It usually starts quietly.

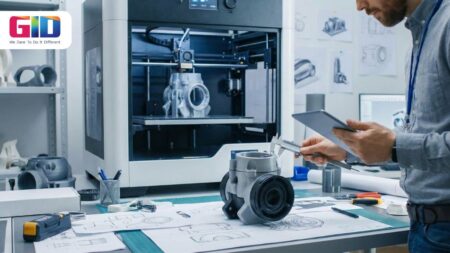

A sketch on a notepad. A 3D render on a laptop. A half-built mockup sitting on a desk in California, Texas, Florida, or somewhere in between. You know the idea has potential, but there’s a gap between imagining it and holding something real in your hands. That gap is where most inventions stall.

At GID Company, we’ve seen this moment hundreds of times. Inventors from Arizona refining hardware concepts. Founders in Utah exploring medical devices. Entrepreneurs in Georgia and Florida trying to turn rough ideas into something tangible. The uncertainty is always the same.

This guide isn’t just about what creating prototypes looks like in theory. It’s about how the process actually unfolds, step by step, and how GID Company helps inventors move forward without getting lost, overspending, or building the wrong thing.

Why Creating Prototypes Is the Turning Point

Creating prototypes is not just a technical step. It’s the emotional shift from “what if” to “this exists.”

Until a prototype is built, an invention lives in abstraction. Assumptions go untested. Risks stay hidden. Confidence remains fragile. The moment a prototype exists, the conversation changes. Suddenly, decisions are grounded in reality.

From GID Company’s perspective, creating prototypes is about clarity. It reveals what works, what doesn’t, and what needs refinement before money and time disappear into production mistakes. Whether an inventor is based in California’s tech corridors or running a startup from Texas or Florida, the prototype becomes the anchor point for everything that follows.

We don’t see prototypes as the end goal. We see them as proof that the story of the product is worth continuing.

Prototype Product Development as a Journey, Not a Task

Prototype product development isn’t a single action. It’s a sequence of deliberate steps that build on each other.

At GID Company, we frame prototype product development as a journey with three phases:

Exploration. Understanding the problem, user, and constraints.

Experimentation. Testing ideas quickly and cheaply.

Execution. Building functional prototypes that inform real decisions.

Inventors across Arizona, Georgia, and Utah often assume prototype product development starts with CAD files or fabrication. In reality, it starts with asking the right questions. What problem is this solving? Who will use it? What must the first prototype prove?

By treating prototype product development as a structured journey, GID Company helps inventors avoid the common trap of building something impressive but unusable.

Before You Create a Prototype of a Product, Clarify the Story

Before you create a prototype of a product, the story behind the invention has to be clear.

This is where many inventors struggle. The idea feels obvious in their head, but unclear to everyone else. At GID Company, we help translate that internal vision into defined requirements. What does the product absolutely need to do? What can wait? What assumptions are risky?

For inventors in California, market expectations may be speed and polish. In Florida or Georgia, durability and cost might matter more. In Utah or Arizona, regulatory or environmental factors often shape early decisions. These realities influence how you create a prototype of a product that actually makes sense.

We challenge ideas without dismissing them. That balance is critical. A prototype should express the vision, not dilute it.

Creating Prototypes on Paper Before Building Anything

One of the least understood parts of creating prototypes is how much happens before anything physical is built.

Early-stage creating prototypes often means sketches, diagrams, workflows, and rough digital models. These low-fidelity tools surface problems early, when they’re easy to fix. At GID Company, we guide inventors through this phase intentionally, knowing it saves time and money later.

This stage allows inventors in Texas or Arizona to explore multiple paths without committing to expensive fabrication. It’s where trade-offs become visible. It’s also where bad ideas quietly disappear before they become costly mistakes.

Creating prototypes doesn’t always start with machines. It starts with thinking.

Getting a Prototype Made Without Losing Control

Eventually, the question becomes unavoidable: how do you move from concept to something real?

Getting a prototype made is where many inventors feel overwhelmed. Materials, processes, timelines, and costs suddenly matter. At GID Company, we help clients understand what level of prototype they actually need. Not every invention requires a fully functional build at the start.

For some, getting a prototype made means a 3D-printed enclosure. For others, it’s a partially functional assembly designed to test a specific mechanism. The right choice depends on the goal of that prototype.

Inventors in Florida and Georgia often worry about overspending early. Founders in California and Texas worry about speed. Our role is to balance both by aligning the prototype with its purpose.

Getting a prototype made should feel controlled, not chaotic.

Companies That Make Prototypes for Inventions: Choosing Wisely

There are many companies that make prototypes for inventions, but not all of them serve inventors well.

Some companies that make prototypes for inventions focus only on fabrication. Others handle design but ignore manufacturability. The risk is building something impressive that can’t move forward.

GID Company takes a different approach. We design prototypes with the next step in mind. Even at the earliest stages, we consider how materials, processes, and assembly might scale later. This perspective matters whether an inventor is in Utah, Arizona, or Georgia.

Choosing among companies that make prototypes for inventions isn’t about finding the cheapest option. It’s about finding a partner that understands where prototypes fit in the larger product journey.

Iteration Is Where Prototype Product Development Comes Alive

The first prototype is rarely the last.

Prototype product development thrives on iteration. Each version reveals insights that weren’t obvious before. At GID Company, we help inventors interpret feedback instead of reacting emotionally to it.

Testing might happen in controlled environments or real-world settings. A prototype tested in Texas heat may behave differently than one tested indoors in California. These realities inform design changes that matter.

Iteration isn’t failure. It’s momentum. And prototype product development only works when iteration is expected, planned, and guided.

From Prototype to Production, Without a Hard Reset

One of the biggest mistakes inventors make is treating prototypes as disposable experiments with no connection to production.

At GID Company, creating prototypes always includes thinking ahead. Even early prototypes are designed with manufacturing considerations in mind. This doesn’t mean over-engineering. It means avoiding dead ends.

Regional manufacturing options vary. California offers speed and innovation. Texas and Georgia offer scaling advantages. Florida and Arizona bring unique logistical benefits. Understanding these differences early shapes smarter prototypes.

When the time comes to move forward, the transition feels natural instead of overwhelming.

How GID Company Supports Inventors Nationwide

GID Company works with inventors across California, Florida, Texas, Utah, Arizona, and Georgia. Location doesn’t limit collaboration. Clear communication and structured processes matter more than proximity.

We guide inventors through creating prototypes with transparency. We explain trade-offs. We flag risks early. Sometimes, we even recommend waiting before building. That honesty protects ideas and budgets.

Our role isn’t to push prototypes forward at all costs. It’s to help inventors make informed decisions at every step.

Wrapping Up – Holding the First Real Version

There’s a moment every inventor remembers. The first time they hold their prototype and realize it’s no longer just an idea.

Creating prototypes isn’t about perfection. It’s about progress. It’s about learning faster than uncertainty can stop you. Whether you’re building in California, refining in Texas, or testing in Florida or Georgia, the process is the same at its core.

GID Company exists to walk that path with inventors. Not as observers. Not as vendors. But as partners who understand what it takes to turn ideas into real, buildable products.