Eco friendly materials are at the core of modern, responsible product development. At GID Company, we understand that material selection isn’t just a technical decision—it’s a reflection of brand values, environmental accountability, and long-term product viability. Whether you’re based in California, Texas, Florida, Georgia, Arizona, or Utah, the market’s demand for sustainability is growing louder by the day.

Consumers are no longer passive buyers. They’re active participants in sustainability, seeking products that reflect conscious manufacturing choices. For companies aiming to stay relevant and responsible, incorporating eco friendly materials into product design is no longer optional—it’s a strategic necessity. That’s where GID Company steps in.

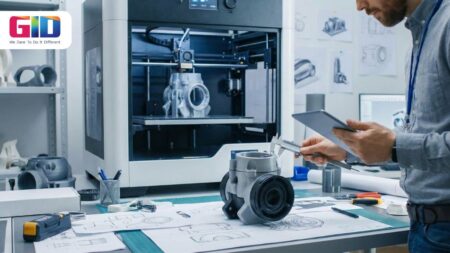

As a full-service product development firm, we specialize in helping businesses integrate eco-friendly product materials into their design process from concept to commercialization. We don’t just consult—we build, test, and launch real-world solutions that work within your budget, supply chain, and environmental goals. In this article, we explore how sustainable raw materials and smart material selection are transforming product development—and how GID Company can be your partner in navigating that shift.

Why Eco Friendly Materials Matter in Product Design

Choosing eco friendly materials isn’t a design trend. It’s a foundational shift in how companies approach product development. From regulatory compliance to consumer demand, the pressure to rethink material choices is shaping product strategies across industries.

What Defines Eco Friendly Materials

Eco friendly materials are defined by their reduced environmental impact over their full life cycle. This includes how they are sourced, processed, used, and disposed of. These materials are typically non-toxic, low-emission, and either biodegradable, recyclable, or sustainably harvested. For businesses working with GID Company, selecting these materials means optimizing not just for environmental performance, but also for manufacturing compatibility and durability.

From biodegradable materials for products that break down naturally, to recycled materials for product design that close the loop on waste, the choices are diverse—but must be carefully evaluated. Our team helps clients find the right material balance without sacrificing performance.

Market and Regulatory Drivers

Government regulations in regions like California and Florida are tightening around environmental compliance. Companies can no longer afford to overlook material origin, recyclability, or environmental toxicity. Meanwhile, consumers in Texas, Georgia, and Arizona are aligning with brands that actively pursue sustainability through their material decisions.

At GID Company, we support our clients with in-depth knowledge of these evolving regulations and help them future-proof their designs. Integrating eco friendly materials from the start ensures your product not only meets today’s expectations but adapts to tomorrow’s compliance standards.

Environmental and Social Impact

Using eco friendly materials and eco-friendly product materials isn’t just about environmental performance; it’s also about brand positioning. Consumers trust brands that demonstrate transparency and accountability. Products made with sustainable raw materials send a powerful message—your brand cares.

When companies collaborate with GID Company, we evaluate material choices through a multi-lens approach: environmental impact, consumer perception, and commercial viability. Whether the product uses biodegradable materials for products or relies on a blend of recycled and sustainable components, we ensure the final outcome reflects your brand’s commitment to sustainability.

Design Considerations and Trade-Offs

Adopting eco friendly materials does introduce new design challenges—structural strength, durability, and availability being top considerations. Not all materials labeled as “green” perform equally across applications. That’s why GID Company applies rigorous material vetting, testing, and prototyping before final integration.

We help you navigate decisions such as when to use recycled materials for product design versus sourcing plant-based options. Each project has unique constraints, and our team ensures those constraints are matched with materials that meet your functional, aesthetic, and environmental goals.

Regional Context: Why Local Sourcing Matters

In states like Utah and Arizona, proximity to raw materials can reduce carbon emissions and lead times. GID Company leverages its regional knowledge to source eco friendly materials and eco-friendly product materials as close to the point of manufacture as possible. This not only reduces environmental impact but also cuts down costs and streamlines production schedules.

From sustainable raw materials harvested responsibly to engineered materials made from post-consumer waste, we align your product vision with locally accessible solutions. Our experience in regional sourcing allows us to develop efficient and environmentally smart supply chains for every product we touch.

Exploring Biodegradable Materials for Products

Biodegradable materials for products are gaining traction across industries due to their ability to reduce environmental harm without compromising on functionality. As part of the broader push toward eco friendly materials, these options naturally break down through microbial activity, leaving minimal to no harmful residue. At GID Company, we help businesses identify and integrate the right biodegradable alternatives into their designs to align with both sustainability goals and consumer expectations.

Natural Polymers and Bioplastics

Natural polymers and bioplastics are some of the most versatile biodegradable materials for products. Derived from renewable sources like corn starch, sugarcane, and potato starch, these materials can mimic the mechanical properties of traditional plastics while offering a significantly lower ecological footprint. When designed correctly, bioplastics can become effective eco friendly materials in product development, especially for short lifecycle consumer goods.

GID Company works closely with manufacturers to determine which biopolymers are best suited for specific applications. From disposable packaging components to more durable parts for consumer electronics, we ensure these eco-friendly product materials meet your product’s performance and aesthetic requirements.

Plant-Based Fibers and Bio-Composites

Plant-based fibers, such as hemp, jute, flax, and bamboo, are widely used in creating lightweight, strong, and biodegradable components. When combined with other sustainable raw materials like natural resins, they form bio-composites that are ideal for modern product design. These combinations are not only biodegradable but also renewable, making them strong contenders among eco friendly materials.

At GID Company, we evaluate these natural materials not just on their environmental benefits, but also on how well they integrate with our clients’ production processes. Whether used in structural components or decorative finishes, plant-based fibers provide a unique aesthetic while maintaining eco-conscious integrity.

Mushroom and Algae-Based Materials

Innovative solutions like mycelium (mushroom root systems) and algae-based materials are redefining the limits of sustainable product design and expanding the scope of eco friendly materials. These organic substances grow quickly and can be molded into shapes, dried, and used as biodegradable materials for products with excellent insulation, cushioning, or lightweight structural needs.

For clients in regions like California or Florida, where green innovation is a priority, GID Company supports the prototyping and scaling of these advanced bio-materials. Our team ensures that these components not only perform well but also comply with regional environmental standards, making them valid options for future-ready eco-friendly product materials.

Agricultural Waste and Upcycled Plant Matter

Materials derived from agricultural waste—such as bagasse from sugarcane, rice husks, or coconut coir—are both biodegradable and economically efficient. These options are perfect for brands aiming to combine eco friendly materials with cost-conscious manufacturing. By diverting waste from landfills and reintroducing it into the supply chain, these inputs qualify as both biodegradable materials for products and recycled materials for product design when processed appropriately.

GID Company explores these sources for clients across states like Texas and Georgia, where agricultural byproducts are readily available. We evaluate availability, supply chain stability, and design feasibility to ensure the material matches the product’s needs while fulfilling environmental objectives.

Design and Performance Considerations

While the environmental advantages of biodegradable materials are clear, their use in product design—especially as eco friendly materials—requires careful attention to performance factors such as durability, moisture resistance, and shelf life. Not all biodegradable components perform equally, and inappropriate use can lead to premature product failure or limited market acceptance.

At GID Company, we conduct rigorous testing on all proposed biodegradable and eco-friendly product materials to ensure they align with the product’s usage lifecycle. We balance environmental performance with commercial practicality, giving our clients the confidence that their products won’t just be sustainable—they’ll be successful in the market.

The Role of Biodegradable Materials in a Larger Sustainability Strategy

Biodegradable materials for products are one important piece of the broader push toward sustainable product development and the wider adoption of eco friendly materials. When combined with recycled materials for product design and responsibly sourced sustainable raw materials, they create a robust framework for environmental responsibility.

GID Company supports this holistic approach by integrating biodegradable options into long-term development roadmaps. Whether your goal is reducing landfill waste, meeting specific environmental certifications, or enhancing your brand image in eco-conscious markets, we tailor your material selection strategy with precision.

Using Recycled Materials for Product Design

Recycled materials for product design are critical to reducing industrial waste and creating circular systems in modern manufacturing. As sustainability shifts from being a brand advantage to an expectation, businesses across the United States—especially in California, Texas, Florida, Georgia, Arizona, and Utah—are seeking ways to adopt eco friendly materials that align with market demands. At GID Company, we guide our clients in transforming recycled inputs into high-performance products that meet both functional and environmental standards.

Post-Consumer and Post-Industrial Plastics

Post-consumer plastics are collected from everyday waste streams such as bottles, packaging, and containers. These plastics, once recycled, are reprocessed into resins that can be molded into new components. Post-industrial plastics, on the other hand, are byproducts or scrap materials generated during manufacturing. Both categories offer viable recycled materials for product design that help minimize dependence on virgin resources.

GID Company evaluates the source, purity, and performance characteristics of each recycled polymer to ensure compatibility with the intended product function. Our approach blends eco friendly materials with engineering insight, helping clients maintain quality while supporting sustainable innovation.

Recycled Metals and Alloys

Recycled metals such as aluminum, steel, and copper play a major role in sustainable product development. These materials can be melted and reused repeatedly without degradation in quality, making them prime examples of eco friendly materials with long-term viability. For industries that demand high structural integrity, recycled metals offer a balance between performance and sustainability.

At GID Company, we often integrate recycled metals with biodegradable materials for products that require both strength and environmental consciousness. This hybrid design strategy allows our clients to meet diverse performance needs while advancing their sustainability agenda.

Textiles, Glass, and Composite Reuse

Beyond plastics and metals, recycled materials for product design also include textiles, glass, and industrial composites. These components are now central to how eco friendly materials are applied in modern development. Recycled textiles can be repurposed into padding, insulation, or soft-shell product layers. Glass cullet is commonly used in decorative or rigid applications. Advanced recycled composites, which blend polymers and natural fibers, are being increasingly used as eco-friendly product materials for structural and cosmetic components.

GID Company supports clients by identifying which of these options align best with product lifecycle goals, consumer preferences, and manufacturing workflows. We ensure that every recycled input functions as part of a broader system of sustainable raw materials.

Closed-Loop Design and Circular Systems

Closed-loop design involves the use of materials that can be recycled at the end of a product’s life and reintroduced into the supply chain. This philosophy drives long-term sustainability and reduces environmental burdens. Products built with recycled materials for product design can be intentionally structured to allow easy separation and reuse of components, supporting a circular economy.

GID Company helps clients assess the performance profile of recycled components alongside biodegradable materials for products and other eco friendly materials, including eco-friendly product materials. Our multi-criteria evaluation approach ensures that products not only support sustainability but also maintain performance, safety, and aesthetic appeal.

Evaluating Trade-Offs in Recycled Material Selection

Choosing recycled materials for product design requires careful consideration of trade-offs. Not all recycled inputs perform equally across tensile strength, color stability, or heat resistance. While their environmental benefit is clear, recycled materials must still meet demanding product requirements to ensure consumer satisfaction.

GID Company helps clients assess the performance profile of recycled components alongside biodegradable materials for products and other eco-friendly product materials. Our multi-criteria evaluation approach ensures that products not only support sustainability but also maintain performance, safety, and aesthetic appeal.

Regional Access and Supply Chain Logistics

The availability of recycled materials varies significantly across different regions. In states like Georgia and Arizona, proximity to recycling facilities can impact material cost, lead time, and quality consistency. GID Company taps into its network of vetted suppliers to secure reliable access to recycled feedstocks that match our client’s sustainability and production goals.

We align material selection with local infrastructure to reduce transportation emissions and streamline development workflows. Whether working with recycled plastics, sustainable raw materials, or hybrid blends, our regional insight gives our clients a competitive edge in building with eco friendly materials.

Integrating Sustainable Raw Materials Beyond Biodegradable & Recycled

Sustainable raw materials expand the possibilities of eco conscious product design beyond the usual scope of biodegradable materials for products and recycled materials for product design. These materials are responsibly sourced from renewable or ethically managed sources and offer long-term supply stability. At GID Company, we help clients evaluate and integrate sustainable options that support innovation, reduce carbon impact, and meet emerging market demands for responsible manufacturing.

Bio-Based Resins and Natural Composites

Bio-based resins, derived from plant oils or agricultural residues, are emerging as key sustainable raw materials in product design. These resins are formulated to replace petroleum-based counterparts without compromising structural integrity. When combined with natural fibers, they form robust composites ideal for durable goods and consumer-facing applications.

GID Company uses these combinations strategically, especially when biodegradable materials for products don’t meet the performance standards required by the product. Bio-resins provide a balance between environmental benefits and functional durability, making them a dependable addition to a growing list of eco friendly materials used in responsible design.

Plant-Based Leathers and Alternative Textiles

Plant-based leathers made from materials like apple skins, mushroom mycelium, or cactus fibers are quickly becoming preferred eco-friendly product materials and are also counted among the most innovative eco friendly materials in soft-touch and lifestyle-oriented products. These alternatives mimic the look and feel of traditional leather while offering improved biodegradability and ethical sourcing advantages.

At GID Company, we help clients select plant-based alternatives that fit brand aesthetics, durability requirements, and user experience expectations. Whether used in fashion accessories or tech device coverings, these materials serve as high-performance, sustainable raw materials that enhance a product’s environmental profile and appeal to eco-conscious consumers.

Hybrid Material Innovations

Hybrid material systems—combinations of eco friendly materials like natural fibers, bio-resins, and recycled content—allow for custom performance solutions in advanced applications. These engineered hybrids offer the opportunity to address specific design challenges while maintaining sustainability as a core principle.

For example, combining recycled materials for product design with natural binders can increase durability while keeping the product biodegradable under certain conditions. GID Company develops and tests these hybrids extensively to ensure they deliver measurable value across mechanical, aesthetic, and environmental metrics.

Lifecycle Analysis and Long-Term Value

The long-term value of using sustainable raw materials lies in their contribution to reducing total environmental footprint. A lifecycle analysis reveals that eco friendly materials can outperform traditional ones when measured over time, especially in reducing emissions, energy use, and landfill impact.

GID Company incorporates lifecycle thinking into every design decision. From the initial concept through to production and end-of-life planning, we ensure that sustainable raw materials are not just used, but fully optimized. Whether our clients are designing in California, Texas, or Florida, this strategic approach makes environmental accountability part of the product DNA.

Certification, Traceability, and Ethical Sourcing

For a material to qualify as truly sustainable, traceability and third-party certification are essential. Certifications ensure that eco-friendly product materials are harvested or produced under ethical, low-impact conditions. Transparent sourcing also supports supply chain integrity and builds consumer trust.

GID Company assists clients in verifying the origins and compliance of all sustainable raw materials. We work with suppliers who maintain ethical sourcing practices and provide full documentation, ensuring that your brand can confidently claim the use of verified eco friendly materials.

Bridging Innovation and Manufacturability

Innovative materials must be more than sustainable—they must also be manufacturable. Eco friendly materials, including sustainable raw materials, can sometimes pose challenges in tooling, tolerance, or surface finishing. These practical considerations often determine whether a sustainable material can make it from prototype to production.

At GID Company, we bridge this gap by using in-house prototyping and testing to ensure that eco-friendly product materials perform reliably on the manufacturing floor. We collaborate with clients to balance creative ambition with operational feasibility, building products that not only look good on paper but succeed in the real world.

Comparing and Prioritizing Eco-Friendly Product Materials

Selecting the right eco friendly materials is not just a matter of environmental preference—it’s a business-critical decision that affects performance, marketability, and lifecycle value. At GID Company, we help clients weigh their options across a variety of factors, from durability and cost to consumer appeal and sustainability benchmarks. A structured comparison ensures every material used in product design supports long-term success and aligns with growing regulatory and consumer expectations in states like California, Texas, and Florida.

Understanding Material Metrics That Matter

Every product presents a unique set of requirements. Some need strength and rigidity, while others must be lightweight and flexible. Evaluating eco friendly materials, especially eco-friendly product materials, requires looking beyond their environmental attributes to consider how they will perform over time.

GID Company uses a matrix-based comparison method, evaluating options like biodegradable materials for products and recycled materials for product design against metrics such as thermal stability, impact resistance, and surface finish compatibility. This ensures that clients don’t just choose sustainable raw materials—they choose the right ones.

Scenario Mapping for Application-Specific Fit

Material choice should never be one-size-fits-all. Products intended for outdoor use in humid climates like Florida may demand different characteristics than those built for dry, arid conditions in Arizona. Through scenario mapping, GID Company aligns eco friendly materials with the real-world environments in which your product will operate.

For instance, biodegradable materials for products may be ideal for single-use or short-lifecycle applications, while recycled materials for product design are more suitable for durable goods requiring long-term resilience. This tailored approach helps clients maximize both functionality and sustainability.

Cost, Availability, and Supply Chain Considerations

Even the most innovative sustainable raw materials must be available at scale and within budget to make commercial sense. GID Company helps clients evaluate the true cost of implementation, factoring in sourcing complexity, minimum order quantities, and lead times across different regions.

In markets like Georgia and Utah, local access to certain recycled inputs or bio-based resources can significantly lower production costs and reduce emissions. We strategically recommend eco friendly materials based on their availability and logistics profile to keep sustainability both accessible and profitable.

Balancing Aesthetics with Performance

Many clients are concerned with how eco friendly materials and sustainable materials affect the visual and tactile experience of their products. Whether it’s the organic texture of biodegradable components or the clean look of recycled plastics, aesthetics play a key role in consumer perception.

GID Company works closely with clients to ensure that eco-friendly product materials align with brand identity without compromising function. If a sustainable material impacts texture or color, we provide design solutions to maintain premium quality standards. Our expertise ensures that form and function support one another seamlessly.

Regulatory Compliance and Market Positioning

Using the right eco friendly materials can also be a strategic move to enter new markets or meet future regulatory requirements. States like California are setting stricter mandates for environmental impact, and adopting sustainable raw materials early can offer a competitive advantage.

GID Company ensures that every material considered meets or exceeds current environmental regulations and is positioned to comply with future updates. This foresight not only avoids legal pitfalls but also enhances your brand’s credibility in sustainability-focused sectors.

Creating a Prioritized Material Strategy

To simplify decision-making, GID Company helps clients rank eco friendly materials, including eco-friendly product materials, based on weighted criteria—performance, cost, environmental benefit, and supply risk. This strategic framework results in a prioritized materials roadmap that adapts to your product timeline, budget, and sustainability targets.

Whether choosing between recycled materials for product design or exploring next-generation biodegradable materials for products, our structured strategy gives clients clarity and confidence. With a solid material hierarchy, projects move forward faster, smarter, and greener.

Design Strategies & Best Practices for Implementation

Incorporating eco friendly materials into a product’s design is more than a materials swap—it’s a shift in design thinking. At GID Company, we approach sustainability as a practical design challenge, helping our clients reimagine their products without compromising performance, usability, or marketability. With strategic planning and smart implementation, eco-friendly product materials can become an integral part of successful, scalable product development.

Design for Disassembly and End-of-Life

One of the core strategies in sustainable design is to create products that can be disassembled easily at the end of their useful life. This enables separation of biodegradable materials for products and recycled components, ensuring each part can be properly processed or repurposed.

GID Company designs products with modular structures and accessible fasteners to support responsible disassembly. This technique reduces contamination between material types and simplifies the recycling or composting of eco friendly materials, further extending their environmental benefits.

Material Substitution Techniques

Replacing traditional inputs with sustainable raw materials often requires adapting product geometry, tolerances, or surface finishes. Each type of eco friendly material, especially those used as eco friendly materials in technical applications, behaves differently under stress, temperature, and load. Successful substitution depends on knowing where adjustments are needed without sacrificing the integrity of the final product.

GID Company works with engineering teams to modify tooling, dimensions, and structural reinforcements, allowing for smooth integration of recycled materials for product design or plant-based alternatives. This ensures that design shifts are intentional and performance-tested, not last-minute compromises.

Aligning Coatings and Finishes with Sustainability

Eco friendly materials can be rendered ineffective if finished with coatings or adhesives that are not environmentally compliant. Many sustainable raw materials react differently to traditional treatments, requiring new finishing methods that preserve biodegradability and recyclability.

At GID Company, we recommend finishes that match both the performance profile and environmental goal of the chosen materials. This includes water-based coatings, solvent-free adhesives, and sealants designed for compatibility with biodegradable materials for products. This attention to detail safeguards the sustainability of the entire design.

Early Prototyping and Material Testing

Testing eco friendly materials, including eco-friendly product materials, early in the design process is essential for reducing risk and ensuring manufacturability. Material properties can vary from batch to batch, especially in the case of recycled inputs or agricultural waste-based components.

GID Company conducts prototype evaluations using production-intent materials, simulating real-world conditions to validate strength, flexibility, and visual appeal. By confirming the behavior of recycled materials for product design or new bio-composites under operational stress, we reduce the likelihood of late-stage design failures.

Supply Chain Collaboration and Scalability

A good design is only sustainable if it can be manufactured reliably. Working with eco friendly materials often involves more than just sourcing—it requires tight coordination between suppliers, processors, and assembly teams.

GID Company ensures that supply chain partners understand the material requirements, handling limitations, and quality control measures associated with sustainable raw materials. This collaborative approach minimizes production delays and ensures that biodegradable materials for products arrive ready for consistent manufacturing at scale.

Educating Stakeholders on Sustainable Design

Internal alignment is a critical part of implementing eco friendly materials successfully. Product managers, engineers, marketers, and operations teams must all understand the value and constraints of the materials being used.

GID Company helps our clients build internal awareness through documentation, training, and decision frameworks that highlight the impact of using eco-friendly product materials. We foster a shared understanding across departments, helping our clients make sustainability an organization-wide priority—not just a design feature.

Future Trends & Innovations in Eco Friendly Materials

The future of product development will be defined by how well companies can adopt and evolve with eco friendly materials. As regulations tighten and consumer expectations continue to shift, innovation in sustainable material science is accelerating. At GID Company, we not only follow these trends—we help shape them. By staying ahead of the curve, we ensure our clients benefit from next-generation materials that enhance performance while reinforcing sustainability goals.

Emerging Bio-Based Material Technologies

Bio-based innovation is moving beyond traditional plant fibers into more advanced applications of eco friendly materials. Engineered biodegradable materials for products now include enhanced biopolymers capable of withstanding greater thermal and mechanical stress. These new materials outperform earlier generations while still offering compostability or environmental degradability under specific conditions.

GID Company monitors advancements in these categories to provide clients with high-performance alternatives to conventional plastics. We evaluate how these new eco-friendly product materials can serve in both short-term and long-life products across sectors such as consumer electronics, medical devices, and home goods.

Smart and Functional Eco Materials

The next wave of eco friendly materials is increasingly intelligent. Smart materials, including temperature-sensitive, shape-shifting, or moisture-reactive systems, are being developed using sustainable raw materials. These options provide functional benefits—such as self-healing, sensing, or energy transfer—while still meeting environmental goals.

At GID Company, we explore how these materials can be integrated into innovative products that go beyond basic functionality. Whether it’s a sensor embedded in recycled materials for product design or biodegradable casings that dissolve after single-use applications, we help our clients apply these innovations meaningfully and effectively.

Advanced Recycling and Material Regeneration

Recycling is moving beyond mechanical grinding and melting. Chemical and enzymatic recycling processes now allow for purer regeneration of raw materials from waste. This opens new possibilities for recycled materials for product design that maintain their original strength, clarity, or flexibility, making them suitable for higher-grade uses.

GID Company evaluates these technologies for feasibility at scale, especially in regions like Texas and Georgia where local recycling infrastructure is expanding. These processes help expand the pool of eco friendly materials without depleting natural resources or compromising on quality.

Circular Economy Integration in Design Thinking

Circular design is no longer an afterthought—it’s becoming a foundational part of product strategy. This approach emphasizes using materials that can be returned to the production cycle through recycling, composting, or regenerative systems. Eco friendly materials, especially eco-friendly product materials, play a central role in making this concept actionable.

GID Company works with clients to design products that support this lifecycle—from using biodegradable materials for products that decompose safely, to selecting recycled content that re-enters supply chains. This vision of continual use ensures sustainable raw materials become part of a regenerative, rather than extractive, product system.

Policy-Driven Material Evolution

As government policies across California, Florida, and Utah become stricter about environmental impact, companies are being pushed toward faster adoption of eco friendly materials. Incentives and restrictions are driving innovation, accelerating the availability and affordability of next-generation sustainable raw materials.

GID Company helps clients stay ahead of the regulatory curve by integrating compliant materials before they become mandatory. Our proactive approach ensures your products are not only built to today’s standards, but future-proofed for tomorrow’s expectations in eco-conscious markets.

Material Innovation as Brand Differentiation

The use of cutting-edge eco friendly materials is becoming a strong differentiator for forward-thinking brands. Consumers are rewarding companies that take bold steps toward sustainability. Material transparency, recyclability, and ethical sourcing are influencing purchase decisions more than ever before.

GID Company positions its clients as industry leaders by introducing innovative biodegradable materials for products and cutting-edge recycled materials for product design. We create products that stand out not just for performance, but for the environmental stories they tell—stories backed by the thoughtful use of eco-friendly product materials at every level of design.