Digital twins are transforming how products are designed, tested, and refined across the U.S., and GID Company is at the forefront of this change. From concept visualization to performance optimization, this technology is revolutionizing how we bring ideas to life faster and smarter.

Across California, Texas, Florida, Utah, Arizona, and Georgia, industries are embracing this shift to create products that are not only more efficient but also more sustainable. The ability to simulate and optimize in a virtual environment gives engineers the insight to eliminate errors before they happen, saving both time and cost.

At GID Company, we don’t just implement digital twin technology—we make it practical and impactful. By integrating data, modeling, and analytics, our experts ensure every product we help design performs exactly as envisioned. This is more than a digital upgrade; it’s the future of design made real through innovation and precision.

Digital Twins: The Backbone of Modern Product Design

Digital twins are no longer experimental—they’re a foundational part of modern engineering and product innovation. By bridging the digital and physical worlds, they allow manufacturers to create precise virtual counterparts of their real-world systems. GID Company utilizes this approach to help clients reduce uncertainty and accelerate decision-making throughout the design cycle.

How Digital Twins Streamline the Design Cycle

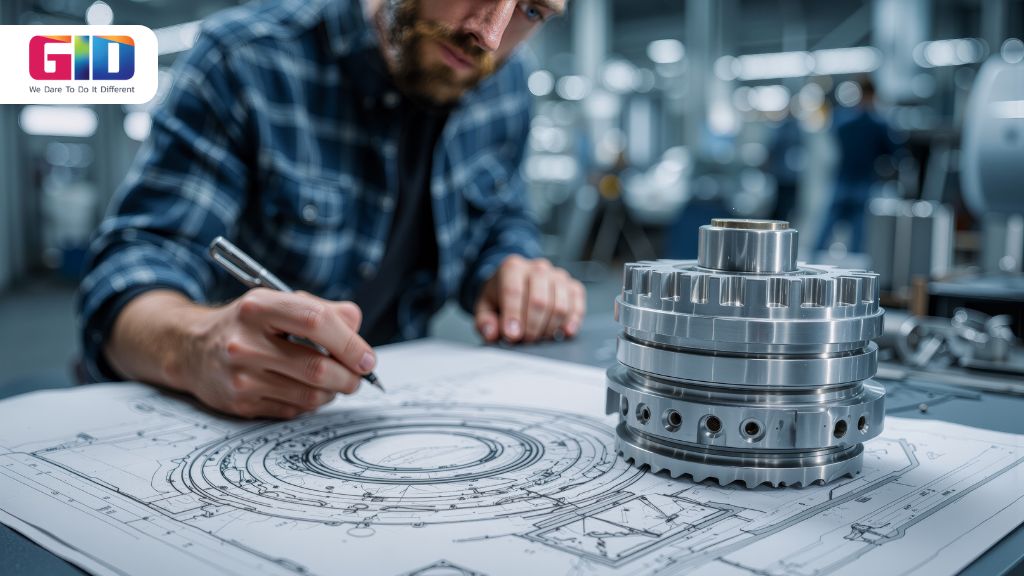

Designing a product traditionally involves guesswork and multiple prototype iterations. With digital twin technology, GID Company helps eliminate those inefficiencies by creating a fully interactive digital environment. Engineers can run experiments virtually, tweak specifications, and simulate performance under different conditions—all before a single prototype is built.

This virtual approach drastically shortens development timelines and improves design accuracy. It also allows teams to identify performance gaps early, enabling smarter refinements that lead to better final products. By adopting digital twins, companies in California, Florida, and Texas are improving design outcomes and reducing manufacturing risks simultaneously.

The Power of Smart Product Simulation

The true strength of digital twins lies in their ability to learn and evolve using real-time data. Through smart product simulation, GID Company integrates physical parameters and operational feedback into virtual models, ensuring continuous improvement and reliability.

By analyzing behavior under stress, temperature, and environmental shifts, we help businesses anticipate real-world challenges. This process ensures each design iteration is better than the last—boosting performance and extending product lifespan. Whether developing industrial systems in Georgia or consumer products in Utah, our smart product simulation strategy delivers consistency and confidence.

Expanding Capabilities with Virtual Product Modeling

Virtual product modeling is where creativity meets precision. It allows GID Company engineers to visualize every dimension, material, and motion within a digital framework. This clarity helps teams collaborate seamlessly and spot design conflicts long before production begins.

For clients across Arizona and beyond, virtual modeling provides the flexibility to innovate without risk. When combined with digital twin applications, it becomes a living design system that adapts and evolves as data accumulates. This approach transforms every phase of product development—from early concept sketches to mass-scale manufacturing validation.

Practical Impact of Digital Twin Applications

Digital twin applications are reshaping how companies operate across multiple industries. At GID Company, we help clients implement these solutions strategically—whether it’s improving product quality, reducing waste, or optimizing assembly efficiency.

By connecting design and production data, teams can monitor, predict, and fine-tune performance continuously. The result is a feedback-driven cycle that enhances every subsequent release. Across Utah, Georgia, and other innovation hubs, digital twin applications are unlocking faster go-to-market strategies and enabling smarter, more sustainable production models.

Shaping the Future of Product Innovation

Digital twins represent far more than a technological trend—they’re the future of intelligent product design. GID Company’s integrated framework blends digital twin technology, virtual product modeling, and smart product simulation into one cohesive ecosystem.

This enables U.S. businesses to design confidently, manufacture efficiently, and adapt rapidly. As we continue to support innovation across states like California and Texas, GID Company remains committed to delivering results that push the boundaries of what’s possible in modern product engineering.

Understanding Digital Twin Technology (Stack, Data, and Operations)

Digital twin technology serves as the engine behind the growing influence of digital twins across U.S. manufacturing and product innovation. By combining data connectivity, artificial intelligence, and advanced modeling, GID Company helps businesses create a continuous feedback loop between real and virtual environments. This integration allows design teams to make confident decisions faster and adapt more effectively to market changes.

Building the Core Architecture

At the foundation of every digital twin technology system lies a powerful combination of sensors, data pipelines, and intelligent models. These elements collect and interpret information about a product’s behavior, structure, and environmental interactions. GID Company designs these systems to function seamlessly, ensuring that virtual models stay synchronized with physical assets in real time.

This architecture transforms how teams approach design. Instead of waiting for physical tests, engineers can validate decisions using accurate simulations and predictive algorithms. Across California, Texas, and Georgia, our implementations enable companies to eliminate guesswork and build stronger, smarter products from day one.

Data Integration and Real-Time Feedback

The strength of digital twins comes from their ability to turn raw data into actionable insight. At GID Company, we build digital ecosystems that connect production lines, sensors, and simulation platforms into a unified structure. This integration ensures that real-time performance data continuously updates the virtual counterpart.

Through this process, digital twin technology becomes a living, evolving model—one that not only reflects current performance but also predicts what’s next. Whether a product operates in the heat of Arizona or the humidity of Florida, these live feedback loops help teams detect anomalies, optimize maintenance schedules, and extend product lifespan.

Enhancing Collaboration and Innovation

When teams have a shared digital environment, creativity and collaboration reach new heights. GID Company leverages digital twins to bring together design engineers, analysts, and production specialists under a single source of truth. This shared model eliminates data silos and ensures everyone works from the same accurate foundation.

In industries across Utah and Georgia, this collaborative environment reduces rework, accelerates development, and promotes innovation. By maintaining synchronized updates across every department, our digital twin technology empowers companies to align strategy, execution, and quality assurance under one connected framework.

Virtual Product Modeling: From Idea to Validated Design

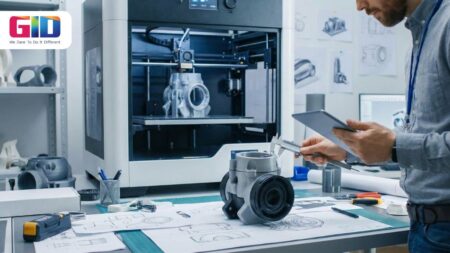

Virtual product modeling is the creative bridge that turns ideas into detailed digital representations ready for validation. As part of a larger digital twins strategy, it allows engineers to visualize, simulate, and optimize every aspect of a product before physical production begins. GID Company uses this approach to enhance precision, shorten development cycles, and reduce cost across diverse industries throughout the United States.

Designing with Accuracy and Agility

In traditional design processes, teams often face uncertainty when predicting how products will behave under real-world conditions. With virtual product modeling, GID Company eliminates that uncertainty. By simulating geometry, material behavior, and structural response, our engineers can refine each feature until it meets exact performance targets.

This approach ensures every prototype is data-driven and purpose-built. Whether developing consumer electronics in California or industrial tools in Texas, companies gain the confidence that each iteration is optimized long before the first physical prototype is made. Virtual product modeling makes innovation not only faster but far more reliable.

Integrating Smart Product Simulation

When virtual models are combined with smart product simulation, they evolve from static blueprints into dynamic, predictive systems. GID Company merges these capabilities within our design workflows, enabling real-time scenario testing and system optimization.

This integration allows engineers to test how different materials respond to stress, temperature, and motion without ever leaving the digital environment. As a result, manufacturers in Utah and Florida can discover flaws early, make informed changes instantly, and avoid costly delays. Smart product simulation transforms every decision into an evidence-backed improvement, leading to higher efficiency and stronger end products.

Applying Digital Twin Applications for Continuous Improvement

Digital twin applications turn modeling and simulation into an ongoing cycle of learning. GID Company implements these applications to ensure that every product benefits from continuous optimization even after launch. Data collected from field performance feeds back into the virtual model, allowing teams to identify trends and enhance designs over time.

For companies in Georgia, Arizona, and beyond, this creates a lasting advantage. Each new design iteration builds upon verified insights from previous versions, improving durability, sustainability, and customer satisfaction. By combining digital twin applications with advanced modeling and simulation, GID Company delivers a fully integrated digital ecosystem built for perpetual innovation.

The GID Company Edge in Virtual Design

Virtual product modeling powered by digital twins is not merely a design enhancement—it’s a competitive advantage. GID Company’s approach unites every digital layer, from concept modeling to lifecycle analysis, in a way that’s tailored to each client’s operational goals.

Our solutions enable businesses across the U.S. to innovate boldly and produce confidently, knowing every product has been tested, refined, and optimized through digital twin technology and smart product simulation. With this data-driven design foundation, GID Company continues to shape the future of intelligent product engineering—one virtual prototype at a time.

Smart Product Simulation for Faster, Safer Iteration

Smart product simulation is one of the most powerful applications of digital twins in modern design and manufacturing. It allows engineering teams to model real-world physics, materials, and environmental conditions in a risk-free digital space. At GID Company, this approach enables faster product iteration, better quality control, and significant cost reduction across industries in California, Texas, and Florida.

Redefining Product Validation Through Simulation

Traditional validation relies on multiple physical prototypes that consume time and resources. Through smart product simulation, GID Company replicates product behavior in virtual form, allowing designers to test multiple conditions simultaneously. This method ensures that every product iteration meets reliability and performance goals long before physical testing begins.

By leveraging the precision of digital twin technology, GID Company helps clients predict potential design flaws and correct them early. The insights derived from simulation analytics reduce uncertainty and provide confidence in every engineering decision. Companies across Utah and Arizona are using this approach to achieve safer and more consistent product performance while accelerating time to market.

Merging Data and Physics for Realistic Testing

The true potential of digital twins comes to life when data and physics-based models converge. GID Company builds this connection by combining operational data with simulated environments to generate a complete product perspective. Each virtual model mirrors its real-world counterpart, allowing precise observation of how different variables influence performance.

This integration enables ongoing refinement through virtual product modeling and real-time updates. As products evolve, digital twin applications feed live performance data back into the simulation framework, creating a continuous improvement cycle. The result is a design process that never stands still—it learns, adapts, and evolves with every iteration.

Building Safer, More Reliable Products

Safety and reliability form the core of GID Company’s product development philosophy. With smart product simulation, our engineers can evaluate stress points, fatigue thresholds, and environmental impact without risking physical assets. This predictive approach minimizes the chance of failure and improves regulatory compliance across all product categories.

In states like Georgia and Florida, this process has become vital for industries that prioritize safety and precision. By using digital twin technology alongside advanced simulation methods, GID Company ensures every design achieves the highest level of performance validation before manufacturing begins.

Accelerating Innovation Cycles

Speed and accuracy define modern engineering success. By integrating smart product simulation within the framework of digital twins, GID Company drastically reduces the time between design conception and market release. Teams can run hundreds of virtual experiments simultaneously, testing variations that would otherwise take months in physical trials.

This acceleration allows businesses across California and Texas to deliver more innovative products to market without compromising quality. It also establishes a flexible foundation where continuous feedback from digital twin applications enhances each new release, ensuring designs remain aligned with evolving customer needs.

Digital Twin Applications You Can Launch This Quarter

Digital twin applications are the most practical step toward implementing a connected, intelligent design ecosystem. They translate the power of digital twins into real, measurable results across the product lifecycle. At GID Company, these applications are designed for fast deployment and immediate value realization in diverse industries throughout the United States.

Accelerating Design Validation

Digital twin applications enable real-time product validation during the earliest stages of design. GID Company implements systems that allow engineers to test functional performance under various conditions using virtual product modeling and smart product simulation. This proactive approach helps detect design flaws before production begins, saving both time and budget.

By integrating digital twin technology into everyday workflows, companies in Utah and Arizona achieve seamless transitions from concept to manufacturing. This ensures that every design iteration is guided by accurate data and predictive insights, improving overall efficiency and reducing risk throughout development.

Enhancing Predictive Maintenance and Service

Digital twins extend far beyond design—they also transform product maintenance and operation. GID Company applies digital twin applications that continuously monitor equipment health and performance. By analyzing live data streams, our systems can predict potential issues before they occur, minimizing downtime and maintenance costs.

For manufacturers in Georgia and Texas, this approach has become a critical enabler of smarter operations. Predictive analytics derived from digital twin technology allow maintenance teams to shift from reactive to preventive strategies, optimizing resource allocation and ensuring consistent product performance.

Optimizing Production and Assembly

In manufacturing, precision and speed define success. GID Company uses virtual product modeling and digital twins to optimize production lines, detect inefficiencies, and enhance throughput. Digital twin applications enable dynamic simulations of assembly workflows, allowing for rapid testing of layout changes and process adjustments.

This data-driven optimization improves productivity and reduces material waste. For businesses in California and Florida, the ability to simulate and refine processes virtually ensures greater control over manufacturing quality, resulting in fewer defects and higher customer satisfaction.

Creating Scalable Solutions for Growth

Every business seeks a foundation that scales with its growth. GID Company’s digital twin technology solutions are built to evolve alongside our clients’ needs. Whether it’s a startup designing its first product or an established manufacturer expanding across states, our digital twin applications adapt effortlessly to any complexity level.

Through smart product simulation and continuous data integration, GID Company provides scalable systems that strengthen long-term innovation. These adaptable frameworks make it easier to adopt new technologies, connect additional facilities, and maintain consistency across all operations nationwide.

Delivering Measurable ROI and Long-Term Value

Digital twin applications deliver immediate results—but their greatest benefit lies in sustained improvement. At GID Company, we focus on long-term return by embedding analytics and feedback mechanisms into every digital system we create. This continuous improvement process ensures that each design, prototype, and production cycle becomes more efficient over time.

For organizations in Utah, Arizona, and Georgia, this translates into measurable business growth. By merging virtual product modeling, smart product simulation, and real-time feedback, GID Company turns innovation into a repeatable, scalable, and profitable process powered by digital twins.

Architecture Patterns: Picking the Right Twin for Your Product

Selecting the right architecture for digital twins is a critical step in building a scalable and efficient design ecosystem. Each product requires a unique balance between data accuracy, system complexity, and real-time performance. At GID Company, our approach focuses on creating tailored frameworks that match each client’s engineering objectives, manufacturing capacity, and innovation roadmap across states like California, Texas, and Georgia.

Understanding Component, System, and Process Twins

Digital twin technology comes in multiple architectural forms—component twins, system twins, and process twins—each with its own purpose. GID Company helps organizations identify which type delivers the most value depending on their design stage and operational goals.

Component twins replicate specific product parts or subsystems. They are ideal for early testing through virtual product modeling, helping engineers refine details before full-scale assembly. System twins connect multiple components into a complete digital ecosystem, offering real-time visibility into performance across the product’s lifecycle. Process twins focus on workflows and manufacturing sequences, simulating how operations interact to improve overall efficiency.

By combining these models under a unified structure, GID Company ensures that digital twins evolve smoothly as projects grow more complex. This adaptability enables clients in Utah and Arizona to start small and scale up without reconfiguring their digital infrastructure.

Balancing Edge and Cloud for Performance

The choice between edge and cloud processing defines how effectively digital twins handle real-time data. GID Company designs hybrid architectures that balance both, optimizing responsiveness and computational efficiency. For applications requiring immediate decisions, edge computing ensures low-latency analysis right at the production site. For long-term analytics and system optimization, cloud processing provides broader computational power and centralized control.

Through this dual approach, our clients can maintain both speed and scalability. Whether a company manages an industrial facility in Georgia or a product lab in California, this architecture ensures that virtual product modeling and smart product simulation run smoothly under varying network conditions.

Ensuring Security and Data Integrity

Security is foundational to every digital system, and digital twin technology is no exception. GID Company embeds robust cybersecurity measures into every twin architecture we develop. From encrypted data exchanges to access-controlled environments, each layer protects the integrity of critical design and operational data.

This emphasis on security not only protects intellectual property but also ensures regulatory compliance across industries. Our secure frameworks enable teams to collaborate confidently, sharing virtual product modeling and simulation data without compromising confidentiality or reliability.

Integrating Digital Twin Applications into the Enterprise

Digital twin applications thrive when seamlessly connected with existing enterprise systems. GID Company specializes in integrating these solutions into established PLM, CAD, and IoT environments. This integration allows digital twins to act as a single source of truth across departments—engineering, manufacturing, and service.

In practice, this means teams across Texas, Florida, and Utah can collaborate in real time using shared, synchronized data models. With digital twin applications embedded into daily workflows, businesses gain full operational visibility, streamlined decision-making, and accelerated innovation cycles.

Roadmap & Governance: Your First 180 Days with GID Company

Launching digital twins effectively requires a clear strategy, disciplined execution, and ongoing governance. GID Company guides clients through a structured 180-day roadmap designed to establish a solid foundation for long-term success. This process ensures that each phase—from pilot setup to system scaling—is measured, predictable, and value-driven.

Phase One: Discovery and Data Readiness

The journey begins with understanding the product’s ecosystem and data maturity. GID Company works with clients to identify existing assets, data sources, and operational gaps that influence digital twin technology adoption. During this stage, our team develops a blueprint for data collection, integration, and storage that aligns with business goals.

This discovery process sets the stage for implementing virtual product modeling and smart product simulation effectively. With a clean data foundation, teams can ensure that simulations reflect accurate, real-world conditions. Companies across California and Texas often find this stage crucial for aligning digital twin strategies with existing engineering infrastructure.

Phase Two: Pilot Definition and Model Calibration

After data preparation, GID Company launches a targeted pilot focusing on a single product line or process. This phase allows teams to evaluate performance metrics and validate assumptions before scaling. Through digital twin applications, real-time feedback from simulated operations helps calibrate models for precision and reliability.

Our engineers use this phase to fine-tune virtual product modeling workflows, ensuring that models behave predictably under different conditions. As a result, clients in Georgia and Florida can measure early ROI, identify process improvements, and establish clear benchmarks for expansion.

Phase Three: Scaling and Governance Framework

Once pilot goals are achieved, the next step involves scaling digital twins across broader operations. GID Company creates governance structures that define data ownership, update protocols, and performance standards. This ensures every team—from design to manufacturing—follows consistent best practices.

Our governance models also include training sessions, documentation, and compliance reviews to maintain the integrity of digital twin technology systems. For organizations in Arizona and Utah, this structured expansion ensures scalability without losing agility or control.

Phase Four: Continuous Optimization and ROI Tracking

The final stage emphasizes sustainability and continuous improvement. GID Company integrates feedback mechanisms that monitor performance, predict maintenance needs, and identify optimization opportunities using smart product simulation.

Over time, digital twin applications evolve as products mature, ensuring that insights from each phase feed into future development cycles. This continuous learning framework transforms digital twins from one-time projects into ongoing assets that deliver measurable returns for years to come.

Building a Culture of Innovation

Beyond implementation, GID Company helps organizations build a lasting culture of digital innovation. By aligning strategy, data, and collaboration, businesses in California, Georgia, and Texas gain a sustainable advantage in product development. Digital twin technology becomes not just a tool but a central pillar of innovation strategy—empowering teams to design better, smarter, and faster.

Through this structured roadmap, GID Company ensures that the adoption of digital twins translates into tangible value. From concept to execution, every step reinforces the goal of creating products that are not only efficient and reliable but also visionary in their design and performance.

Tooling & Integration: Making It Work with Today’s Stack

The success of digital twins depends on seamless integration with existing tools and workflows. GID Company designs interoperability solutions that bridge engineering design, manufacturing systems, and data analytics to create a unified ecosystem. This approach ensures that digital twin technology works harmoniously within your current infrastructure without costly replacements or disruptions.

Connecting Core Engineering Tools

For digital twins to operate efficiently, they must integrate with platforms such as CAD, PLM, and IoT systems. GID Company builds flexible architectures that synchronize data between these platforms, allowing every model and simulation to remain consistent. Through virtual product modeling, teams gain real-time visibility into design evolution, improving collaboration and reducing redundant work.

This connectivity ensures that changes made in one system are reflected instantly across the entire network. Whether in a California aerospace lab or a Texas industrial facility, this connected approach allows engineers to maintain a single, accurate source of truth for every project.

Creating Unified Data Pipelines

Digital twin technology relies on clean, structured, and accessible data. GID Company develops unified data pipelines that collect and process information from sensors, machines, and production systems. These pipelines serve as the foundation for accurate modeling, analytics, and decision-making.

By integrating smart product simulation directly into these pipelines, our clients can visualize the immediate impact of operational changes. As data flows in, digital twin applications continuously adjust virtual representations, keeping every digital asset synchronized with its physical counterpart. This live synchronization helps teams in Arizona and Utah identify issues early, refine processes, and boost production efficiency.

Streamlining Workflows Through Automation

Automation ensures that digital twins operate without manual intervention. GID Company introduces workflow automation across design, validation, and maintenance processes, enabling teams to focus on innovation rather than repetitive tasks.

For instance, updates in virtual product modeling automatically trigger recalculations in simulations, keeping results current and accurate. This fluid interaction between systems enhances productivity and helps manufacturers in Georgia and Florida achieve consistent quality control. Through automation, digital twin technology becomes a self-sustaining system that continually improves performance across all operations.

Cost, ROI, and Risk Management

Implementing digital twins is an investment that yields measurable returns through efficiency, accuracy, and longevity. GID Company focuses on maximizing ROI while managing associated costs and risks. By combining digital twin technology, virtual product modeling, and smart product simulation, we help clients balance innovation with financial responsibility.

Understanding the Cost Structure

The cost of implementing digital twins varies based on project complexity, data availability, and integration needs. GID Company provides transparent frameworks that map investment to value at every stage of deployment. This clarity helps clients make informed budgeting decisions while planning for long-term scalability.

Initial expenses often cover model creation, data preparation, and digital twin applications. However, these investments quickly pay off through reduced physical prototyping and fewer production errors. For businesses in California and Texas, the resulting time savings and improved reliability far outweigh initial setup costs.

Calculating Tangible ROI

The benefits of digital twins extend across the product lifecycle—from concept to service. GID Company measures ROI in terms of faster development cycles, improved product performance, and reduced downtime. Using smart product simulation, teams can identify inefficiencies early, leading to substantial cost avoidance.

Moreover, virtual product modeling allows multiple design variations to be tested simultaneously, eliminating waste and accelerating time to market. Companies across Utah and Georgia report improved profit margins as digital twin technology continues to refine products and processes long after initial deployment.

Minimizing Risk Through Predictive Insight

Risk management is central to every GID Company engagement. With digital twin applications, we help businesses predict potential failures and simulate recovery strategies before issues escalate. By combining data-driven forecasting with accurate virtual modeling, our teams mitigate both design and operational risks.

This predictive approach is particularly valuable for industries operating in demanding environments, such as manufacturing in Arizona or transportation systems in Florida. By running simulations under different conditions, companies can confidently design resilient systems that withstand real-world challenges. Through smart product simulation, GID Company ensures that safety and performance remain at the forefront of every innovation.

Talent & Change: Upskilling Your Team

The adoption of digital twins is as much about people as it is about technology. To make full use of digital twin technology, organizations must equip their teams with new skills, processes, and mindsets. GID Company supports this transformation through targeted training, guided implementation, and long-term enablement strategies across California, Georgia, and Texas.

Building Digital Literacy

Understanding how digital twins function is the first step toward effective adoption. GID Company conducts workshops and on-the-job training sessions that cover data management, simulation techniques, and model validation. By exposing teams to the principles of virtual product modeling, employees learn how to interpret simulation outcomes and make data-backed design decisions.

This hands-on learning builds confidence and ensures every engineer or designer can contribute meaningfully to the digital workflow. In regions like Utah and Arizona, where high-tech manufacturing continues to expand, developing this literacy gives companies a distinct advantage in attracting and retaining skilled talent.

Developing New Roles and Collaboration Models

As digital twin technology becomes embedded across departments, new roles and workflows naturally emerge. GID Company helps businesses redefine job functions, creating synergy between engineering, data science, and production teams.

With smart product simulation integrated into everyday operations, data analysts and mechanical engineers collaborate more effectively, each drawing insights from shared models. This cross-functional environment eliminates silos and speeds up design validation. Digital twin applications also promote transparency, allowing everyone—from project leads to maintenance crews—to work from a unified information source.

Establishing Continuous Learning Frameworks

Innovation doesn’t stop once digital twins are deployed. GID Company partners with clients to establish ongoing learning programs that evolve alongside technology. These frameworks include continuous certification, new simulation tool training, and model governance refreshers.

In Florida and California, this commitment to skill growth ensures that companies remain agile as their systems mature. Teams not only keep pace with emerging technologies but also drive innovation from within. Through ongoing exposure to virtual product modeling and smart product simulation, employees become confident leaders in digital transformation.

Building a Culture of Change and Ownership

At the heart of GID Company’s approach lies the belief that people drive progress. Our change management programs help organizations cultivate a culture that embraces digital transformation. By aligning training, communication, and leadership engagement, we ensure that digital twin technology adoption becomes a shared mission rather than a top-down directive.

From the factory floor in Georgia to R&D centers in Texas, employees learn to take ownership of innovation. This mindset shift ensures that digital twins remain an active part of daily operations, fueling creativity, improving collaboration, and sustaining long-term competitive advantage.

Wrapping Up

Digital twins are reshaping how businesses design, test, and evolve their products, turning data into a driver of real-world innovation. Across the United States, GID Company continues to lead this transformation by combining creativity with engineering precision. Through the strategic use of digital twin technology, virtual product modeling, smart product simulation, and digital twin applications, we help companies accelerate innovation while reducing cost and risk.

Driving Smarter Design Across the U.S.

From California to Georgia, businesses are leveraging digital twins to close the gap between digital vision and physical reality. GID Company empowers organizations to design faster, validate more accurately, and adapt to change confidently. Our solutions integrate seamlessly into existing systems, offering real-time insights that improve every stage of product development.

By merging smart product simulation and virtual product modeling into a unified workflow, we enable engineering teams to detect potential design challenges before production even begins. This proactive approach ensures consistent quality, sustainable innovation, and reduced time to market for every product we help bring to life.

Building Long-Term Innovation Value

The power of digital twin technology lies in its adaptability and scalability. GID Company develops systems that evolve alongside each client’s business needs. Whether improving product durability or optimizing assembly performance, our digital twin applications ensure continuous improvement through ongoing data feedback.

Organizations across Texas, Utah, Arizona, and Florida are now seeing firsthand how digital twins enable better forecasting, stronger performance monitoring, and smarter resource utilization. By fostering collaboration across departments, GID Company helps turn every engineering challenge into an opportunity for innovation.

Partnering for the Future

Innovation is not a single project—it’s a mindset. GID Company partners with businesses ready to embrace this future through transformative design methods powered by digital twins. Our approach unites advanced simulation, predictive analytics, and practical engineering insight to ensure every product performs at its best.

As industries evolve, GID Company remains committed to guiding companies toward a smarter, more connected future. With our expertise in digital twin technology, virtual product modeling, and smart product simulation, the path to intelligent design has never been clearer—or more achievable.