The moment usually comes quietly.

A prototype sits on the table. It works—mostly. The buttons respond. The form looks right. But something feels off. It doesn’t scale. It doesn’t feel manufacturable. And deep down, you know the next iteration could either unlock momentum or drain months of time and capital.

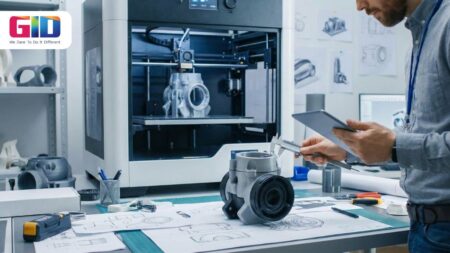

At GID Company, we see this moment often. Founders and product leaders across California, Texas, Florida, Arizona, Utah, and Georgia don’t come to us because they lack ideas. They come because innovation today moves faster than intuition alone can handle.

That’s where understanding why product design is changing—and how to apply those changes—becomes the difference between progress and frustration.

This is the story of how modern design thinking reshapes prototyping, and how we help teams turn uncertainty into buildable clarity.

Product design trends driving the next wave of prototypes

Not every trend deserves attention. Some are noise. Others quietly redefine how products survive contact with real users, real factories, and real budgets.

At GID Company, we treat product design trends as signals, not slogans. They tell us where risk hides and where leverage lives—especially during prototyping, when decisions compound fast.

AI-assisted design without losing human judgment

AI now accelerates early design exploration. Concepts evolve faster. Constraints surface sooner. But AI doesn’t understand user frustration, brand perception, or manufacturing nuance.

That’s why our approach blends machine speed with human decision-making. We use AI to expand options, then apply experience to narrow them into prototypes that make sense in the real world.

Sustainability built into the first sketch

Sustainability is no longer a finishing touch. It starts at material selection, part count, and assembly logic.

For teams designing in California or scaling manufacturing in Texas, this shift changes how prototypes are evaluated. At GID Company, we guide teams to design for reuse, repair, and efficiency early—before sustainability becomes an expensive retrofit.

Designing for real hands, not ideal users

Products don’t live in slide decks. They live in warehouses, hospitals, vehicles, and job sites.

Modern product design trends emphasize accessibility, usability, and edge cases. We design prototypes that account for gloves, glare, fatigue, vibration, and speed—so testing reveals truth, not surprises.

Immersive design reviews that reduce rework

AR and virtual walkthroughs now allow stakeholders to experience products before physical builds. This reduces misalignment and speeds decisions.

At GID Company, we use immersive review tools strategically—only where they meaningfully reduce prototype cycles and cost.

Product development trends reshaping how teams build

Innovation used to move in a straight line. Today, it loops, overlaps, and accelerates.

These product development trends demand tighter integration between design, engineering, and manufacturing from day one.

Cross-functional collaboration replaces handoffs

Siloed workflows delay truth. Modern development favors small, integrated teams that solve problems together.

At GID Company, our process intentionally blends disciplines early, so prototypes don’t collapse under manufacturing realities later.

Data continuity becomes non-negotiable

Every prototype now feeds the next phase. Decisions must be traceable. Assumptions must be visible.

We help teams build a digital thread that carries intent from concept through prototyping and into production readiness—especially critical for distributed teams across Florida, Georgia, and the Southwest.

Recent trends in manufacturing influencing prototyping

Manufacturing constraints no longer wait politely at the end of development.

These recent trends in manufacturing shape prototypes almost immediately.

Manufacturing readiness starts earlier

Automation, traceability, and quality expectations push production thinking upstream.

At GID Company, we design prototypes with manufacturing behavior in mind, not just form and function. That foresight prevents costly redesigns later.

Simulation complements—but never replaces—physical testing

Digital twins and simulations reduce risk, but physical prototypes still reveal human and environmental realities.

We balance both, helping teams choose the right validation method at the right moment.

Latest trends in product design accelerating innovation

Speed alone doesn’t create innovation. Direction does.

The latest trends in product design focus on flexibility, experience, and controlled iteration.

Modular design enables smarter pivots

Modularity allows teams to adapt without starting over.

We help clients structure prototypes so changes are strategic, not disruptive.

Experience-first thinking guides technical choices

A product can work perfectly and still fail.

At GID Company, we design prototypes that prove desirability alongside feasibility—so innovation resonates, not just functions.

How GID Company turns trends into build-ready prototypes

This is where insight becomes action.

Our approach isn’t about following trends. It’s about translating product design trends into decisions that survive reality.

We guide teams through:

- Signal filtering: identifying which trends apply to your product

- Prototype strategy: deciding what to validate now versus later

- Real-world testing: aligning validation with actual use conditions

- Manufacturing readiness: preparing designs for smooth handoff

This is how uncertainty becomes momentum.

Wrapping Up: From Idea to Something That Holds Up

Every product journey reaches a turning point—the moment when a prototype stops being fragile and starts being credible.

That moment doesn’t come from trends alone. It comes from applying them with discipline, experience, and intent.

At GID Company, we help teams across California, Texas, Florida, Arizona, Utah, and Georgia move past guesswork and into confident execution—turning innovation into something you can actually build.