Rapid prototyping technologies are transforming the way products are brought to life in the United States. In a world where speed and precision are non-negotiable, these technologies offer a faster, more agile route from concept to market-ready design. For companies across California, Texas, Florida, Georgia, Arizona, and Utah, the evolution of product development depends not only on adopting new tools but also on partnering with firms that know how to apply them effectively.

At GID Company, we specialize in guiding clients through every stage of this transformation. Whether it’s refining initial concepts, reducing time-to-market, or improving product testing cycles, our end-to-end development services are built around cutting-edge techniques. With dedicated facilities and resources across the U.S., we provide regionally responsive support that aligns with your pace and expectations.

From medical devices and consumer electronics to industrial equipment and smart home systems, rapid prototyping technologies make it possible to iterate without delay and reduce the cost of innovation. With our expertise, businesses can shift from slow legacy processes to agile, feedback-driven workflows that yield real-time results. This proactive approach is not just beneficial—it’s essential in a competitive product landscape.

As we dive into the current wave of emerging methods, it becomes clear how much impact these changes are making across industries. GID Company remains at the forefront of this movement, helping innovators navigate the evolving prototyping ecosystem and bringing smarter, faster, and more resilient product solutions to life.

Emerging Rapid Prototyping Technologies

The landscape of rapid prototyping technologies is expanding at an unprecedented rate, driven by the demand for speed, precision, and customization. What once required weeks of manual modeling and machining can now be accomplished in days—or even hours—with the right mix of hardware, software, and strategy. For companies located throughout the U.S., from the tech corridors of Silicon Valley to manufacturing hubs in the South, these advancements are redefining what’s possible.

Definition and Scope

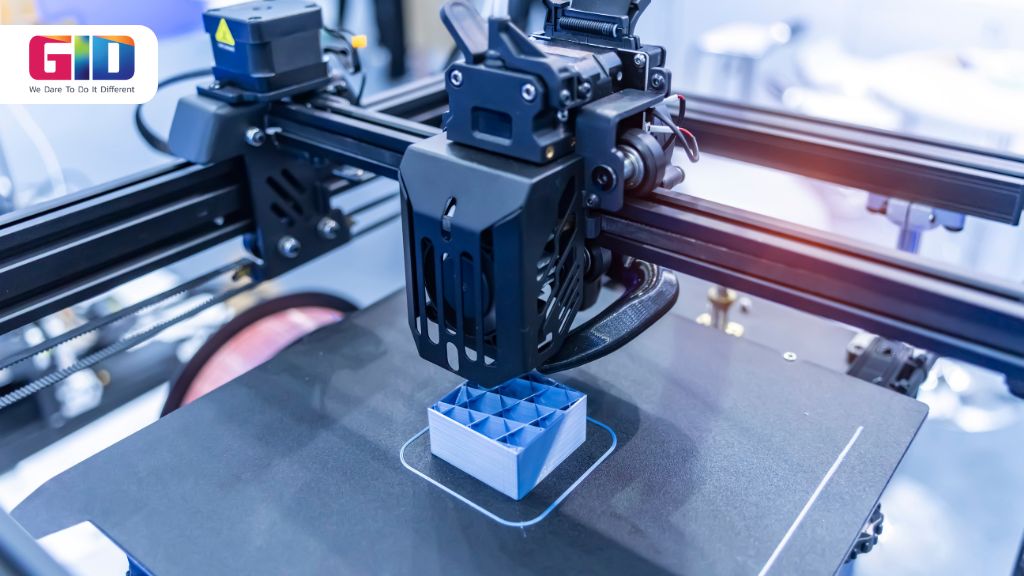

Rapid prototyping technologies refer to a class of methods used to quickly fabricate a physical model of a part or assembly using three-dimensional computer-aided design (CAD) data. These techniques prioritize efficiency, enabling fast iterations and functional testing without the delays associated with traditional manufacturing.

As part of GID Company’s integrated approach, we utilize multiple techniques that fall under this umbrella, including 3D printing for prototyping, CNC rapid prototyping, and additive manufacturing prototyping. These tools not only streamline development but also provide the accuracy needed to validate concepts in real-world conditions.

Technological Drivers

The surge in advanced prototyping methods is fueled by a combination of material innovations, automation, and software-driven customization. The introduction of smart polymers, high-strength composites, and conductive materials has opened new doors for functional prototypes that mimic final product performance. In parallel, the integration of AI and machine learning into CAD platforms allows for rapid iterations and predictive simulations—making them a valuable component of today’s rapid prototyping technologies.

GID Company leverages these advances through in-house platforms designed to adapt to specific client needs. Whether developing an ergonomic wearable or a complex mechanical system, we ensure that the most suitable prototyping pathway is applied.

U.S. Industry Trends

Across the United States, industries are aligning themselves with rapid prototyping technologies to outpace competition and satisfy customer demand. In California, product startups and medtech firms are leaning into 3D printing for prototyping due to its speed and adaptability. Meanwhile, Texas and Arizona are seeing a rise in CNC rapid prototyping for industrial and automotive sectors where high-precision metal parts are critical.

At GID Company, we’re strategically positioned to respond to these localized needs. Our teams operate across these states with deep knowledge of industry-specific requirements and the tools necessary to meet them. This ensures not only quality results but also efficient development lifecycles from concept to pre-production.

Integration with Additive and Subtractive Processes

The fusion of additive manufacturing prototyping with traditional subtractive techniques like CNC machining is one of the most impactful developments in recent years. By combining the flexibility of layered construction with the precision of cutting-based methods, designers can create complex geometries while still achieving tight tolerances, reinforcing the versatility of rapid prototyping technologies.

GID Company is uniquely equipped to handle this hybrid approach. Through advanced prototyping methods that include both additive and subtractive technologies, we deliver functional models that are as close to final products as possible—faster than conventional timelines would ever allow.

Future Readiness and Innovation

As rapid prototyping technologies continue to evolve, the line between prototype and production is blurring. Emerging trends such as real-time design iteration, cloud-based collaboration, and scalable small-batch production are setting the stage for a new era of manufacturing.

GID Company is actively investing in these future-forward strategies. Our clients not only benefit from today’s leading tools but are also prepared for tomorrow’s innovations. This commitment to progress ensures that every prototype is a step toward smarter, faster product development.

3D Printing for Prototyping: Next-Generation Methods

3D printing for prototyping is no longer confined to early-stage mockups or visual models. It has evolved into a high-performance solution within the broader family of rapid prototyping technologies. This shift is particularly valuable for startups and enterprises operating in dynamic markets across California, Florida, Texas, and other innovation-driven states. At GID Company, we offer comprehensive 3D printing services designed to enhance precision, accelerate iteration, and shorten time-to-market.

By integrating 3D printing into modern product development cycles, businesses are now able to test form, fit, and functionality in record time. And when this capability is paired with other rapid prototyping technologies like additive manufacturing prototyping and CNC rapid prototyping, the results are even more impactful.

Multi-Material and Hybrid Printing Capabilities

One of the major advances in 3D printing for prototyping is the ability to print with multiple materials in a single build process. This enables the creation of prototypes that more closely resemble finished products, complete with variable hardness, color segmentation, or functional zones. As part of comprehensive rapid prototyping technologies, this capability offers both speed and accuracy to design validation.

At GID Company, our 3D printing infrastructure supports hybrid builds that allow different polymers or composite blends to be layered together. This enables functional part testing at earlier stages of development and reduces the need for multiple separate builds.

High-Speed 3D Printing Technologies

Speed is one of the greatest strengths of next-gen 3D printing. Methods like continuous printing and volumetric techniques have drastically reduced the production time for prototype components. Instead of waiting days for complex geometries, teams can now hold functional parts within hours using rapid prototyping technologies designed for acceleration.

This kind of acceleration is a critical part of our workflow at GID Company. When integrated into a broader strategy involving advanced prototyping methods, this speed supports rapid validation cycles and streamlines go-to-market timelines. It also allows for more flexible response to customer feedback during development.

Metal 3D Printing and Structural Integrity

While plastic-based models remain important, metal 3D printing for prototyping has opened new opportunities in aerospace, automotive, and defense sectors. Titanium, aluminum, and stainless steel prototypes can now be produced using techniques that ensure both strength and geometric accuracy.

GID Company leverages this capability for clients who require durable, high-precision parts in the early phases of development. Whether for stress testing, mechanical alignment, or heat resistance evaluations, these metal prototypes fit perfectly within our broader array of rapid prototyping technologies. We also complement them with CNC rapid prototyping when extremely tight tolerances are necessary.

Functional Prototyping with Smart Materials

Beyond just appearance, functional testing is becoming a cornerstone of modern prototyping. This includes the integration of smart materials that respond to environmental inputs, such as temperature or pressure. These capabilities are made possible through additive manufacturing prototyping combined with advanced prototyping methods, enhancing the functional reach of today’s rapid prototyping technologies.

At GID Company, we use these innovations to help clients in industries like healthcare and consumer electronics test real-world functionality early. This cuts down on late-stage surprises and gives product teams the confidence to move forward toward production with well-validated designs.

Cross-Functional Integration

3D printing for prototyping rarely exists in a vacuum. It delivers maximum impact when integrated with other rapid prototyping technologies such as subtractive CNC processes, AI-driven generative design, and simulation-based modeling. This creates a multi-angle approach to development that enhances both speed and decision-making.

GID Company’s development model is built on this multi-pathway approach. By combining additive manufacturing prototyping and CNC rapid prototyping with next-gen 3D techniques, we offer clients in Georgia, Arizona, and beyond a complete solution. Whether the goal is to build, test, or iterate, we ensure every step aligns with strategic outcomes and product performance expectations.

Additive Manufacturing Prototyping Beyond 3D Printing

While 3D printing for prototyping often captures most of the attention in product development, additive manufacturing prototyping extends well beyond what desktop printers can deliver. As part of the broader evolution in rapid prototyping technologies, these advanced techniques bring new capabilities to engineers and product teams looking for higher performance, better material diversity, and scalable solutions. At GID Company, we incorporate a wide range of additive manufacturing processes that move beyond traditional boundaries and solve challenges conventional tools can’t.

By taking full advantage of advanced prototyping methods and integrating them with CNC rapid prototyping, we’re able to produce fully functional, test-ready prototypes at speeds that once seemed impossible. Our development centers across California, Texas, Arizona, and Florida are equipped to deliver this agility at a local level, with nationally consistent quality.

Beyond Layer-by-Layer: Binder Jetting and Lamination

Additive manufacturing prototyping today includes a variety of approaches that go well beyond the basic layer-by-layer extrusion model. Binder jetting, for example, enables the production of complex geometries in metals and ceramics without the need for high-temperature melting processes. Sheet lamination offers another path, allowing fast stacking of material layers which are bonded and shaped with precision.

These methods are particularly valuable when surface finish, build volume, or thermal resistance matter. GID Company integrates these processes into our rapid prototyping technologies portfolio to support clients working on mission-critical components or intricate designs. We apply our expertise to help determine the best-fit technique based on the end-use application, speed requirements, and budget.

Embedded Electronics and Functional Layers

One of the most powerful aspects of modern additive manufacturing prototyping is its ability to incorporate electronics and functional features directly into the printed parts. By embedding sensors, circuits, or conductive pathways during the print process, we create prototypes that are not just visual or structural—they’re functional and test-ready.

This advancement is a critical part of GID Company’s offering, especially for product categories like IoT devices, wearables, and smart tools. Our development teams in Georgia, Utah, and California are trained to integrate these functions early, reducing the number of revisions and eliminating the need for secondary assembly steps. This type of functional layering sits at the intersection of advanced prototyping methods and 3D printing for prototyping within a larger framework of rapid prototyping technologies.

Closed-Loop Feedback and Real-Time Quality Control

To maintain consistency and precision, additive manufacturing prototyping now often includes real-time measurement systems that adjust the process dynamically. These closed-loop feedback systems measure everything from dimensional accuracy to thermal behavior during the print, allowing instant corrections.

At GID Company, we’ve embedded this smart monitoring into our workflow. As a result, clients receive not just parts, but validated outputs that meet their performance and dimensional requirements from the first print. This is especially important when combining these techniques with CNC rapid prototyping in hybrid builds, where high-accuracy finishing requires a sound foundation. Such integration enhances the reliability of all our rapid prototyping technologies.

Custom Materials and High-Performance Applications

Another area where additive manufacturing prototyping shines is in material versatility. Custom polymers, composites, and metal alloys are now being developed specifically for functional testing. These material advancements continue to elevate rapid prototyping technologies by allowing tailored mechanical, chemical, and thermal properties suited for demanding industries.

GID Company works directly with material partners to ensure we have access to the most advanced options on the market. Our experts assess each project’s requirements and apply material science knowledge to guide selection and ensure compatibility with the selected prototyping technique. Whether it’s through 3D printing for prototyping or other advanced prototyping methods, our team ensures the right material is used every time.

Integration with Hybrid Manufacturing Workflows

The full power of additive manufacturing prototyping is unlocked when it’s strategically integrated with other approaches, particularly CNC rapid prototyping. By starting with additive processes for internal structures and shifting to CNC machining for outer finishes or tight tolerances, rapid prototyping technologies can deliver high-performance prototypes that are nearly production-ready.

GID Company excels at orchestrating this kind of hybrid workflow. Our engineering teams coordinate these processes across facilities to create seamless development experiences for clients in Texas, Florida, and beyond. The result is not only better prototypes, but a clearer path to production, with reduced lead times and improved performance alignment.

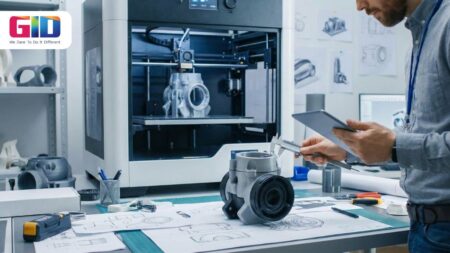

CNC Rapid Prototyping and Hybrid Subtractive-Additive Methods

CNC rapid prototyping involves the use of computer-controlled milling or turning machines to shape a part from solid blocks of material. This method excels at producing high-precision parts in metals and engineering-grade plastics. As part of the broader landscape of rapid prototyping technologies, it is particularly useful for validating tight tolerances, load-bearing designs, and mechanical assemblies.

This combined strategy is especially effective in applications where dimensional tolerances, material strength, and surface finish are critical. With facilities across California, Texas, and Arizona, GID Company offers localized access to this capability, supporting rapid development cycles across diverse industries.

CNC Rapid Prototyping: A Precision-Driven Approach

CNC rapid prototyping involves the use of computer-controlled milling or turning machines to shape a part from solid blocks of material. This method excels at producing high-precision parts in metals and engineering-grade plastics. It is particularly useful for validating tight tolerances, load-bearing designs, and mechanical assemblies.

At GID Company, we often recommend CNC rapid prototyping when surface finish, durability, or thermal properties are essential to product performance. Unlike some forms of additive manufacturing prototyping, CNC machining doesn’t rely on layering, which eliminates concerns about layer adhesion or anisotropic strength. It provides uniform material properties and finish that mimic production-level quality.

Complementing Additive Techniques with CNC Finishing

One of the most powerful uses of CNC rapid prototyping is in combination with additive manufacturing. When a part is first built using 3D printing for prototyping and then finished with CNC machining, it benefits from the design freedom of additive processes and the precision of subtractive finishing—making this hybrid approach a strong component of rapid prototyping technologies.

GID Company coordinates these dual workflows to ensure a seamless transition between the two. For example, a complex internal geometry might be printed in a high-strength resin, then post-processed with CNC finishing to refine external threads or bearing surfaces. This saves time and money while increasing accuracy and durability, helping clients move more confidently into production stages.

Material Versatility in CNC Rapid Prototyping

One of the main strengths of CNC rapid prototyping is the vast range of materials it supports. From aerospace-grade aluminum to high-impact polycarbonates, CNC machines can work with virtually any machinable material. Within rapid prototyping technologies, this adaptability plays a key role in meeting both performance and validation requirements.

At GID Company, we maintain a large inventory of commonly used materials to reduce lead times for our clients. Our CNC operations, based in states like Georgia, Utah, and Florida, are optimized for both prototyping and low-volume production. Whether your product requires thermal stability, impact resistance, or aesthetic precision, we ensure material and method alignment from the start.

High-Speed CNC and Agile Tooling

Advancements in rapid prototyping technologies now include faster CNC machines with shorter tool changeover times, adaptive control systems, and real-time error detection. These developments contribute to quicker turnaround without compromising quality. As part of GID Company’s suite of advanced prototyping methods, high-speed CNC plays a crucial role in our delivery model.

We design our tooling and fixture strategies to align with prototype goals. This includes rapid jig fabrication, soft tooling options, and integrated QA systems. These tools are not just about machining—they support faster iteration cycles that feed directly into design refinement and final product success.

Hybrid Workflows for Function and Form

In many projects, a single prototyping method is not sufficient to meet both functional and aesthetic requirements. That’s where hybrid strategies—using 3D printing for prototyping combined with CNC machining—create unique value. By harnessing both additive manufacturing prototyping and subtractive finishing within rapid prototyping technologies, product teams can achieve well-rounded results.

GID Company champions these multi-faceted development paths. From early-stage evaluation models to final-form prototypes ready for stakeholder presentations, we blend advanced prototyping methods into fully integrated solutions. Our focus is not only on speed, but on making every iteration smarter, more functional, and closer to your production vision.

Advanced Prototyping Methods and Supporting Technologies

The rapid growth of rapid prototyping technologies has led to the emergence of advanced prototyping methods that go far beyond traditional techniques. These newer methods enable faster cycles, smarter testing, and more accurate predictions of real-world product behavior. At GID Company, we implement these innovations to ensure that our clients get more than just prototypes—they get insight, performance, and scalability. Our locations in California, Florida, Utah, and other U.S. regions are equipped to support these cutting-edge workflows with full technical depth.

By combining 3D printing for prototyping, CNC rapid prototyping, and additive manufacturing prototyping with high-tech simulation and virtual testing, we help businesses reduce risks, cut down on redesigns, and stay ahead in competitive markets.

Generative Design and Topology Optimization

Generative design is a process where algorithms generate hundreds of design options based on specific goals and constraints. When paired with rapid prototyping technologies, it enables real-time testing of structures that traditional engineers might not have considered. These optimized forms often use less material, weigh less, and perform better.

GID Company leverages these advanced prototyping methods to help clients make data-driven decisions. After the design phase, we use 3D printing for prototyping to bring the generated designs into physical reality for hands-on validation. If certain parts require higher tolerance, CNC rapid prototyping complements the process by refining surfaces and geometry to match exact specs.

Simulation-Driven Prototyping Workflows

Simulation technology is changing how we approach prototyping. With real-time feedback on thermal, structural, and fluid dynamics, we can test prototypes in virtual environments before producing them. This not only shortens the iteration timeline but also reduces material waste and manufacturing costs.

At GID Company, we integrate simulation platforms directly into our additive manufacturing prototyping workflows. By analyzing stress points, heat zones, and mechanical movement virtually, we ensure each prototype performs as expected before it is built. This predictive power enhances the reliability of all our rapid prototyping technologies and ensures physical builds are already optimized for testing.

Agile Tooling and Soft Mold Integration

Agile tooling involves creating temporary molds, jigs, or fixtures that support short-run prototyping or pre-production testing. These tools can be fabricated quickly and affordably using 3D printing for prototyping or CNC rapid prototyping, depending on the part’s complexity and end-use. As an essential part of rapid prototyping technologies, this flexibility speeds up early validation.

GID Company uses agile tooling across industries to accelerate the prototyping-to-production pipeline. Soft tooling also allows for low-pressure molding of elastomeric or flexible components, supporting comprehensive prototyping for products that need to mimic final use conditions. These setups are essential when deploying advanced prototyping methods that require multiple material tests within tight timeframes.

Functional Testing with AR/VR Integration

Augmented and virtual reality are becoming essential in the evaluation of complex prototypes. These tools allow teams to visualize assembly, simulate user interaction, and identify design flaws without waiting for physical parts. They offer a new layer of validation within rapid prototyping technologies by simulating real-world scenarios in immersive detail.

At GID Company, we offer AR and VR integration as part of our advanced prototyping methods. Clients across Texas, Arizona, and Georgia use this capability to make faster, more informed design decisions. Once virtual models are approved, we shift to physical validation using 3D printing for prototyping and, when needed, CNC rapid prototyping for functional refinement.

Unified Digital Thread Across Prototyping

Advanced prototyping methods are most effective when supported by a digital thread—a continuous flow of data from concept through testing and into production. This unified approach ensures seamless data management and rapid collaboration across all stakeholders working with rapid prototyping technologies.

GID Company structures its development around this concept. We combine additive manufacturing prototyping, simulation tools, and physical production in one continuous process. This tight integration maximizes transparency, reduces delays, and ensures each stage of development builds logically on the one before it.

Comparative Evaluation & Decision Framework

With so many rapid prototyping technologies available today, selecting the right one for your product can be challenging without a structured evaluation. Every method—from 3D printing for prototyping to CNC rapid prototyping and additive manufacturing prototyping—has its strengths and trade-offs. At GID Company, we guide clients through a precise decision-making process that weighs technical needs, project goals, timelines, and cost factors. This framework ensures that each prototype supports not only testing but also long-term product strategy.

By comparing advanced prototyping methods based on specific criteria, businesses across California, Florida, Texas, and Utah can achieve a clearer understanding of what fits best—and why.

Aligning Methods with Design Intent

The first step in evaluating rapid prototyping technologies is understanding the intent behind the prototype. Is the goal to test functionality, validate form, or replicate real-use performance? Different objectives require different approaches. For instance, 3D printing for prototyping excels at visual and ergonomic validation, while CNC rapid prototyping is often better for testing assemblies that need precision and strength.

At GID Company, we assess each client’s design objectives and match them to the most suitable method. In many cases, additive manufacturing prototyping is ideal for testing intricate internal geometries, whereas more durable prototypes may require subtractive finishing as part of advanced prototyping methods.

Evaluating Speed, Cost, and Tolerance Requirements

No evaluation is complete without a comparison of speed, budget, and required tolerances. Projects with tight timelines may benefit from rapid additive techniques, while those needing fine tolerances might lean toward CNC rapid prototyping. With rapid prototyping technologies offering multiple pathways, a hybrid approach often provides the best results.

GID Company supports this balanced evaluation by offering clear estimates of time and cost across various prototyping paths. We help clients make informed trade-offs between speed and precision while leveraging advanced prototyping methods that reduce iteration cycles. Our localized facilities across Arizona, Georgia, and California provide the agility to meet regional market needs quickly and efficiently.

Material Considerations and Structural Behavior

The material selected for a prototype significantly influences which rapid prototyping technologies are most appropriate. If a prototype requires rubber-like flexibility or high thermal resistance, then additive manufacturing prototyping with specific resins or composites may be the best route. Conversely, metals and high-impact plastics may favor CNC rapid prototyping due to superior finish and structural integrity.

GID Company’s material expertise helps our clients navigate this complex decision space. We recommend the right materials based on performance needs, compliance standards, and post-processing requirements. Whether the prototype is produced through 3D printing for prototyping or more traditional milling methods, material behavior is a cornerstone of successful validation.

Risk Mitigation and Iteration Cycles

Prototyping is as much about reducing risks as it is about testing ideas. Choosing the wrong method can delay development, increase costs, and introduce reliability issues later in production. That’s why rapid prototyping technologies must be selected with risk profiles in mind—especially when developing safety-critical or regulated products.

At GID Company, we focus on compressing iteration cycles without sacrificing quality. Our decision framework incorporates functional testing, manufacturability assessments, and tolerance stack-ups to help clients refine their design with each round. This iterative mindset is made possible by advanced prototyping methods that emphasize flexibility, speed, and technical insight.

Matching Technology to Production Pathways

The ultimate goal of any prototype is to lead to a manufacturable, market-ready product. That’s why every prototyping decision should consider how closely the prototype matches the final production method. For instance, CNC rapid prototyping is often used to mirror injection-molded parts in early development, helping teams make more informed choices through rapid prototyping technologies.

GID Company aligns every prototype to its downstream manufacturing process. Whether the path involves casting, molding, or assembly-line production, we use 3D printing for prototyping and additive manufacturing prototyping as part of a phased strategy. This ensures that every step from concept to production is logically and efficiently connected.

Deployment, Scaling & U.S. Market Considerations

The journey from prototype to product doesn’t stop at validation—it must scale. For companies operating in competitive U.S. markets, the ability to move quickly from concept models to deployable solutions is a core advantage. Rapid prototyping technologies are only valuable if they can support this transition with consistency, flexibility, and quality. At GID Company, we focus on aligning each phase of development with market expectations, production standards, and logistical feasibility across regions like California, Texas, Georgia, and Arizona.

By combining 3D printing for prototyping, additive manufacturing prototyping, and CNC rapid prototyping into one seamless process, we ensure that scaling up doesn’t require starting over. Instead, we build from validated models and leverage advanced prototyping methods to prepare for real-world deployment.

Regional Infrastructure and Distributed Capabilities

As U.S. markets demand faster responses and localized production, having distributed prototyping infrastructure becomes essential. GID Company has strategically positioned its operations to serve major innovation hubs and manufacturing centers across the country. This proximity reduces shipping delays, supports in-person collaboration, and improves turnaround times for urgent projects.

Our facilities are equipped to deliver all forms of rapid prototyping technologies, from 3D printing for prototyping to CNC rapid prototyping, under one roof. This setup allows us to execute hybrid builds and rapid modifications based on market-specific feedback, giving clients the agility they need to respond quickly to new opportunities or challenges.

Quality Assurance in Rapid Prototyping Transitions

Scaling up from prototype to production involves more than just increasing volume—it requires maintaining quality and consistency at every stage. This is where our use of advanced prototyping methods plays a critical role. We embed quality control mechanisms throughout our workflow to ensure every stage of rapid prototyping technologies maintains precision and repeatability.

At GID Company, quality assurance is embedded into both additive manufacturing prototyping and CNC rapid prototyping phases. Using real-time measurement tools, material verification, and functional testing, we prepare each prototype to transition smoothly into the next phase of development. This consistency is critical when preparing for regulatory approvals, user trials, or investor demonstrations.

Cost Optimization for Scalable Prototyping

One of the key advantages of working with rapid prototyping technologies is cost control—especially when scalability is part of the equation. By optimizing material use, reducing tooling investments, and minimizing waste, businesses can avoid the high upfront costs that often delay product launches.

GID Company brings these advantages to every client project. Whether using 3D printing for prototyping or transitioning to additive manufacturing prototyping for pre-production runs, we apply lean practices to control costs without sacrificing speed or quality. This allows businesses to iterate more freely, test more thoroughly, and launch with greater confidence.

Regulatory Readiness and Compliance Considerations

Deploying prototypes into the U.S. market also involves regulatory and compliance standards, especially in sectors like healthcare, automotive, and consumer electronics. Rapid prototyping technologies must support not only functional testing but also documentation, traceability, and risk mitigation.

GID Company is experienced in aligning advanced prototyping methods with industry-specific regulatory requirements. From selecting FDA-compliant materials to producing dimensional inspection reports for safety-critical parts, we ensure that every stage of the prototyping process supports compliance and readiness. This alignment helps clients prepare for certification, scale-up, and market entry without unnecessary delays.

Bridging Prototyping and Production Through Smart Integration

The ultimate value of rapid prototyping technologies lies in their ability to connect seamlessly to manufacturing. This integration requires careful planning, technical fluency, and an understanding of how prototyping decisions affect downstream production.

At GID Company, we specialize in this transition. Our experts work closely with clients to identify which aspects of the prototype will carry into production and which require redesign. By utilizing a mix of CNC rapid prototyping, 3D printing for prototyping, and additive manufacturing prototyping, we create prototypes that evolve smoothly into final products. This continuous development model is supported by advanced prototyping methods that scale without compromise.

Future Outlook & Emerging Directions

As industries continue to push the boundaries of innovation, the landscape of rapid prototyping technologies is also evolving. What was once limited to basic mockups and form studies has now grown into a complex ecosystem of digitally-driven, production-ready methodologies. The future of prototyping lies in speed, intelligence, and scalability—and GID Company is actively investing in these shifts to serve the future needs of our clients across California, Florida, Utah, Texas, Arizona, and Georgia.

By harnessing developments in 3D printing for prototyping, additive manufacturing prototyping, CNC rapid prototyping, and other advanced prototyping methods, we are preparing our clients for a new era of product development defined by flexibility, automation, and smarter design feedback loops.

The Rise of 4D Printing and Smart Materials

One of the most anticipated advances within rapid prototyping technologies is the integration of smart materials and 4D printing. Unlike conventional prints, 4D prototypes are designed to react to external stimuli such as temperature, pressure, or moisture—opening possibilities for self-adjusting or shape-shifting components.

GID Company is monitoring this evolution closely. While 3D printing for prototyping has already enabled breakthroughs in design freedom, the emergence of dynamic, programmable materials will enhance functionality even further. Our team is actively testing the limits of what’s possible in this area through partnerships and in-house experimentation, preparing to offer solutions that support real-world adaptability and smarter mechanical responses.

AI-Driven Autonomous Design and Testing

Artificial intelligence is playing a greater role in design and prototyping by enabling systems that can autonomously generate, simulate, and optimize thousands of iterations in minutes. This will revolutionize how companies engage with rapid prototyping technologies, especially in high-stakes industries where time and accuracy are crucial.

At GID Company, we are investing in design automation tools that complement both additive manufacturing prototyping and CNC rapid prototyping workflows. This includes AI-powered topology optimization, generative design tools, and predictive simulation engines that reduce manual decision-making. These tools are integrated into our advanced prototyping methods to help clients reduce time-to-market while improving overall design integrity.

Microfactories and Distributed Manufacturing Models

The next generation of product development will rely heavily on microfactories—compact, automated production cells designed to build small batches of products on-demand. These agile units rely extensively on rapid prototyping technologies and will shift how companies think about production scale, logistics, and inventory.

GID Company is developing modular approaches to prototyping and manufacturing that mirror this trend. Our network of facilities across the U.S. allows us to deploy localized solutions that incorporate 3D printing for prototyping, CNC rapid prototyping, and additive manufacturing prototyping directly within our regional workflows. This distributed model reduces lead times, simplifies coordination, and enhances responsiveness to changing market conditions.

Democratization of Prototyping Tools for Startups

As advanced prototyping methods become more accessible, startups and independent innovators will gain greater access to tools that were once reserved for large corporations. This democratization will encourage broader innovation, but also place pressure on companies to develop more refined, market-ready prototypes from day one.

GID Company is adapting its service models to meet this shift. We are creating flexible engagement options for early-stage teams, offering scaled prototyping packages that leverage the full potential of rapid prototyping technologies without overwhelming budget constraints. From 3D printing for prototyping early visual models to using CNC rapid prototyping for functional testing, we help startups deliver polished results quickly and efficiently.

Preparing for the Next Decade of Prototyping Innovation

Looking ahead, the future of prototyping will depend on the convergence of software, hardware, and data-driven design thinking. As new materials emerge, software becomes smarter, and machines get faster, the role of rapid prototyping technologies will only expand. It will no longer be a stage in product development—it will become the engine that drives it.

At GID Company, our R&D teams are committed to exploring these frontiers. We continuously evolve our capabilities to include not only the most current forms of additive manufacturing prototyping and CNC rapid prototyping, but also the next generation of digital tools and fabrication strategies. Through ongoing investment and innovation, we prepare our clients for a future where every idea can move from sketch to prototype—and from prototype to market—at record speed.

Wrapping Up

The evolution of rapid prototyping technologies is more than a trend—it’s a transformative shift in how products are imagined, validated, and delivered. Across industries and throughout the U.S., businesses are embracing methods that make development faster, more accurate, and more agile. With tools like 3D printing for prototyping, CNC rapid prototyping, additive manufacturing prototyping, and other advanced prototyping methods, the possibilities for innovation are expanding daily.

GID Company has built its entire development framework around these advancements. Whether you’re creating a complex mechanical assembly, a smart consumer product, or a next-gen medical device, our team is equipped to support you from the first sketch through final validation. With regional facilities across California, Texas, Florida, Arizona, Georgia, and Utah, we provide localized service with national scalability.

Why Partner with GID Company

Our strength lies not only in the technologies we use but in how we apply them. We don’t just deliver prototypes—we deliver solutions. Every service we offer, from additive manufacturing prototyping to CNC rapid prototyping, is tailored to the specific needs of your project. Our experts bring deep technical knowledge, hands-on experience, and industry awareness to guide your product development toward success.

GID Company is ready to help you take the next step. Whether you’re launching a new product or refining an existing one, our integrated approach to rapid prototyping technologies ensures that every decision you make is a step toward better outcomes and faster market entry.