In today’s fast-paced tech landscape, bringing a new electronic product to life demands more than just a great idea. It calls for a seamless partnership between design innovation and manufacturing precision. This blend of creativity and execution is where value is truly created. As the complexity of consumer expectations rises, especially in regions like California, Texas, and Florida, so does the demand for smarter, faster, and more collaborative development cycles.

At GID Company, we understand that successful product development is no longer a one-stage process. It’s a continuous interaction between multiple disciplines—mechanical, electrical, software, and of course, manufacturing. From concept to commercialization, every step matters. That’s why we believe in dissolving traditional barriers between design and production. We champion a smarter way of working—where Electronic Design and Manufacturing function as a single, cohesive unit.

This isn’t just an industry trend. It’s a strategic evolution. And GID Company is helping clients across the U.S., from Arizona to Georgia, ride that wave of transformation with speed and confidence. With a focus on time efficiency, cost-effectiveness, and product quality, we ensure your journey from idea to market is as frictionless as possible.

The Imperative of Electronic Design and Manufacturing Collaboration

The importance of alignment between design and manufacturing isn’t just theoretical. It’s a tangible advantage that businesses can harness to outperform the competition. When these two worlds operate in silos, delays, cost overruns, and product failures often follow. But when they’re united under one vision, the results are streamlined development cycles, higher product reliability, and accelerated time-to-market.

Defining the Collaboration

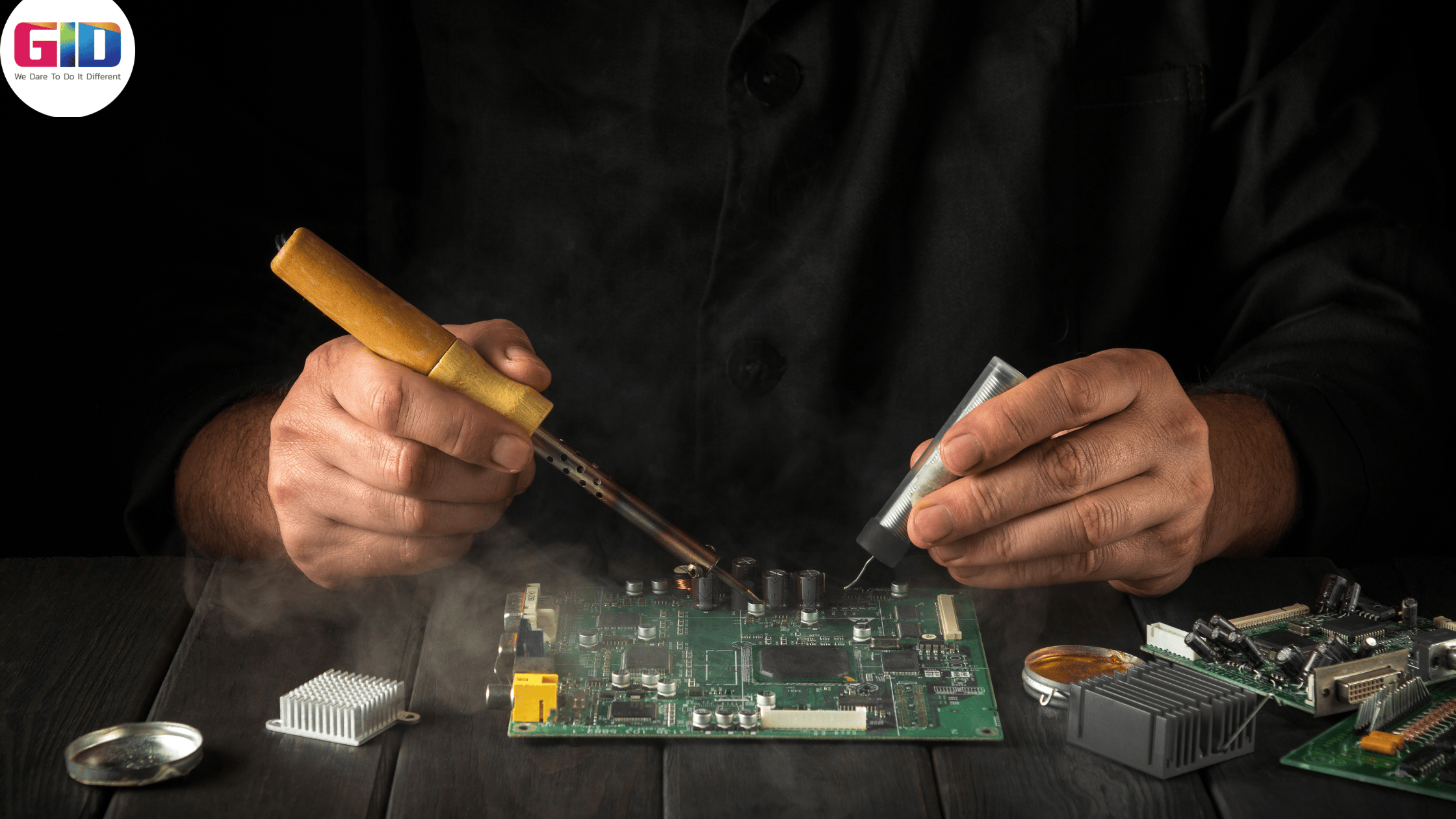

Electronic Design and Manufacturing is not merely about putting pieces together. It’s about synchronizing design intent with production reality. This means understanding the physical limitations of components, optimizing for manufacturability, and integrating every decision from layout to assembly with production in mind.

At GID Company, our teams work shoulder-to-shoulder from day one. Our designers know what our manufacturers need—and vice versa. This integrated approach minimizes design iterations, improves component sourcing, and ensures smoother transitions from prototype to volume production.

Why Timing and Integration Matter

Speed is a competitive edge. Markets in Utah, Texas, and Florida are moving fast, and waiting months to fix design flaws or tooling mismatches is no longer acceptable. Electronic Design and Manufacturing performed in harmony avoids these delays.

By introducing manufacturability reviews early in the design phase, GID Company helps clients avoid costly reworks. Our in-house capabilities allow rapid prototyping, functional testing, and feedback loops that align with real-world production conditions. The result is not just faster development but smarter development—tailored to scale with your product ambitions.

Cost Efficiency and Risk Reduction

The longer issues go undetected, the more expensive they become. Isolated teams often discover incompatibilities too late—after production is underway or worse, after product launch. An integrated Electronic Design and Manufacturing company like GID Company mitigates these risks through concurrent engineering and shared accountability.

This approach helps identify potential pitfalls before they escalate into failures. From thermal performance to circuit integrity, every aspect is validated with a production-first mindset. The ability to simulate, analyze, and adapt in real time helps us deliver cost-effective solutions without compromising on innovation.

From Concept to Execution: GID Company’s Seamless Collaboration Model

At the core of our service model is communication. Our engineers and production experts use a collaborative digital workflow that keeps everyone aligned. Whether designing wearables in Arizona or automation systems in Georgia, GID Company ensures every handoff is smooth, transparent, and optimized for success.

This end-to-end visibility doesn’t just reduce friction—it unlocks opportunity. Our clients can make better decisions, pivot faster when needed, and launch products with greater confidence. That’s the power of unified Electronic Design and Manufacturing, and it’s what GID Company delivers every day.

You May Also Like: Steri-Write Portfolio

Leveraging an Electronic Design and Manufacturing Company for Integrated Solutions

Combining design and manufacturing under one roof isn’t just convenient—it’s strategic. When you collaborate with an experienced Electronic Design and Manufacturing company, you eliminate fragmentation and open the door to faster, smarter innovation. This is exactly how GID Company supports clients across California, Florida, and Georgia—delivering results that resonate in competitive markets.

Unified Teams, Unified Goals

In traditional development models, teams often operate in isolation. Designs get passed along like relay batons—each handoff introducing delays, confusion, or misalignment. A unified Electronic Design and Manufacturing company eliminates this barrier. At GID Company, our teams function as one integrated unit, sharing tools, insights, and timelines.

This approach ensures every project begins with the end in mind. From the early electrical schematics to the final production-ready design, each step is optimized for efficiency. Collaboration happens in real time, not through documents or revisions, which means less friction and more forward motion.

Streamlined Prototyping and Testing

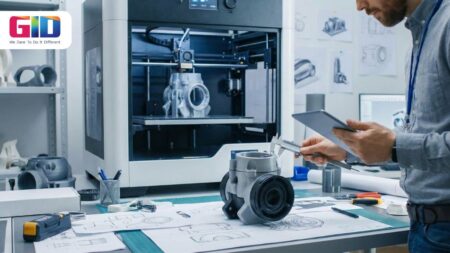

One of the greatest advantages of choosing a complete Electronic Design and Manufacturing company is the speed of iteration. At GID Company, we can take a concept from design to physical prototype quickly, thanks to in-house capabilities and synchronized processes.

This means faster validation cycles and immediate feedback from our manufacturing team. In regions like Utah and Arizona, where timelines are critical for tech launches and industrial innovations, this advantage can be the difference between first-to-market and lost opportunity. With our tight control over both design and fabrication, we drastically reduce turnaround times and prevent bottlenecks.

Cost Control Without Cutting Corners

Working with separate vendors often leads to duplicated efforts, inconsistent pricing, and unanticipated costs. A full-service Electronic Design and Manufacturing company like GID Company minimizes these risks through budget-aligned planning and lifecycle management.

We analyze cost implications during the design phase itself—selecting components, materials, and layouts that balance performance with scalability. This integrated budgeting ensures that production realities never blindside the project. It’s how we help clients in Texas and other fast-moving markets keep both quality and profitability in check.

The Role of an Electronic Design Agency in Product Innovation

While manufacturing is about execution, design is where innovation begins. A skilled electronic design agency doesn’t just create blueprints—it engineers possibilities. When design is strategic, every decision adds value. And when that design is integrated with manufacturing from day one, the results are game-changing. GID Company brings this mindset to every project, combining design excellence with practical deliverability.

Crafting Innovation with Intent

At its core, an electronic design agency translates ideas into functional systems. But not every design is created equal. Poorly planned layouts or incompatible components can derail even the most brilliant concept. That’s why GID Company operates with an innovation-first mindset, but grounded in manufacturability.

Whether we’re designing smart home systems in Georgia or medical wearables in Florida, our approach balances creativity with precision. We evaluate thermal performance, board real estate, signal integrity, and component availability—all in the early stages. This ensures the final product is not only cutting-edge but also practical to build.

Bridging Vision with Engineering

Many clients come to us with raw ideas or partial concepts. As a full-service electronic design agency, GID Company takes those initial sparks and engineers them into complete, market-ready products. Our designers collaborate closely with our manufacturing engineers, ensuring that every concept aligns with production capability.

This ongoing dialogue enables rapid iterations without design detours. Our integrated digital platform supports simulation, testing, and cross-team validation. In states like California and Arizona, where tech startups and OEMs compete on speed and quality, this collaborative agility becomes a major asset.

Scaling Design for Production

Design isn’t finished at the prototype stage—it must scale. That’s where many standalone design agencies fall short. GID Company ensures every design is ready for real-world manufacturing by building in flexibility, traceability, and testability from the start.

We design with components that are readily available and production lines that are realistic. This way, when the time comes to scale—whether for a regional launch in Texas or a national rollout—the process is seamless. As an electronic design agency integrated with manufacturing, GID Company delivers designs that move smoothly from bench to build.

Regional Focus: GID Company’s Presence in Key U.S. Markets

While electronic product innovation is a global pursuit, local expertise matters. Understanding regional industries, supply chains, and regulatory nuances can make or break a project. GID Company doesn’t just deliver advanced Electronic Design and Manufacturing solutions—we bring them directly to the regions where they’re needed most. Our presence across California, Texas, Florida, Arizona, Utah, and Georgia allows us to offer targeted support that aligns with each state’s unique business landscape.

California: Powering Tech and Startups

California is a global technology leader. From Silicon Valley to San Diego, businesses demand fast, scalable, and reliable product development. GID Company provides Electronic Design and Manufacturing services tailored for this high-speed environment.

We collaborate closely with local innovators, ensuring designs meet cutting-edge expectations while aligning with scalable production strategies. Whether it’s IoT solutions, advanced wearables, or consumer electronics, our integrated workflow supports faster validation and launch cycles.

Florida: Driving Medical and Marine Innovation

Florida’s industries span from healthcare to marine tech, both requiring precision and regulatory awareness. As a full-spectrum Electronic Design and Manufacturing company, GID Company delivers compliant, reliable solutions for these specialized sectors.

We partner with startups and enterprises across the state to translate complex requirements into functional devices. Our in-house team manages every phase—from early ideation through design verification and final assembly—ensuring that medical and marine products meet stringent safety and performance standards.

Utah and Texas: Supporting Industry, Automation, and Energy

Utah and Texas are hotbeds for industrial automation and clean energy innovation. GID Company supports these industries through robust, field-tested solutions that combine durability with smart design.

By integrating electronic design agency capabilities with real-world manufacturing expertise, we help businesses in these states develop rugged systems for demanding environments. From automation controls to energy monitoring devices, our Electronic Design and Manufacturing approach ensures products are built to last and scale.

Arizona and Georgia: Elevating Aerospace and Smart Home Sectors

Arizona’s aerospace legacy and Georgia’s growing smart home market both require tight development timelines and technical precision. GID Company works hand-in-hand with clients in both regions to streamline the entire product lifecycle.

As a trusted electronic design agency and manufacturing partner, we bring agility and structure to complex projects. Our local engagement ensures faster support, clearer communication, and the ability to adapt quickly when market demands shift.

Read Also: Beyond Schematics: Essential Guide to Electronic Design

GID Company’s Collaborative Workflow: From Concept to Market

At GID Company, we don’t see product development as a sequence of stages—we see it as a continuous cycle of innovation. By uniting design creativity with manufacturing discipline, we create a seamless path from concept to market. This integrated Electronic Design and Manufacturing workflow empowers clients to move faster, iterate smarter, and scale confidently.

Discovery and Planning

Every great product begins with a clear vision. During the discovery phase, GID Company works closely with clients to define goals, understand user needs, and identify key technical requirements. Our team of engineers, designers, and project managers creates a roadmap that aligns innovation with feasibility.

As both an electronic design agency and manufacturer, we evaluate risks early—resolving potential bottlenecks before they disrupt timelines or budgets. This proactive planning ensures your product journey starts on solid ground.

Integrated Design and Engineering

The next phase brings design and engineering together under one roof. GID Company’s multidisciplinary teams collaborate using a unified toolset, which means designs are built with production realities in mind. We handle schematic development, PCB layout, embedded software, and enclosure design in one synchronized environment.

Because our approach is rooted in Electronic Design and Manufacturing, our engineers communicate directly with our fabrication teams. This coordination leads to cleaner handoffs, reduced revisions, and prototypes that function as intended on the first build.

Prototyping, Testing, and Validation

Speed alone is not enough—accuracy matters just as much. GID Company builds and tests rapid prototypes using real components and production-intent materials. We validate performance across multiple parameters including durability, compliance, and user experience.

Unlike standalone services, our Electronic Design and Manufacturing company ensures that every prototype phase transitions effortlessly into production planning. Feedback loops are short and actionable, allowing fast iterations without loss of continuity or data.

Production and Market Launch

When it’s time to scale, GID Company is already a step ahead. Our Electronic Design and Manufacturing capabilities support low to high-volume production, with full traceability and quality assurance at every stage.

We coordinate final testing, packaging, and logistics in close alignment with your go-to-market strategy. Whether launching regionally in Texas or nationally from California, our integrated approach means fewer delays, better quality, and smoother deliveries. As both your electronic design agency and manufacturing expert, we ensure your product not only works—but wins.

Wrapping Up: Empowering Innovation Through Unified Development

Seamless Integration for Market Success

In today’s competitive landscape, the fusion of design ingenuity and manufacturing excellence is paramount. GID Company’s integrated approach to Electronic Design and Manufacturing ensures that every product is developed with both creativity and practicality in mind. By harmonizing these disciplines, we help clients across California, Texas, Florida, and beyond bring innovative products to market efficiently and effectively.

Your Strategic Partner in Product Development

Choosing the right partner is crucial for product success. As a comprehensive Electronic Design and Manufacturing company, GID Company offers end-to-end solutions that streamline the development process. Our expertise as an electronic design agency enables us to transform ideas into tangible products, ensuring quality and scalability. Whether you’re launching a new device in Arizona or expanding your product line in Georgia, our collaborative approach positions your business for success.