It usually doesn’t start in a lab.

It starts late at night, staring at a sketch that refuses to stay quiet. An idea that keeps tapping you on the shoulder, asking to be built. You know it could work—but you also know hardware doesn’t forgive mistakes.

This is the moment we see founders reach out to GID Company from California, Texas, Florida, Arizona, Georgia, and Utah. Not because they lack ideas—but because they understand what’s at stake. Electronics aren’t forgiving. One wrong assumption can cost months. One rushed decision can bury a budget.

That’s where the real journey begins. And that’s exactly where we step in—not as spectators, but as guides who’ve walked this terrain before.

Electronic Product Development: Turning “What If?” Into a Real Plan

Electronic product development isn’t about jumping straight into building. It’s about knowing what to build, why it matters, and how to avoid the cliffs along the way.

At GID Company, we treat this phase like plotting a route across unfamiliar ground. Every decision—technical or strategic—either moves you closer to market readiness or quietly pushes you off course.

What “Market-Ready” Actually Means

Market-ready doesn’t mean “it powers on.” It means the product works reliably, can be manufactured consistently, and survives real-world use—not just lab tests. It’s the difference between a clever prototype and something customers trust.

How GID Company Keeps You Out of Trouble

We slow things down early so you can move faster later. Clear requirements. Honest feasibility checks. Early risk identification. This approach saves time, money, and momentum—especially for founders building in fast-paced regions like California or scaling-focused markets like Texas and Georgia.

Electronic Product Design: When Ideas Become Systems

Every successful product reaches a moment where imagination must give way to structure. This is where electronic product design takes center stage.

Design isn’t just how it looks. It’s how power flows, how components communicate, how heat escapes, and how users interact without thinking.

At GID Company, we design electronics as complete systems, not disconnected parts. That means considering enclosure constraints, usability, component lifecycles, and real manufacturing limits—all at once.

This systems-first thinking is especially critical for founders operating in competitive markets like California and Florida, where speed and reliability decide who wins.

Electronic Product Design and Development: Where Coordination Makes or Breaks the Build

Electronic product design and development fails when teams move in silos. Hardware races ahead. Firmware lags behind. Mechanical design gets locked too early.

We prevent that.

GID Company runs design and development as parallel tracks, constantly synchronized. Electronics, firmware, and mechanical decisions evolve together—guided by milestones, not guesswork.

This approach keeps momentum steady, whether you’re coordinating teams across Utah and Arizona or building locally in Texas.

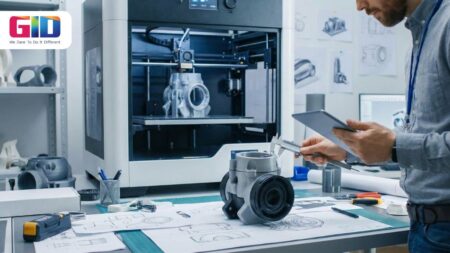

Electronics Prototyping: The First Time the Product Speaks Back

There’s a moment when theory meets reality.

Electronics prototyping is when assumptions get challenged—and that’s a good thing. This is where products reveal their personality: power quirks, signal noise, thermal surprises.

We treat prototypes as learning tools, not trophies. Each build answers specific questions and informs the next decision. No wasted iterations. No vague “let’s see what happens.”

For our clients, this stage often feels like relief. The product finally exists. And it’s finally talking back.

Electronic Prototype Design: From Experimental to Dependable

Electronic prototype design is where discipline matters most.

Early boards are allowed to be imperfect. Later ones aren’t.

At GID Company, we evolve prototypes with production in mind—clean layouts, thoughtful component selection, test access, and firmware alignment. This prevents painful redesigns when it’s time to scale.

Founders searching for support in product hubs like California or fast-growing regions such as Georgia and Texas benefit most from this forward-thinking approach.

Searching “Product Development Companies Near Me”: What Really Matters

When people search for product development companies near me, they’re not looking for buzzwords. They’re looking for confidence.

Confidence that someone understands electronics. Confidence that risks will be called out early. Confidence that progress won’t disappear behind jargon.

GID Company earns that trust by being clear, technical, and accountable. We don’t just show what’s possible—we explain what’s practical.

“Product Design Companies Near Me” vs. “Product Design Firms Near Me”

Not all design partners are built for electronics.

Many product design companies near me focus on visuals and concepts. That’s useful—but incomplete. Electronics demand deeper engineering ownership.

True product design firms near me for hardware must handle schematics, boards, firmware realities, and manufacturing constraints together. That’s the space GID Company lives in—end to end.

Manufacturing Readiness: When the Trail Meets Reality

This is where many products stumble.

Manufacturing readiness isn’t a single step. It’s preparation layered over time. Stable designs. Controlled costs. Reliable sourcing. Built-in testing.

We help clients prepare for this transition—whether they’re manufacturing locally in the U.S. or coordinating broader supply strategies from Texas or California.

Launch and Beyond: Products Don’t Stop Evolving

Launch isn’t the finish line.

Real-world use reveals new insights. Small refinements. Opportunities for version two. GID Company stays involved—supporting iteration, improvements, and next-generation planning.

Because successful products aren’t static. They adapt.

Wrapping Up: The Idea That Made It Across

Every product begins as a question.

The ones that survive are guided—carefully, deliberately, and with respect for the terrain. GID Company exists to guide that journey, helping founders across California, Texas, Florida, Arizona, Georgia, and Utah turn ideas into dependable, market-ready electronics.

Not just built. Built right.