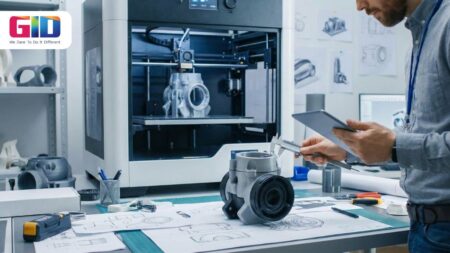

At the concept stage, GID Company integrates eco-design principles directly into early ideation. Every design decision considers the entire sustainable product lifecycle — from material sourcing and manufacturing efficiency to end-of-life recovery.

We analyze multiple design pathways to identify which materials and configurations offer the best balance of performance, durability, and recyclability. This early integration allows our clients to minimize waste long before a product reaches the market.

Our engineering teams model components for disassembly, repair, and modularity. This approach not only makes circular product innovation achievable but also ensures that future updates or replacements can be implemented without starting from scratch.

The Six-Gate Circular Workflow

To make circularity tangible, GID Company follows a structured six-gate workflow: Discover, Define, Design, Validate, Launch, and Recover. Each phase is designed to progressively integrate sustainability without compromising technical or commercial performance.

In the Discover phase, we identify material inefficiencies and lifecycle bottlenecks. During Define, we translate those findings into actionable sustainability goals and measurable KPIs.

The Design and Validate stages introduce closed-loop product design, creating products that can be easily disassembled, repaired, or remanufactured. Once validated, the Launch phase ensures that manufacturing aligns with our circular objectives. Finally, in the Recover stage, we establish systems to bring materials and components back into the production loop.

This method transforms how companies think about end-of-life management — turning disposal into opportunity.

Regional Integration and Supply Chain Synergy

A successful circular system relies on a strong regional ecosystem. GID Company helps manufacturers build localized recovery and distribution networks throughout Texas, Arizona, and Georgia.

By aligning suppliers, logistics partners, and recyclers, we ensure that materials circulate efficiently and maintain quality through multiple lifecycles. This model also helps clients reduce transportation costs and emissions — key components of a sustainable product lifecycle.

Each solution is tailored to regional capabilities. For instance, we design packaging recovery systems in Florida, enable modular refurbishment centers in California, and support renewable material sourcing in Utah. Through this synergy, circular economy product design becomes a scalable, profitable practice.

Digital Tools That Power Circular Systems

Technology plays a critical role in our approach. GID Company uses digital product passports to track material histories, maintenance data, and recovery rates throughout a product’s life.

These insights help clients manage sustainable product lifecycle performance with precision. When paired with real-time analytics, the data uncovers new opportunities for circular product innovation — from material substitution to secondary market expansion.

This digital backbone enables accountability and transparency, allowing our partners to prove compliance, trace materials, and strengthen their environmental credentials.

Continuous Innovation and Evolution

Circular economy product design is not a one-time project — it’s an ongoing process of evolution. GID Company continuously monitors data from product use and recovery to refine and optimize designs for future iterations.

We work closely with clients to adjust materials, enhance assembly methods, and plan upgrades that fit within closed-loop product design principles. Whether it’s updating modular components or shifting toward bio-based alternatives, this cycle of improvement ensures long-term sustainability and profitability.

Circular product innovation thrives on flexibility, and GID Company ensures that flexibility is built into every stage. From California’s tech-driven markets to Georgia’s growing manufacturing sector, our regional experience enables businesses to design smarter, greener, and more resilient products that lead the next era of sustainable innovation.

Designing a Sustainable Product Lifecycle That Pays for Itself

A sustainable product lifecycle is the foundation of long-term business viability and environmental responsibility. At GID Company, we design every product with the end in mind—ensuring that materials, processes, and components are optimized for reuse and recovery. This approach reduces waste, lowers production costs, and enhances operational efficiency across California, Florida, Utah, Texas, Arizona, and Georgia.

By embedding sustainability into the earliest stages of design, GID Company enables clients to build profitable systems that maintain value throughout every phase—from sourcing to disposal and renewal. This model supports both cost savings and circular economy product design principles that modern consumers and regulators demand.

Mapping the Lifecycle for Measurable Impact

Understanding the flow of materials and energy is critical to achieving a sustainable product lifecycle. Our teams conduct detailed lifecycle assessments to identify where environmental and financial inefficiencies occur. Once these hotspots are mapped, we implement design changes that extend product durability, enable easier repairs, and improve recyclability.

Incorporating circular product innovation at this stage ensures that products are not just built to last, but also to evolve. Whether the design involves modular electronics, recyclable packaging, or replaceable components, every decision contributes to creating a closed-loop product design that maximizes long-term value.

Turning Waste into Value

A key goal of sustainable product lifecycle design is to turn waste into a resource. GID Company builds recovery and refurbishment systems into the product’s ecosystem. This means that materials can be recaptured and reintroduced into the supply chain instead of being discarded.

In Texas and Arizona, for example, GID Company collaborates with local partners to create return and remanufacturing channels that keep valuable materials circulating. These programs demonstrate how circular economy product design can deliver measurable returns by lowering raw material costs and improving production agility.

Financial Performance Meets Environmental Responsibility

The economic benefits of a sustainable product lifecycle extend far beyond compliance. By designing for reuse, companies can avoid the high costs of virgin materials and waste management. GID Company helps clients quantify these benefits through total cost of ownership models, allowing them to see clear ROI from their sustainability investments.

When coupled with eco-design principles, this strategy leads to more efficient resource use and higher product margins. It also strengthens brand credibility in regions like California and Georgia, where consumers and policymakers increasingly prioritize circular economy product design.

Eco-Design Principles, Simplified and Operationalized

Eco-design principles form the backbone of GID Company’s engineering philosophy. These guidelines ensure that products are developed to minimize environmental impact while maximizing performance and user satisfaction. From early sketches to production, every design decision considers material efficiency, recyclability, and long-term serviceability.

By integrating circular economy product design at this level, we help businesses create smarter, cleaner products that can thrive within a closed-loop economy. Each solution reflects a careful balance between innovation, cost-effectiveness, and sustainability.

Designing for Durability and Adaptability

Durability is the most powerful expression of eco-design principles. Products that last longer generate less waste and deliver higher lifetime value. GID Company engineers each component to endure operational stress, weather conditions, and time—without sacrificing performance or aesthetics.

Equally important is adaptability. Modular construction allows components to be upgraded or replaced without discarding the entire product. This strategy promotes a sustainable product lifecycle by keeping products in service longer and ensuring that users always have access to the latest technology without starting over.

Materials Matter: Choosing Wisely and Responsibly

The choice of materials directly affects the environmental footprint of any design. GID Company prioritizes materials that can be easily separated, recycled, or repurposed at the end of life. Our teams in Utah and Florida focus on sourcing renewable and recyclable alternatives that align with regional supply chains.

Every material decision is guided by circular product innovation—ensuring that the product supports a closed-loop product design where nothing is wasted. By selecting recyclable metals, biodegradable plastics, or bio-based composites, GID Company helps clients meet performance standards while reducing dependency on finite resources.

The Role of Smart Engineering in Circularity

Eco-design is not just about materials; it’s also about how products are built. Smart engineering practices, such as minimizing part counts and simplifying assembly, make products easier to repair and recycle. GID Company employs advanced modeling and simulation tools to predict how each design choice influences lifecycle efficiency and cost.

This approach reinforces a sustainable product lifecycle by enabling fast disassembly, component recovery, and simplified maintenance. When combined with data from real-world usage, these insights fuel continuous circular product innovation—allowing future iterations to perform even better with fewer resources.

Regional Design Workshops and Implementation

GID Company conducts regional design workshops across California, Texas, and Georgia to train engineering teams and clients in applying eco-design principles effectively. These sessions bridge theory and practice, empowering teams to make sustainability-driven design decisions in real time.

Participants learn how to integrate circular economy product design directly into their workflows, ensuring every new product aligns with both environmental goals and market expectations. Through these collaborative programs, GID Company helps organizations build a strong foundation for circular product innovation while maintaining flexibility to adapt to evolving industry standards.

By embedding eco-design principles throughout the design and production journey, GID Company enables businesses across the southern and western U.S. to achieve more than compliance—they achieve leadership. Our process transforms sustainability from an obligation into a competitive edge, proving that smart design is not just about how things look or function, but how they endure and regenerate within the modern economy.

Closed-Loop Product Design: Building the Reverse Path on Day One

Closed-loop product design is the structural backbone of a circular manufacturing ecosystem. It enables companies to recover, refurbish, and reintegrate materials rather than disposing of them. At GID Company, this approach begins on the first day of development, ensuring that every new concept is built for regeneration. By combining engineering precision with sustainability insights, we help businesses across California, Florida, Utah, Texas, Arizona, and Georgia close the loop on waste and extend their products’ usable life.

This process forms a crucial pillar of circular economy product design, guiding how materials are chosen, assembled, and tracked throughout their lifespan. It ensures that a sustainable product lifecycle is not just a goal but a practical, measurable reality.

Designing Products for Reverse Logistics

The key to closed-loop product design is engineering products for easy return, disassembly, and reintegration. GID Company develops products with modular structures and standardized fasteners, allowing components to be separated without damage or contamination. This simplifies recycling and refurbishment, turning what would normally be waste into high-value resources ready for reuse.

By designing products compatible with local collection and repair systems, GID Company ensures clients benefit from an efficient, sustainable product lifecycle. In regions like Texas and Georgia, where manufacturing networks are well-established, these systems are especially effective for creating continuous material circulation.

Our process anticipates the product’s reverse journey—designing packaging, labeling, and tracking to ensure every item can find its way back into the production flow. This proactive planning keeps valuable materials in circulation and supports long-term circular product innovation.

Creating Infrastructure for Product Recovery

A strong circular system requires more than smart design; it depends on infrastructure. GID Company partners with logistics and recycling networks across the southern and western U.S. to establish efficient return channels. These networks enable businesses to retrieve used products and components from consumers, repair or refurbish them, and reintroduce them into the market.

By embedding eco-design principles and circular economy product design into the recovery phase, we help organizations transform waste streams into value streams. This integration reduces the need for virgin materials, cuts energy use, and strengthens regional supply chains.

The success of a closed-loop product design lies in its ability to evolve. GID Company continuously improves the reverse flow by analyzing material performance and collection rates, ensuring that every iteration of the process becomes more efficient and more profitable.

Empowering Local Economies Through Circularity

Closed-loop product design also benefits local economies. By keeping materials and manufacturing within regional loops, states like Arizona and Florida retain value locally rather than exporting waste or importing new raw materials. GID Company’s approach supports job creation in repair, recycling, and logistics while helping manufacturers meet regional sustainability goals.

This method integrates circular product innovation into community-level production, building resilient ecosystems that thrive on collaboration. The result is a network where environmental sustainability and economic growth move hand in hand, proving that circular economy product design can drive both profit and progress.

Circular Product Innovation That Scales Beyond Pilots

Circular product innovation represents the next frontier of industrial transformation. It’s not enough to experiment with small-scale recycling programs—sustainability must scale. GID Company specializes in taking circular concepts from pilot projects to full-scale operations across California, Florida, Utah, Texas, Arizona, and Georgia.

Through a fusion of creativity, data, and engineering expertise, we help companies operationalize innovation across every phase of their sustainable product lifecycle. The outcome is a continuous design loop that keeps products, materials, and ideas in motion—driving lasting environmental and financial gains.

From Prototype to Scalable Circular Systems

GID Company transforms ideas into practical, scalable systems. Our teams start by creating prototypes that demonstrate how circular economy product design can function in real-world production environments. These prototypes are built for disassembly, modularity, and easy maintenance—ensuring that they meet both customer needs and circular economy goals.

Once validated, these designs transition into scalable manufacturing processes. Through optimized tooling, materials recovery systems, and supply chain integration, we enable a smooth shift from linear to circular operations. Every stage of production is guided by eco-design principles, reinforcing durability, reparability, and recyclability without compromising performance.

Digital Integration for Smarter Circularity

Technology plays a vital role in scaling circular product innovation. GID Company uses data-driven tools such as digital product passports and IoT monitoring to track component lifecycles and recovery efficiency. This digital oversight ensures that each product contributes meaningfully to the sustainable product lifecycle by making recovery, reuse, and redesign measurable and traceable.

These insights drive ongoing improvement, allowing GID Company to refine designs based on real-world performance data. The feedback loop between product use, recovery, and redesign ensures that circular economy product design becomes a self-sustaining process, constantly evolving to deliver higher value.

Regional Hubs for Implementation and Growth

Scaling circular product innovation requires regional infrastructure and partnerships. GID Company operates and collaborates with circular design hubs across major industrial centers in California, Texas, and Georgia. These hubs act as testing and deployment sites where products are manufactured, disassembled, and reintroduced into the market under a unified closed-loop product design model.

Each hub strengthens local supply chains and accelerates product turnaround times, ensuring businesses can adapt quickly to changing market demands. This regionalized approach supports a truly sustainable product lifecycle, reducing transportation emissions and improving responsiveness.

The Future of Scalable Circularity

The future of manufacturing depends on flexibility and foresight. GID Company helps businesses future-proof their operations by embedding circular product innovation at the core of their strategies. As materials, technologies, and consumer expectations evolve, this adaptability becomes essential for survival and growth.

By integrating eco-design principles and closed-loop product design into every stage, companies not only achieve compliance but also unlock new revenue opportunities. From material recovery programs in Florida to modular product upgrades in Utah, circular economy product design is no longer an abstract concept—it’s a competitive advantage.

At GID Company, we believe that sustainable success lies in systems that regenerate, not deplete. Through continuous innovation, data-driven design, and regional collaboration, we turn sustainability into a long-term business engine—one that pays dividends for both the planet and the bottom line.

Regulatory Readiness & Market Fit Across Key States

A successful transition to circular economy product design requires a strong understanding of regional policies and market conditions. Regulations across California, Florida, Utah, Texas, Arizona, and Georgia are evolving quickly, placing new expectations on how products are made, used, and recovered. GID Company helps businesses stay ahead by integrating compliance and innovation seamlessly within the design process.

By embedding regulatory readiness into early planning, we make sustainability not just a legal necessity but a driver of value. Our approach ensures that eco-design principles align with local and national environmental standards while still supporting speed-to-market and competitive pricing.

Understanding State-Level Regulatory Dynamics

Each state presents its own landscape of sustainability laws and incentives. In California, extended producer responsibility programs require manufacturers to manage end-of-life recovery. Texas emphasizes efficient manufacturing systems and energy-conscious production, while Florida and Georgia promote recycling and renewable material use through tax incentives and grants.

GID Company aligns circular economy product design strategies with these variations. We create frameworks that satisfy local compliance while optimizing the product’s sustainable product lifecycle. This ensures that design and manufacturing processes remain flexible, efficient, and regionally compliant.

Compliance by Design

Regulatory compliance doesn’t have to be reactive. GID Company practices compliance by design—embedding standards and certification requirements into every engineering phase. Our teams evaluate materials, assembly methods, and product documentation to ensure every component meets sustainability benchmarks.

By doing so, we enable clients to achieve regulatory assurance from the start rather than facing costly redesigns later. Closed-loop product design supports this readiness by ensuring that materials are traceable, recyclable, and compliant with environmental safety guidelines.

Leveraging Incentives for Sustainable Growth

Several states, including Utah and Arizona, provide grants and credits for companies investing in sustainability initiatives. GID Company helps clients identify and qualify for these programs, ensuring that their investments in circular product innovation yield financial benefits alongside environmental ones.

This alignment of regulation, design, and business opportunity transforms sustainability into a growth engine. With a clear understanding of state-specific frameworks, GID Company ensures every product supports both compliance and competitive differentiation in the marketplace.

Data, KPIs, and Business Cases for Circular Wins

Circular economy product design thrives on data. To build an efficient and measurable sustainability strategy, companies need clear performance indicators and actionable insights. GID Company turns data into direction, helping organizations measure, manage, and optimize their sustainable product lifecycle through metrics that matter.

By tracking energy efficiency, material recovery, and refurbishment rates, our clients gain a transparent view of how circular systems create economic and environmental value. This clarity turns sustainability into a predictable and scalable business advantage.

Building a Measurement Framework

A strong framework starts with measurable goals. GID Company defines key performance indicators tailored to each client’s production model. Metrics include material recovery percentage, carbon reduction, cost savings from reuse, and time-to-refurbishment cycles.

These data points provide the foundation for assessing circular product innovation performance and proving return on investment. When combined with lifecycle analysis tools, they reveal how eco-design principles directly translate into cost efficiency and lower emissions.

Tracking the Flow of Value

Data enables visibility throughout the entire closed-loop product design. By integrating digital product passports and IoT systems, GID Company helps clients track components from production to recovery. This transparency identifies inefficiencies and opportunities for process optimization.

Over time, data trends highlight how a sustainable product lifecycle reduces resource dependency and improves long-term profitability. Companies can compare multiple product lines, measure recovery success, and make data-backed decisions for future designs.

Presenting the Business Case

Circular systems make financial sense when backed by solid evidence. GID Company compiles lifecycle data into business cases that demonstrate measurable ROI. These cases quantify savings from material recovery, refurbishment, and extended product longevity.

When presented to stakeholders, the financial argument for circular economy product design becomes undeniable. Not only does it cut costs, but it also enhances brand value and aligns with investor expectations for sustainable growth.

Turning Insight into Action

Collecting data is only the beginning. GID Company works with clients to convert insights into improvements. Design teams use performance analytics to refine materials, assembly, and logistics strategies. Each iteration builds on the previous one, creating a feedback loop that fuels continuous circular product innovation.

This iterative process ensures that every design decision strengthens both financial performance and environmental outcomes—proving that sustainability, when measured effectively, is a competitive advantage.

How GID Company Works With You (California • Florida • Utah • Texas • Arizona • Georgia)

Partnering with GID Company means gaining a comprehensive approach to circular economy product design that integrates strategy, engineering, and scalability. We collaborate closely with clients across multiple industries, helping them design systems that regenerate resources, reduce waste, and maximize profit over time.

Our regional expertise ensures that every project aligns with the regulatory and logistical realities of its location, supporting a sustainable product lifecycle that’s both practical and profitable.

Discovery and Strategy Development

The journey begins with a discovery phase, where GID Company evaluates a product’s current lifecycle and identifies opportunities for improvement. Using lifecycle assessments, we map out environmental and financial hotspots to create a roadmap toward a more efficient and sustainable product lifecycle.

This strategy defines where circular value can be captured—whether through design updates, material substitutions, or reverse logistics enhancements. These insights form the foundation for long-term circular product innovation.

Design and Engineering Execution

In this stage, we turn strategy into tangible solutions. GID Company’s engineering teams apply eco-design principles to every product concept. We optimize for durability, modularity, and ease of recycling, ensuring every component supports closed-loop product design goals.

Our engineers use advanced modeling and simulation to validate each decision, confirming that the final product meets sustainability standards without compromising performance or manufacturability. Through this method, circular economy product design becomes both creative and technically precise.

Pilot Testing and Regional Scaling

Once designs are validated, GID Company launches regional pilot programs across California, Texas, and Georgia to test the full product lifecycle in real-world conditions. These pilots measure recovery rates, customer feedback, and logistical efficiency.

After successful validation, we scale the solution across other regions such as Florida, Utah, and Arizona, ensuring consistent performance within diverse supply chains. This approach guarantees that every sustainable product lifecycle remains optimized for local regulations and resource availability.

Continuous Optimization and Long-Term Partnership

Circular design is not static—it evolves with data, technology, and market shifts. GID Company provides ongoing support to monitor product performance and identify opportunities for enhancement. We analyze material reuse rates, repair efficiency, and lifecycle emissions to inform continuous improvement.

By combining eco-design principles, closed-loop product design methodologies, and data-driven circular product innovation, we help companies achieve lasting success. Every collaboration is built on transparency, adaptability, and measurable results.

Through regional insight and deep technical expertise, GID Company enables businesses to thrive within the modern sustainability landscape—proving that circular economy product design is not just about reducing impact but about redesigning success for the next generation of industry.

Wrapping Up

Circular economy product design represents a new era of intelligent, responsible manufacturing—one where every decision creates long-term value. Across California, Florida, Utah, Texas, Arizona, and Georgia, companies are recognizing that sustainability and profitability can coexist when design and innovation align. GID Company helps businesses achieve this balance by transforming the way products are imagined, built, and recovered.

By embedding eco-design principles into engineering, we ensure every product supports a sustainable product lifecycle. Our team considers the full journey—from material sourcing to recovery—making every phase an opportunity to capture value, reduce waste, and enhance performance. This comprehensive approach to design ensures durability, modularity, and recyclability at scale.

At GID Company, we see circular product innovation not as a future vision but as a present-day necessity. By developing systems that function through closed-loop product design, we help our clients eliminate inefficiencies, improve compliance, and strengthen brand reputation. This forward-thinking framework enables businesses to design products that evolve with market needs and environmental goals.

As regulations tighten and consumer expectations grow, the companies that thrive will be those that adapt early. GID Company stands ready to guide that transition—engineering a world where products don’t just serve, but sustain. Through circular economy product design, we are building smarter systems, stronger brands, and a more resilient industrial future.