Get Product Prototype Developed is a crucial step in new product development. Simply put, a product prototype is a physical version of your concept that you can see, touch, and feel. Get Product Prototype Developed to gain several key advantages. First, by getting a product prototype developed, you’ll be able to visualize and experience how your final product will turn out. Second, getting a product prototype developed can help attract stakeholders who may finance your new product for mass production. Finally, get product prototype developed to test and refine your idea before moving on to large-scale manufacturing.

When it comes to new product development, various complications can emerge, many of which won’t become apparent until you get product prototype developed. Thus, getting a product prototype developed is essential. Fortunately, you don’t have to handle this process on your own. Many product prototype development companies can help you get product prototype developed accurately, quickly, and cost-effectively. Here are a few steps to guide you on how to get product prototype developed swiftly.

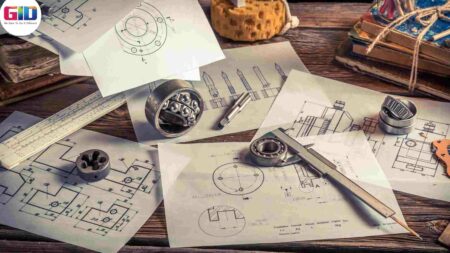

- To get product prototype developed, start by creating a rough sketch of your innovation, followed by a more detailed drawing. You can either draw these sketches yourself using pencil and paper or enlist someone to sketch your idea based on your description. Once your rough sketches are complete, you need to get detailed CAD drawings made. If you’re familiar with CAD applications, you can create these drawings yourself. If not, you’ll need to hire someone to help. These CAD drawings are essential for effectively communicating your concept to the company responsible for getting your product prototype developed.

- Find a product prototype development company that can develop a good prototype based on your requirements and CAD drawings. If your innovation is supposed to be made from metal, then find a prototype development company that specializes in making metal prototypes. If your innovation is supposed to be made from plastic, approach a company that specializes in plastic product manufacturing or rapid prototyping. Revolutionary rapid prototyping is capable of getting your product prototype ready fairly swiftly.

- To get product prototype developed to perfection, you may need to redevelop it multiple times to achieve the ideal construction and function. It’s rare to get product prototype developed perfectly on the first attempt. Typically, several iterations are required to refine the prototype. While advanced technologies, such as Dassault Systèmes’ 3DEXPERIENCE platform, including CATIA V6, SOLIDWORKS, 3DVIA, and 3DEXCITE, can assist in creating a precise prototype, multiple versions of the prototype will likely still need to be developed. This redevelopment process might be necessary not only due to functional or structural requirements but also to incorporate valuable feedback from potential customers.

- Get the Product Prototype Developed and proceed to mass-produce the final prototype, then introduce your idea to potential customers. When you get product prototype developed, it allows you to identify and eliminate any flaws in your design. Once you have the final product prototype—flawlessly constructed and functional—you’ll be assured that your final product is free from issues. With confidence in your prototype’s quality, you can move forward with mass production and market your product to potential consumers.

Need help with product prototype development? Get in touch with GID Company. A leading product design and product development company in California, USA, GID Company provides A to Z product fulfillment services, including new product prototype development and mass manufacturing. To learn more about GID Company.

How to Get Product Prototype Developed: A Step-by-Step Guide

Are you eager to turn your innovative idea into a tangible prototype? Here’s a step-by-step guide to help you navigate the process of getting a prototype made.

- Conceptualize Your Idea: Begin by thoroughly outlining your concept, and specifying key features, materials, and functionality. The clearer your vision, the smoother the prototyping process will be.

- Choose the Right Prototype Development Partner: Select a reputable product development company like GID Company with a proven track record in creating prototypes. Research and verify their expertise and past projects.

- Initial Consultation: Schedule a consultation with your chosen prototype development team. Discuss your concept, objectives, and budget. A professional team can provide insights and suggest improvements.

- Design and Development: Work closely with the experts to create a detailed design of your prototype. This phase includes selecting components, creating schematics, and developing a blueprint.

- Prototyping: Once the design is finalized, your chosen partner will create a physical prototype. This may involve 3D printing, CNC machining, or other fabrication methods, depending on the complexity of your product.

- Testing and Refinement: Thoroughly test the prototype to identify any issues or areas for improvement. Collaborate with the development team to refine the design based on test results.

- Cost Analysis: Assess the cost of producing the prototype. This evaluation helps you determine if any adjustments are needed to fit your budget.

- Manufacturing Feasibility: Determine whether the prototype can be manufactured cost-effectively at scale. Your development partner can assist in this analysis.

- Regulatory Compliance: If your product falls under specific regulations or standards, ensure that the prototype meets these requirements.

- Market Validation: Gather feedback from potential users or investors to validate your prototype’s market potential.

- Next Steps: Depending on your goals, you can proceed to seek investors, launch a crowdfunding campaign, or move forward with mass production.

- Continuous Collaboration: Maintain open communication with your prototype development team throughout the process. Their expertise is invaluable in ensuring your prototype aligns with your vision.

Getting a prototype made is a dynamic and collaborative process, and selecting the right partner to help you get product prototype developed, such as GID Company, can be crucial. When you get a product prototype developed with dedication, creativity, and technical expertise, your idea can be transformed into a functional prototype.

Read Also: Important Points to Remember During Product Prototype Development

Conclusion

If you are an Inventor, a Startup, or an Established Company that wants to turn your product idea into a profitable market-ready product then contact GID Company today!

As a leading Industrial Product Design and Development Company, we serve different industries and offer the best services for Electronic Product Design, IoT Product Design, Life Safety Product Design, Medical Device Design, and Mechanical Design.

You can also follow our blog to stay updated with the latest trends related to product design and development. Feel free to Contact Us or call us at +1714-323-1052. You can also like our Facebook page and follow us on Instagram to get interesting product design and development news on your timeline.