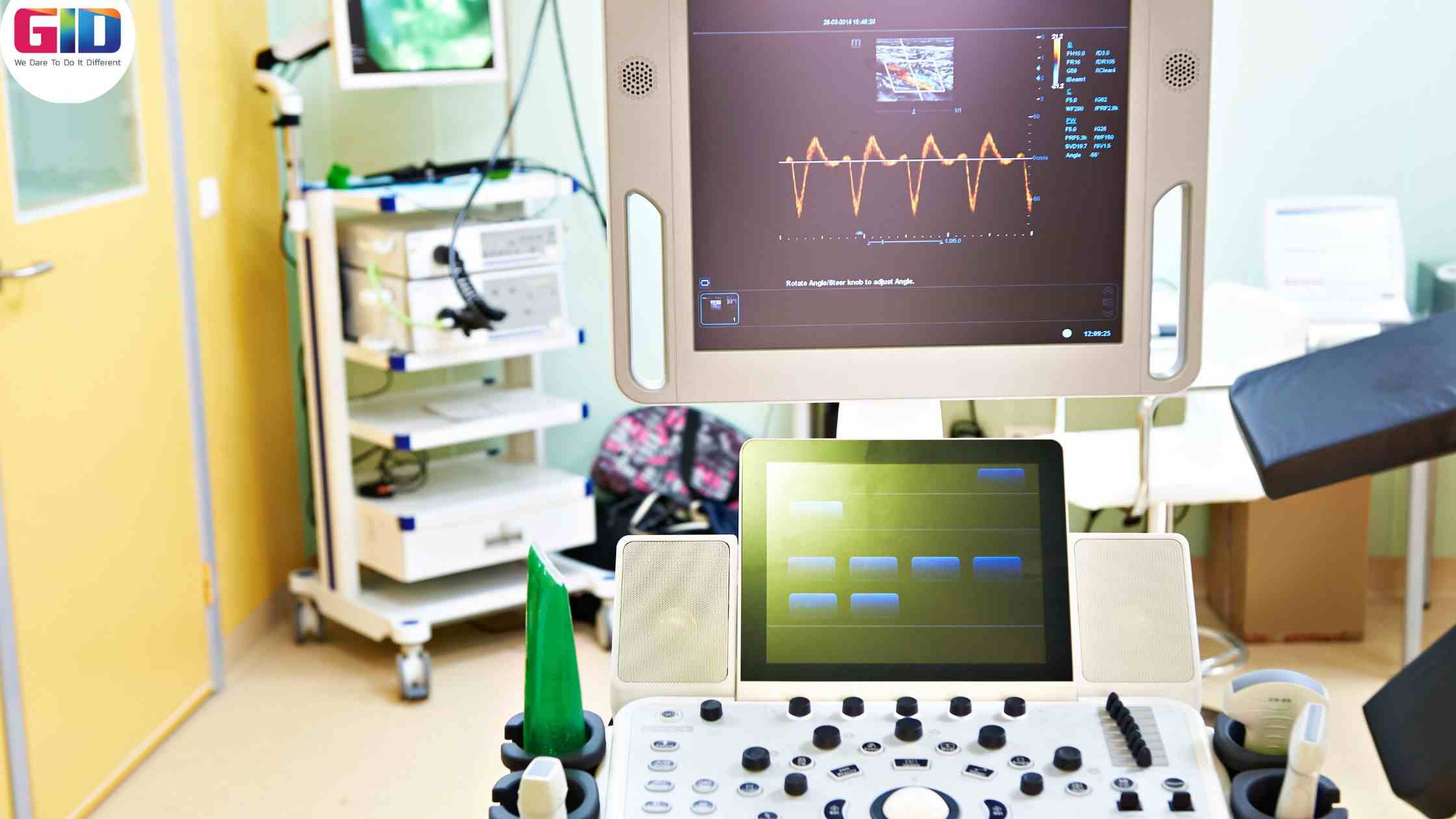

A medical device development company plays a critical role in transforming innovative healthcare ideas into real-world solutions, and GID Company is proud to lead the way in this specialized field. With a presence across key U.S. states like California, Texas, Florida, Arizona, Utah, and Georgia, we serve clients who demand speed, precision, and compliance.

At GID Company, our process begins where innovation meets execution. Whether you’re a healthcare startup in San Diego, a research team in Houston, or a clinical team in Orlando, our mission is simple: bring your medical device vision to life. We offer end-to-end solutions tailored to U.S. regulatory standards, market trends, and patient needs. By partnering with our multidisciplinary team, clients gain access to top-tier engineers, regulatory experts, and product strategists—all working together under one roof.

As a full-service medical device development company, we understand the stakes. Delays, compliance risks, or user-unfriendly designs can derail even the most promising concepts. That’s why GID Company applies a proven, regionalized approach that leverages in-depth knowledge of both national and state-level healthcare demands. Our success is grounded in structured methodologies and real collaboration, ensuring every medical device not only reaches the market—but thrives there.

Why a Medical Device Development Company Makes All the Difference

Choosing the right medical device development company is one of the most impactful decisions you’ll make in your product journey. The complexity of healthcare regulations, combined with the need for technical precision and market relevance, demands an expert partner. At GID Company, we don’t just offer services—we offer confidence.

Navigating the Regulatory Maze with Confidence

Medical devices must meet rigorous standards set by regulatory bodies like the FDA. These requirements vary not only by device classification but also by intended use and region of deployment. GID Company has deep experience guiding clients through the regulatory process, ensuring complete documentation and compliance at every phase.

Unlike generalized firms, a focused medical device development company understands the nuances of 21 CFR Part 820, ISO 13485, and risk management under ISO 14971. Our regulatory specialists work hand-in-hand with design and testing teams to ensure traceability and audit readiness from concept to launch. This collaboration minimizes delays and empowers you to enter markets like California, Texas, and beyond with certainty.

Reducing Risk through Expertise and Design Controls

Medical device development companies that lack embedded design controls can expose clients to costly errors. GID Company integrates detailed protocols early in the process to reduce these risks. From user need validation to human factor engineering, we make sure every requirement is not only documented but implemented and tested.

Our team emphasizes iterative design, employing verification and validation loops that adapt to both engineering outcomes and user feedback. Whether the device is meant for telemedicine applications in Florida or surgical use in Utah, every element is examined for safety, reliability, and user experience. This proactive approach has helped GID Company deliver market-ready solutions faster and with greater confidence.

Localized Expertise with a National Framework

GID Company stands apart from other medical device development companies by blending national-scale resources with local insights. We maintain operational strength across California’s innovation hubs, Arizona’s manufacturing sectors, and Georgia’s growing medtech network. This regional presence means faster turnaround times, localized usability testing, and face-to-face engagement—advantages that virtual-only models simply can’t match.

Our California team often collaborates with startups bringing novel diagnostics to market, while our Texas experts work closely with large-scale manufacturers to ensure design for manufacturability. This alignment between strategy, design, and execution ensures your medical device development firm partner remains agile, responsive, and fully invested in your success.

The GID Company Approach, Phase by Phase

At GID Company, our role as a medical device development company is defined by a clear, phased methodology that transforms ideas into compliant, market-ready products. Each stage is designed to eliminate uncertainty, reduce development timelines, and support the full product lifecycle. With expert teams positioned across California, Texas, Florida, Arizona, Utah, and Georgia, we offer unmatched regional depth combined with national capability.

Phase I – Concept and Feasibility

Every successful project begins with a strong foundation. As a medical device development company, GID Company engages in deep discovery work to validate the clinical need, target market, and technical feasibility. This stage is especially critical for startups and research teams located in innovation hubs like San Diego or Austin.

We start by gathering inputs from clinicians, engineers, and end users to define the real problem your device will solve. Using those insights, our team evaluates technical constraints, usability considerations, and preliminary risk factors. Feasibility prototypes are developed to test assumptions and identify early design directions. These early models are not only valuable for fundraising but also crucial for stakeholder feedback.

Medical device development companies often skip this depth of discovery, but GID Company ensures that no assumption goes untested. With risk analysis guided by ISO 14971 and early-stage input from regulatory specialists, we deliver a refined concept with a clear technical roadmap.

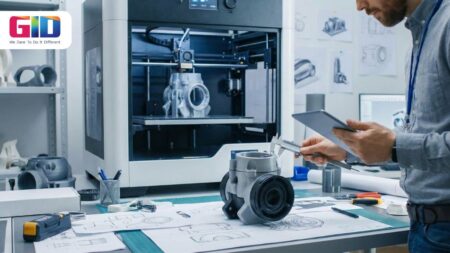

Phase II – Detailed Design and Verification

Once feasibility is established, our engineers enter the core design phase. This is where a concept becomes a device. GID Company develops complete design input requirements based on user needs, clinical environments, and regulatory expectations. This structured approach defines our role as a true medical device development firm.

In Texas and Arizona, where our engineering and manufacturing capabilities are based, our teams begin iterative prototyping. From engineering validation testing (EVT) to design validation testing (DVT), we assess mechanical, electrical, and software components for performance and durability. All work is guided by the FDA’s 21 CFR Part 820 and ISO 13485 standards, ensuring regulatory readiness from day one.

Design reviews occur at each milestone to evaluate safety, usability, and technical progress. We create design history files (DHF), device master records (DMR), and traceability matrices to map every decision and requirement. This integrated design control system is what differentiates a competent medical device development firm like GID Company from generalist providers.

Phase III – Validation and Regulatory Submission

With verified designs in hand, we shift to validation and compliance. This is the most scrutinized phase, and GID Company approaches it with precision. Clinical testing is managed in partnership with our network in Florida and Georgia, where access to diverse patient populations and research facilities accelerates study timelines.

We coordinate everything from protocol development to Institutional Review Board (IRB) submissions, ensuring ethical and regulatory alignment. Our documentation specialists prepare full submissions for FDA 510(k), De Novo, PMA, or CE Marking based on device classification and market goals. These regulatory packages include safety data, performance claims, labeling, and manufacturing processes.

Unlike many medical device development companies, GID Company provides support throughout agency interactions, responding to queries, and managing updates. This end-to-end guidance minimizes rejection risks and accelerates approvals, giving you a strong launch position in your intended market.

Phase IV – Manufacturing Transfer and Launch

Transitioning from prototype to production demands a new level of precision. GID Company applies design for manufacturability (DfM) and design for assembly (DfA) principles to ensure cost-efficiency, scalability, and quality in volume production. Our Arizona and Georgia facilities offer direct access to cleanroom assembly, component sourcing, and process validation.

We work with contract manufacturers and in-house teams to refine production workflows. Packaging design, labeling systems, and UDI compliance are all managed to meet domestic and global regulations. This streamlined launch preparation defines what clients expect from a trusted medical device development company.

In states like Texas and Florida, where healthcare markets are expanding, our launch strategies include technical training, logistics setup, and market entry planning. GID Company ensures your device not only ships on time but performs flawlessly in the field.

Phase V – Post-Market Surveillance and Lifecycle Support

Once your device reaches the market, the journey doesn’t end. Post-market responsibilities are critical to long-term success. As a forward-thinking medical device development firm, GID Company remains engaged through surveillance, feedback integration, and future product enhancements.

We develop complaint handling systems, adverse event reporting protocols, and CAPA plans that meet FDA and ISO expectations. Our teams in Utah and California work closely with users to gather performance data and identify opportunities for iteration. These insights inform not only product updates but also regulatory filings and competitive positioning.

Few medical device development companies maintain long-term engagement, but GID Company believes in building partnerships beyond the launch. Whether you’re enhancing software features, modifying components, or preparing next-gen versions, we stand by your side every step of the way.

How to Choose Among Medical Device Development Companies

When it comes to selecting a medical device development company, the decision can significantly impact both the success and the longevity of your product. With hundreds of firms claiming to offer end-to-end solutions, it’s essential to look beyond surface-level capabilities. GID Company provides a uniquely integrated approach, combining regulatory rigor, innovative design, and local engagement across California, Florida, Texas, Arizona, Utah, and Georgia.

Certification and Compliance Capabilities

Any reputable medical device development company must operate under internationally recognized standards. GID Company is fully certified under ISO 13485 and implements robust design control processes aligned with FDA 21 CFR 820. This ensures that every project is rooted in quality and compliance from the outset. We handle risk management under ISO 14971, biocompatibility planning using ISO 10993, and design verification protocols that meet global expectations.

Medical device development companies without these systems can inadvertently expose clients to compliance issues. GID Company avoids these pitfalls through proactive documentation, standardized internal audits, and continuous training across all teams.

Multidisciplinary Expertise and Regional Insight

What sets GID Company apart as a medical device development firm is the strength of our multidisciplinary team—spanning electrical engineering, mechanical design, software development, human factors, and regulatory affairs. More importantly, we embed these experts regionally. In California and Arizona, our engineers specialize in early-stage prototyping. In Texas and Georgia, we focus on scalable manufacturing solutions. This distributed model ensures rapid communication, shorter development cycles, and better local alignment.

Unlike generalized product firms, a dedicated medical device development company brings cross-functional fluency that integrates every part of the process—from concept validation in Utah to post-market reporting in Florida.

Flexibility in Engagement Models

Choosing the right partner also means finding a company that adapts to your specific needs. GID Company offers multiple engagement models, whether you’re looking for full lifecycle development or targeted support in design verification or regulatory strategy. This flexibility is critical for startups in California seeking investor-ready prototypes and for mature companies in Texas needing help with Class III PMA submissions.

Most medical device development companies are either too rigid or too scattered in their approach. GID Company delivers with structured agility, ensuring that your budget, timeline, and technical priorities remain central to the collaboration.

Working with a Medical Device Development Firm—The GID Company Way

The relationship between a client and a medical device development firm should be built on trust, transparency, and shared goals. At GID Company, our collaborative framework ensures you’re not just a customer—you’re a strategic partner. From day one, we work to deeply understand your clinical objectives, technical vision, and regulatory requirements.

Seamless Project Onboarding and Team Integration

When you begin working with GID Company, the onboarding phase is designed to get your project moving efficiently. We set up a clear governance structure that defines roles, responsibilities, and communication cadences. Whether you’re based in Florida or California, our kickoff meetings help clarify project scope, user personas, risk factors, and key milestones.

As a seasoned medical device development firm, we create alignment from the beginning by integrating our team with yours—whether in person or virtually—through structured sprint planning and joint documentation reviews.

Agile Development and Iterative Progress

We follow a hybrid-agile approach that blends medical device regulation with modern product development methodologies. GID Company’s sprint cycles include iterative prototyping, ongoing risk assessment, and regular stakeholder feedback. We maintain digital dashboards where your internal stakeholders can track progress, submit change requests, and review test results in real-time.

This process is what differentiates a responsive medical device development company from slower-moving traditional firms. By iterating weekly and validating continuously, we reduce both cost and development time.

Transparency and Decision-Making Tools

At every phase, GID Company emphasizes transparency. We provide tools like risk heat maps, requirements traceability matrices, and timeline visualizations. These tools allow our clients—whether they are in Arizona or Georgia—to make informed decisions quickly. Your leadership team always knows the status of technical progress, regulatory documentation, and manufacturing readiness.

Medical device development companies that operate in silos often keep clients in the dark until late-stage reviews. GID Company breaks down these walls, ensuring clear, two-way communication throughout the journey.

Wrapping Up

Partnering with a medical device development company is not just a tactical decision—it’s a strategic commitment to innovation, compliance, and market success. At GID Company, we offer more than just product development; we provide a complete innovation ecosystem tailored to the needs of today’s healthcare market. From our deep technical expertise to our regional teams across California, Texas, Florida, Arizona, Utah, and Georgia, we deliver value at every stage of your medical device’s lifecycle.

Supporting Innovation at Every Step

Whether you’re refining a concept or scaling a Class III product, GID Company brings clarity to complex processes. As a full-service medical device development firm, we reduce risk through proven methodologies, enhance speed-to-market with agile systems, and strengthen compliance through embedded regulatory oversight. Our clients benefit not only from our capabilities but also from our unwavering focus on patient safety, user experience, and long-term performance.

Start Your Medical Device Journey with Confidence

Choosing the right partner among many medical device development companies can be overwhelming, but GID Company removes the guesswork. We have the technical depth, operational infrastructure, and regional insight to support your product from concept through launch and beyond. If you’re looking for a medical device development company that operates with precision, transparency, and commitment, GID Company is ready to support your vision.