In today’s fast-paced product development landscape, speed and innovation are critical for staying ahead of the competition. Whether you’re a startup refining your first concept or a large company pushing boundaries, the ability to transform ideas into tangible models quickly is key to success. This is where rapid prototyping comes in—a cutting-edge process that allows designers and innovators to bring concepts to life faster than ever before.

At GID Company, we understand that turning a vision into reality can be daunting. That’s why our prototyping services are designed to help you create, test, and perfect your product efficiently. With decades of experience, we provide customized prototyping solutions tailored to your unique needs, no matter where you’re based—from California to Texas, Florida, or beyond.

What is Rapid Prototyping?

Rapid Prototyping Definition

At its core, prototyping is a collection of techniques used to quickly fabricate a scale model or physical part of a design using 3D CAD (Computer-Aided Design) data. Unlike traditional prototyping methods, which can take weeks or even months, prototyping drastically reduces the time needed to produce a working model. This speed allows for faster iterations, testing, and feedback, making it an essential part of modern product development.

The rapid prototyping definition may sound technical, but its value is clear: it helps you see your design in action, test it in real-world conditions, and make necessary adjustments—all without committing to full-scale production. Whether you’re developing a medical device, consumer gadget, or industrial tool, fast prototyping can save you time, money, and headaches.

Why Prototyping Matters

For product designers and innovators, the ability to quickly produce a prototype offers immense benefits:

- Faster Time to Market: In industries where timing is everything, rapid prototyping services help companies get their products to market faster by allowing for rapid iterations.

- Cost-Efficient Testing: Building a prototype early on enables designers to test the functionality and usability of their design, reducing the risk of costly mistakes down the line.

- Improved Communication: Physical models enhance communication between team members, stakeholders, and potential investors, providing a clear vision of the product.

By using prototyping, companies can innovate faster and stay ahead in competitive markets.

GID Company’s Approach to Rapid Prototyping

At GID Company, we pride ourselves on being one of the leading rapid prototyping companies in the USA, with a strong presence in Southern states like California, Texas, and Florida. Our team understands the challenges product designers face, and we offer tailored solutions that fit the unique needs of each client.

With GID Company’s prototyping services, you can expect:

- Precision and Speed: Whether you’re looking for fast rapid prototyping for a consumer product or a highly detailed model for industrial use, we have the expertise and technology to meet your goals.

- Versatile Materials and Methods: We work with a variety of materials and techniques, ensuring that your prototype performs as expected under real-world conditions.

The Rapid Prototyping Process – How It Works

Understanding the prototyping process can help you see how quickly and efficiently a concept can be transformed into a functional prototype. At GID Company, we streamline each step, from initial design to final testing, ensuring you get the results you need—fast. Let’s break down how our prototyping services work and how they can benefit your product development journey.

Conceptualization – Turning Ideas Into Reality

The first step in rapid prototyping is the conceptualization phase. This is where your ideas take form. At GID Company, we work closely with you to fully understand your vision. Whether you have detailed sketches or just a rough concept, our team uses the latest design tools, including CAD (Computer-Aided Design) software, to bring your ideas to life.

In this stage, it’s essential to create a design that not only looks good but also functions well. The flexibility of prototyping allows designers to make adjustments early on, without committing to final materials or manufacturing processes. This is crucial for avoiding costly revisions down the road.

With fast rapid prototyping, you can quickly visualize your product and share it with stakeholders, clients, or investors, enabling effective communication and early feedback.

Design – Crafting Your Digital Model

Once your idea has been conceptualized, it’s time to translate that vision into a digital model. Using advanced CAD software, our designers create highly detailed and accurate representations of your product. These digital models are the blueprint for the rapid prototyping process, providing a precise guide for the prototype’s fabrication.

At GID Company, we don’t just stop at creating a model. We analyze the design for functionality, usability, and manufacturability, ensuring the prototype will perform as expected. This stage allows us to identify any potential issues before they become problems in production.

This is where the true value of prototyping comes into play. Unlike traditional methods, which may require significant time and resources to test a design, prototyping services allow for multiple iterations in a short period. If changes are needed, they can be made quickly, ensuring your final design is optimized for performance.

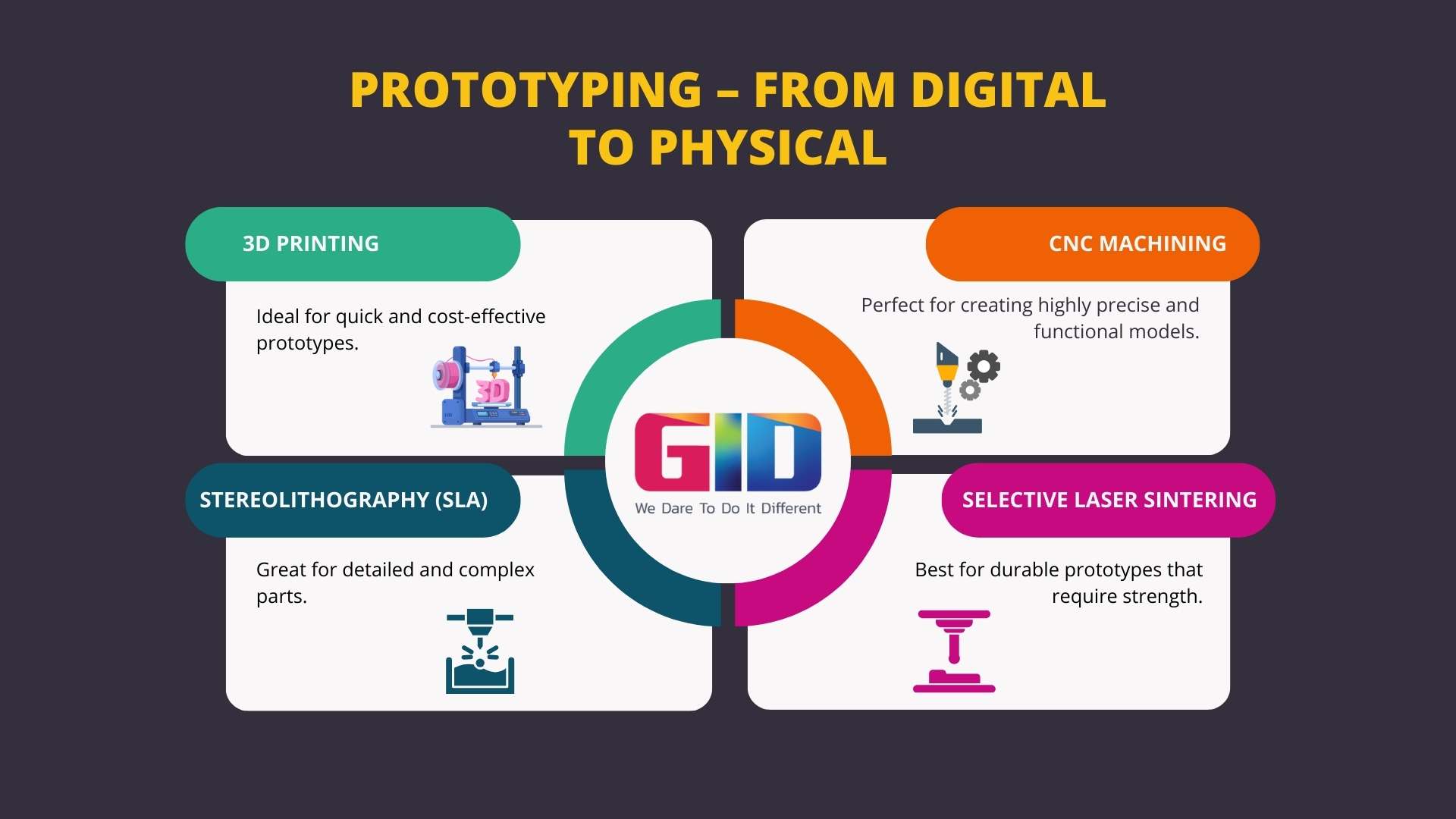

Prototyping – From Digital to Physical

After the design is finalized, we move into the heart of the rapid prototyping process—fabrication. This is where your digital model is transformed into a physical prototype. Depending on your project, we use a range of techniques, including:

- 3D Printing: Ideal for quick and cost-effective prototypes.

- CNC Machining: Perfect for creating highly precise and functional models.

- Stereolithography (SLA): Great for detailed and complex parts.

- Selective Laser Sintering (SLS): Best for durable prototypes that require strength.

Each method offers its own advantages, and at GID Company, we tailor our prototyping services to suit the specific needs of your project. Whether you need a prototype for testing form, fit, or function, we have the tools and expertise to get it done.

Our approach ensures fast prototyping without compromising on quality. We know that time is critical, especially for product designers working on tight schedules. With locations in key innovation hubs like California, Texas, and Florida, we provide quick turnaround times for clients nationwide.

Testing & Feedback – Perfecting the Prototype

The final stage of the rapid prototyping process is where your prototype is put to the test. This is where you get to see how your product performs in real-world conditions. At GID Company, we encourage our clients to rigorously test their prototypes, gathering crucial feedback on functionality, usability, and overall design.

Rapid testing allows you to make refinements quickly. Unlike traditional prototyping methods, where adjustments could take weeks or months, prototyping allows you to modify and improve your design in a fraction of the time.

At GID Company, we work alongside you during this stage to implement any necessary changes, ensuring your prototype meets your exact specifications. This collaborative approach is one of the reasons why we’re among the top rapid prototyping companies in the industry.

Read Also: Important Points To Consider For New Product Development

Different Types of Rapid Prototyping

There are various techniques used in prototyping, each suited to different applications. Choosing the right method depends on your project’s specific requirements, such as material, complexity, and function. Below, we explore four common types of prototyping services and how they are used.

3D Printing – Fast and Cost-Effective

One of the most well-known types of rapid prototyping is 3D printing. This method is ideal for creating prototypes quickly and at a low cost. 3D printing works by building a part layer by layer, using materials such as plastic, resin, or metal.

At GID Company, we use 3D printing to deliver fast prototyping, ensuring you can test your design without waiting weeks for a prototype. While 3D printing is excellent for concept models and low-cost prototypes, it may not always be suitable for high-precision parts. However, for most design validation processes, it’s an invaluable tool.

CNC Machining – High Precision for Functional Parts

For projects that require high accuracy and durability, CNC machining is often the best choice. This process involves cutting away material from a solid block to create the prototype. It’s ideal for producing fully functional parts that can be tested for fit, form, and function.

GID Company’s rapid prototyping services include CNC machining, which allows us to create prototypes with tight tolerances and high levels of detail. This method is perfect for industries like automotive, aerospace, and medical, where precision is critical.

Stereolithography (SLA) – Intricate and Detailed Prototypes

When you need complex or highly detailed prototypes, Stereolithography (SLA) is a great option. SLA uses a laser to cure liquid resin into solid shapes, layer by layer. This process is known for producing smooth and intricate parts that look highly polished.

At GID Company, we utilize SLA for prototypes that require fine details or intricate geometries. This method is particularly useful for industries like jewelry design, consumer electronics, and medical devices, where aesthetics and detail are essential.

Selective Laser Sintering (SLS) – Durable and Functional Prototypes

Selective Laser Sintering (SLS) is another popular technique in rapid prototyping. It uses a laser to fuse powdered material into a solid structure. SLS is ideal for creating strong, durable prototypes that can withstand rigorous testing.

GID Company’s expertise in SLS ensures that you receive prototypes that not only look good but can also handle real-world conditions. This is especially important for industries where products must undergo extensive testing before hitting the market.

Rapid Prototyping Services at GID Company – How We Help You Innovate

When you’re looking for rapid prototyping services, finding a partner that understands both your vision and your timeline is critical. At GID Company, we specialize in offering fast prototyping solutions that cater to businesses across various industries, from startups to large enterprises. Our goal is to help you move from concept to reality in the shortest possible time, without sacrificing quality or precision.

Why Choose GID Company for Rapid Prototyping?

There are many rapid prototyping companies out there, but GID Company stands apart for several key reasons:

- Speed: Time is often the biggest factor in product development, and we understand that delays can cost you both time and market share. That’s why we focus on providing fast prototyping, with a streamlined process that delivers accurate prototypes quickly.

- Quality: Speed is nothing without precision. At GID Company, our prototyping services ensure high-quality prototypes that meet your specifications exactly. We use advanced technologies like CNC machining, 3D printing, SLA, and SLS to create models that are both functional and durable.

- Customization: Every project is different, and a one-size-fits-all approach just doesn’t work. GID Company offers tailored solutions to meet the unique requirements of your product, whether you need a simple model for concept validation or a fully functional prototype for testing.

Our team of experts works closely with you to understand your product goals and create a customized prototyping plan. With our locations in innovation hubs like California, Texas, Florida, and other key Southern states, we’re positioned to serve clients nationwide with prototyping services that fit their specific needs.

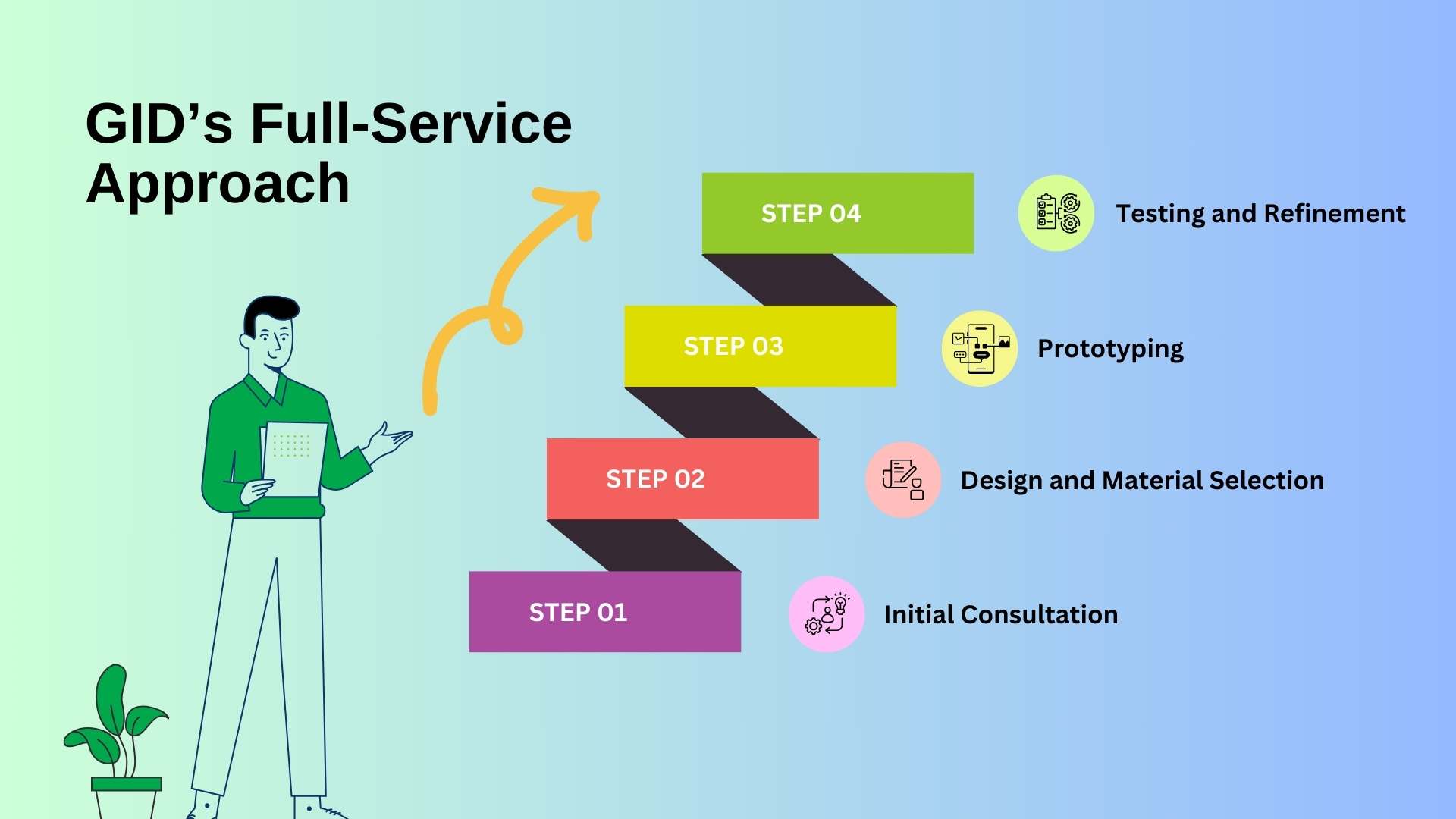

GID Company’s Full-Service Approach

At GID Company, we don’t just focus on the technical aspects of rapid prototyping; we also prioritize your overall experience. From the moment you engage with us, we take a consultative approach to ensure your project is successful.

Our full-service offering includes:

- Initial Consultation: We start by understanding your vision and requirements. Whether you have a fully developed design or need help refining your concept, our team is ready to assist.

- Design and Material Selection: Once we’ve defined your project goals, we help you choose the best design approach and materials to ensure a prototype that’s both cost-effective and functional.

- Prototyping: We use the most appropriate prototyping methods for your project, ensuring a quick turnaround without compromising on quality.

- Testing and Refinement: After your prototype is created, we assist you in testing and refining the model, making necessary adjustments to ensure it meets all functional and aesthetic requirements.

Whether you’re based in California, Texas, or Florida, our prototyping services are designed to help you achieve fast, reliable results that drive innovation.

How Rapid Prototyping Fuels Innovation in AI and UX Design

While prototyping is often associated with physical products, its applications extend far beyond traditional industries. In fields like artificial intelligence (AI) and user experience (UX) design, prototyping services play a critical role in driving innovation. By enabling designers and developers to test and iterate quickly, rapid prototyping helps push the boundaries of what’s possible in these cutting-edge sectors.

What is Rapid Prototyping in AI?

In the realm of AI, prototyping allows developers to create and test algorithms, machine learning models, and hardware components in a real-world environment. The ability to quickly build and refine AI-driven systems is crucial for ensuring that the technology works as intended. Whether it’s creating a prototype for a new AI-powered sensor or testing a neural network, rapid prototyping accelerates the development process.

At GID Company, we work closely with AI innovators to provide fast prototyping solutions that meet the specific demands of this rapidly evolving field. Our experience in creating high-precision prototypes ensures that AI products can be tested and optimized in record time, helping developers stay ahead of the curve.

What is Rapid Prototyping in UX Design?

Rapid prototyping is equally important in UX design, where user interaction and experience are critical. Designers use prototyping to quickly create mockups and interactive models of user interfaces. This allows them to test usability, get real-time feedback, and make iterative changes based on user input.

The iterative nature of prototyping in UX design means that developers can refine their designs without having to start from scratch. This process is particularly valuable when creating user-centered products, where small changes in design can significantly improve the user experience.

At GID Company, we support UX designers by providing prototyping services that turn digital concepts into physical or interactive models. Whether you need a quick mockup of a product interface or a detailed prototype for user testing, our team can help you create models that reflect your design vision.

The GID Company Advantage for AI and UX Designers

For AI and UX projects, fast prototyping is essential for innovation. At GID Company, we offer the speed, precision, and customization needed to support these high-tech fields. Whether you’re refining an AI system or perfecting a user interface, our rapid prototyping services give you the tools to iterate quickly and get to market faster.

By partnering with GID Company, AI developers and UX designers gain access to:

- High-Quality Prototypes: Our prototypes allow you to test functionality and usability in real-world scenarios.

- Customization: We tailor our services to meet the unique needs of AI and UX projects.

- Fast Turnaround: Our fast prototyping ensures you can iterate and refine your designs quickly, keeping you ahead in competitive markets.

Why Choose GID Company Over Other Rapid Prototyping Companies?

With so many prototyping companies to choose from, it can be difficult to find the right partner. What sets GID Company apart is our combination of technical expertise, customer-centric approach, and the ability to offer fast rapid prototyping without sacrificing quality. Whether you’re a product designer in California or an innovator in Texas, we’re committed to helping you bring your vision to life.

Expertise Across Industries

GID Company has decades of experience providing prototyping services to a wide range of industries, including:

- Medical Devices: We produce high-precision prototypes for surgical tools, diagnostic devices, and more.

- Consumer Products: From electronics to household items, we help companies validate designs quickly.

- Automotive and Aerospace: Our durable prototypes meet the stringent requirements of these industries, ensuring safety and functionality.

Each industry has its own set of challenges, but our experience allows us to tailor our prototyping approach to meet your specific needs. Whether you’re looking for fast prototyping for a simple gadget or a complex machine, GID Company delivers results.

State-of-the-Art Technology

What makes GID Company one of the top rapid prototyping companies is our use of cutting-edge technology. From 3D printing to CNC machining, we invest in the latest tools and equipment to ensure the highest quality prototypes.

Our facilities in California, Texas, Florida, and beyond are equipped with advanced machinery capable of producing intricate, high-precision models. This technology allows us to provide prototyping services that are faster, more accurate, and more cost-effective than traditional methods.

Collaborative Customer Support

At GID Company, we believe that the success of any project depends on clear communication and collaboration. We don’t just deliver prototypes; we partner with you throughout the process, providing ongoing feedback and adjustments as needed.

Whether you need help with material selection or require multiple iterations to perfect your design, our team is here to support you. This customer-first approach has helped GID build a reputation as one of the most reliable prototyping companies in the Southern United States.

Conclusion

Rapid prototyping is an invaluable tool for product designers and innovators, allowing for faster development, more efficient testing, and improved communication between teams and stakeholders. At GID Company, we specialize in delivering fast prototyping solutions that meet your project’s unique needs—whether you’re working in AI, UX design, or any other industry.

With our state-of-the-art facilities and experienced team, we provide the best rapid prototyping services across Southern states like California, Texas, Florida, and beyond. Our commitment to quality, speed, and customer collaboration makes us one of the leading rapid prototyping companies in the United States.

Ready to bring your product ideas to life? Contact GID Company today to learn more about our services and how we can help you innovate faster.