The prototype sat on the table, powered on, responsive, and impressive at first glance.

Everyone in the room could feel it—that quiet pressure-filled moment when a product looks finished, yet no one is fully confident it’s ready.

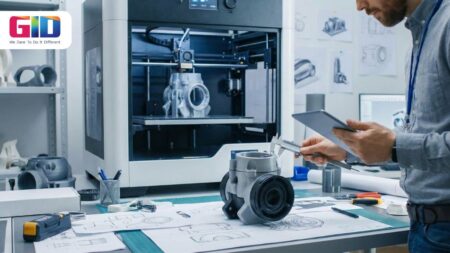

We see this moment all the time at GID Company. From early-stage teams in California to scaling manufacturers across Texas, Florida, Arizona, Utah, and Georgia, the story is always the same. The design feels complete, timelines are tight, and expectations are high. But one critical question remains unanswered—has thorough design verification testing confirmed that this product actually meets every requirement it was designed to satisfy?

That question is where disciplined testing separates successful launches from expensive lessons.

This is why we don’t treat testing as a checkbox. We treat it as a decision-making tool—one that protects your product, your budget, and your reputation.

Design Verification Testing: The Gate Between “Looks Ready” and “Is Ready”

Design verification testing exists to answer a very specific question: Did we build the product exactly as the design requirements defined?

It’s not about opinions. It’s not about excitement. It’s about evidence.

At GID Company, we see design verification testing as the last controlled checkpoint before real financial risk enters the picture—tooling investments, supplier commitments, pilot builds, and production schedules. Skipping or rushing this step often leads to late-stage redesigns that cost far more than the testing ever would have.

From rugged products built for Arizona heat to electronics intended for Florida humidity, verification ensures the design performs exactly as documented—before the market gets a vote.

Our role is to help teams enter this phase prepared, not reactive.

Design Validation and Verification: Two Different Jobs, One Shared Goal

This is where many product teams feel things start to blur.

Design validation and verification may sound similar, but they serve different purposes—and confusing them can derail development fast.

Verification confirms the design meets written requirements. Validation confirms the product solves the user’s real-world problem. One is design-focused. The other is user-focused.

At GID Company, we help teams clearly separate these phases while keeping them strategically aligned. When teams attempt to validate before verification is complete, results become unreliable. When verification ignores downstream use cases, validation becomes painful.

We help structure both so they reinforce each other instead of competing for time and budget.

Read More: Additive Manufacturing Benefits for U.S. Product Development

Difference Between Design Verification and Design Validation (Without the Guesswork)

Understanding the difference between design verification and design validation removes a surprising amount of stress from product development.

Verification asks:

Does the product meet defined specifications under controlled conditions?

Validation asks:

Does the product succeed in real environments with real users?

These questions matter even more when products are deployed across different regions. A product validated in California office environments may behave very differently on job sites in Texas or outdoor installations in Utah.

GID Company ensures verification evidence stays measurable and requirement-driven, while validation remains grounded in realistic use conditions—without crossing wires between the two.

Design Verification Test Plan: The Difference Between Control and Chaos

A solid design verification test plan prevents what we often call “testing by panic.”

Without a plan, teams test whatever feels urgent. With a plan, teams test what actually matters.

At GID Company, we build verification plans that include:

- Clear traceability between requirements and tests

- Defined acceptance criteria—no subjective pass/fail calls

- Appropriate sample sizes for confidence, not guesswork

- Test methods that match real risks, not assumptions

- Documentation structured for internal and external review

This becomes especially critical when coordinating across regions—engineering in California, manufacturing partners in Georgia or Texas, and suppliers elsewhere. A clear plan keeps everyone aligned.

Design Validation Test: Proving the Product Works Where It Counts

A design validation test shifts the spotlight from requirements to reality.

This is where products encounter real users, real workflows, and real constraints. Validation isn’t about lab perfection—it’s about practical success.

At GID Company, we help teams design validation efforts that reflect how products will actually be used. That may mean accounting for environmental exposure in Arizona, handling conditions in Florida, or operational variability across distributed teams in the South.

Validation doesn’t need to be flashy. It needs to be honest. We focus on learning without overcomplicating the process or delaying launch decisions.

How GID Company Guides Verification Without Slowing You Down

This is where the story turns.

That tense “almost-ready” moment doesn’t have to end in delays or redesigns. With the right structure, it becomes a point of confidence.

GID Company supports design verification testing by:

- Refining requirements before testing begins

- Prioritizing risks that could impact launch success

- Aligning verification timing with supplier realities

- Packaging test evidence for stakeholder approval

- Creating a smooth handoff into validation and production

Whether teams are building locally in California or coordinating production across Texas, Arizona, Utah, Florida, and Georgia, our approach keeps momentum intact while reducing surprises.

Wrapping Up

Products don’t fail because teams lack talent. They fail when uncertainty is allowed to survive too long.

Design verification testing turns uncertainty into clarity. It transforms “we think it works” into “we know it works.”

At GID Company, we help product teams move forward with confidence—by building verification and validation strategies that protect schedules, budgets, and outcomes long before launch day arrives.