It usually starts quietly. A half-folded notebook. A rough sketch on the back of a receipt. A thought that keeps circling your mind long after the day ends. You can see the product clearly, but you can’t yet touch it.

That moment is familiar to inventors everywhere—from small home workshops in Texas, to startup garages in California, to late-night idea sessions in Florida, Arizona, Georgia, and Utah. The excitement is real. So is the uncertainty.

At GID Company, we meet inventors and entrepreneurs right at that crossroads. Not when the product is perfect—but when it’s still fragile. When the biggest question isn’t how to sell it, but how to build the right first version. That’s where smart prototyping changes everything.

Rapid prototyping services: Your fastest path from “What if?” to “It works”

Rapid prototyping services exist for one reason: to turn uncertainty into clarity as fast as possible. Not by guessing. Not by over-engineering. But by building, testing, learning, and refining with intention.

At GID Company, we don’t treat prototypes as finished products. We treat them as answers. Each prototype is designed to resolve a specific question—about size, strength, usability, or feasibility—before you invest further time or money.

For inventors across California, Texas, Florida, Arizona, Georgia, and Utah, our role isn’t just to fabricate parts. It’s to guide decisions. We help you move from imagination to evidence, without losing momentum or control of your idea.

Act One – The challenge: When rapid prototyping goes wrong

The “looks good, doesn’t work” problem

One of the most common mistakes in rapid prototyping is building something that looks impressive but tells you very little. Smooth surfaces. Perfect symmetry. Zero insight into how the product behaves under real conditions.

Without guidance, inventors often spend early budgets creating prototypes that impress visually but fail functionally. That kind of misstep can stall progress before momentum ever builds.

The endless iteration spiral

Another trap is changing too much, too often. When rapid prototyping lacks structure, every revision feels urgent. Features pile up. Costs rise. Confidence drops.

Rapid prototyping should reduce risk—not multiply it.

Too many vendors, no clear owner

Inventors searching for help in rapid prototyping services near me often discover a fragmented process. One shop prints parts. Another tweaks CAD. Someone else gives advice—but no one owns the outcome.

At GID Company, we eliminate that fragmentation by acting as the single point of accountability from concept through iteration.

Act Two – The insight: Choosing the right prototype for the right moment

Not every prototype needs to do everything. That’s the insight most inventors discover too late.

Early-stage prototypes

These focus on form, scale, and basic interaction. They answer questions like:

- Does it fit the user’s hand?

- Does the size feel right?

- Does the concept translate physically?

Functional prototypes

At this stage, materials, strength, and movement matter. These builds test stress points, tolerances, and mechanical behavior.

Pre-production prototypes

These prepare your product for manufacturing reality. They account for assembly, repeatability, and production constraints.

GID Company helps inventors sequence these stages properly, so rapid prototyping always moves forward—never sideways.

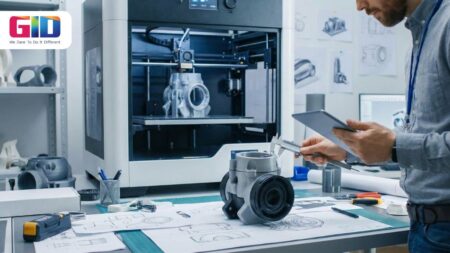

Rapid prototyping 3D printing: Powerful, but not magic

Rapid prototyping 3D printing has transformed how fast ideas can become physical. But speed alone doesn’t guarantee progress.

Where 3D printing shines

- Fast geometry changes

- Ergonomic testing

- Concept validation

Where it falls short

- High-load mechanical performance

- Heat or chemical exposure

- Tight tolerance assemblies

That’s why GID Company never treats printing as the goal. We use it as a tool—one that fits into a broader prototyping strategy aligned with your product’s future.

Rapid prototyping services near me: Why proximity still matters

When inventors search for rapid prototyping services near me, they’re really searching for responsiveness. Clarity. Speed of feedback.

Whether you’re based in California, Texas, Florida, Arizona, Georgia, or Utah, GID Company supports tight iteration cycles through structured reviews, clear testing criteria, and real collaboration.

Near doesn’t just mean physical distance. It means being close to your goals, your timeline, and your constraints.

Professional rapid prototyping services: What “professional” really means

Professional rapid prototyping services aren’t defined by machines. They’re defined by process.

At GID Company, professionalism shows up as:

- Clearly defined prototype objectives

- Documented iteration logic

- Material and process justification

- Early awareness of manufacturing realities

Every prototype exists for a reason. Every revision has a purpose.

Product designer near me: Why design thinking belongs in prototyping

Searching for a product designer near me isn’t about aesthetics alone. Good design determines how a product is used, understood, and trusted.

A prototype without design thinking often leads to costly revisions later. GID Company integrates product design and engineering early, so your prototype reflects both human behavior and technical reality.

That balance is what turns a prototype into a product foundation.

Act Three – Resolution: Holding the first version that answers real questions

There’s a moment every inventor remembers. The first time the prototype doesn’t just exist—but explains itself.

You don’t just see it. You understand what works, what doesn’t, and what comes next. That clarity is the real outcome of rapid prototyping services done right.

GID Company exists to make that moment arrive sooner—and with fewer missteps.

Wrapping Up: Build fast, learn faster, and move forward with confidence

Inventing is never linear. But progress doesn’t have to be chaotic. With the right rapid prototyping services, each step builds confidence instead of doubt.

Whether you’re developing your idea in California, Texas, Florida, Arizona, Georgia, or Utah, GID Company helps transform early concepts into tested, informed prototypes—ready for what comes next.