Comprehensive Product Development Services

From Leading Product Develpment Company in California, USA

From concept ideation and product designing to prototyping and manufacturing support, our services guide your product through every stage of development. We tailor solutions to your specific needs, ensuring your vision is brought to life with efficiency and expertise.

From Idea to Reality - Watch How We Do It!

Our Process: A Roadmap to Your Product's Success

Partner with expert Product Development Agency in California, USA

-

Discovery

-

Ideation

-

Concept Development

-

Feasibility Analysis

-

Design & Engineering

-

Prototyping

-

Testing & Validation

-

Refinement

-

Manufacturing

-

Marketing & Launch

-

Post-Launch Evaluation

-

Ongoing Support

Our Areas of Expertise - GID Company

Expert Product Development Solutions

GID Company's diverse team of experts brings a wealth of experience across a wide range of product development disciplines. We specialize in crafting innovative solutions that cater to your unique industry and product needs.

Our core areas of expertise include:

Why Choose GID Company to Partner with?

Experience - Expertise - Dedication

Partnering with GID brings decades of expertise, a streamlined product development process, and a dedicated team focused on your success. Here's what you can expect when you choose GID:

Proven Product Development Expertise

Benefit from 20+ years of industry experience and technical expertise in product development, ensuring high-quality outcomes for every project.

End-to-End Product Development Solutions

GID Company offers comprehensive services from concept to market launch, providing a seamless development process with a single point of contact.

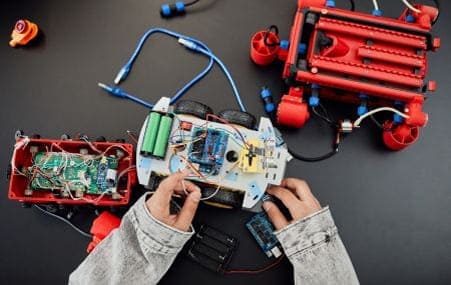

Cutting-Edge Prototyping Technology

GID leverages the latest technologies and tools in design and development, ensuring your product is innovative and competitive in the market.

Customized Product Development Solutions

Receive tailored solutions that meet your specific needs and requirements, ensuring the final product aligns perfectly with your vision and goals.

Rapid Prototyping Services

Accelerate your development timeline with rapid prototyping capabilities, allowing for quick iterations and improvements throughout the process.

Quality Assurance

Enjoy peace of mind with rigorous quality assurance processes, ensuring your product meets the highest standards of performance and reliability.

Not Sure Where To Start?

Call JIM

Expert Product Development Services:

From Start-ups to Enterprise Customers at GID Company

At GID Company, we specialize in providing expert product development services tailored to the unique needs of both start-ups and enterprise customers. Our goal is to transform visionary ideas into successful, market-ready products across various industries, ensuring that each client receives personalized support and solutions, no matter their size.

Customized Solutions for Every Business Stage

For start-ups, we offer agile and innovative product development solutions that help turn nascent ideas into viable products quickly and cost-effectively. We understand the dynamic nature of start-ups and provide flexible services that adapt to rapid changes and evolving market demands. Our team works closely with entrepreneurs to validate concepts, refine designs, and accelerate the path to market with strategic guidance and prototyping expertise.

For enterprise customers, we deliver comprehensive product development services that support large-scale and complex projects. Our approach for enterprises focuses on integrating new product developments seamlessly into existing product lines or systems while maintaining consistency and quality across all platforms. We leverage our extensive resources and deep industry knowledge to manage and execute large projects, ensuring they meet strict regulatory standards and corporate objectives.

Leveraging Advanced Technology and Expertise

We utilize state-of-the-art technology and methodologies to ensure superior design, prototyping, and manufacturing processes. Our team of experienced engineers and designers employs the latest in CAD software, 3D printing, and simulation tools to create precise and efficient product designs that cater to both start-ups and established enterprises.

Comprehensive Support from Ideation to Market Launch

Our service doesn’t stop at product development; we provide end-to-end support from the initial ideation phase through to market launch and beyond. This includes navigating regulatory approvals, scaling production, and even assisting with marketing strategies. We aim to be a long-term partner in our clients’ success, offering ongoing support to adapt products to new technologies and market changes.

A Commitment to Innovation and Excellence

At GID Company, we are dedicated to fostering innovation and delivering products that not only meet but exceed the expectations of our clients. We commit to high-quality outcomes, with a focus on enhancing functionality and user experience, ensuring that every product we develop sets a benchmark in its respective market.

Choose GID Company as your trusted partner in product development, where we help both start-ups and enterprise customers achieve their visions with our expert, tailored services. Let us take your product from concept to reality with the precision, innovation, and care it deserves.

Frequently Asked Questions - FAQs

-

What are product development services?

Product Development Services encompass the entire process of bringing a new product to market, from initial concept and design to prototyping, testing, and manufacturing. At GID Company, we offer comprehensive services to help businesses transform ideas into market-ready products, leveraging our expertise in engineering, design, and innovation.

-

What are the 4 major types of product development?

The four major types of product development include:

- New Product Lines

- Product Improvements

- Product Line Extensions

- New-to-the-World Products

GID Company’s Product Development Services are tailored to each type, ensuring a customized approach to meet your specific product goals.

-

How much do product development services cost?

The cost of Product Development Services varies depending on the complexity of the project, design requirements, prototyping needs, and market readiness. GID Company offers flexible pricing to accommodate different budgets, providing high-quality solutions without compromising on innovation or performance.

-

What industries does GID Company serve?

We cater to a diverse range of industries, including consumer electronics, medical devices, industrial equipment, and consumer goods. Our expertise allows us to adapt our services to meet the unique needs of each sector.

-

What are the 7 types of product development?

The 7 types of product development include:

- New Product Development

- Product Modification

- Product Enhancement

- Market Expansion

- Repositioning of Existing Products

- Diversification

- Product Line Expansion

GID Company provides expert Product Development Services in all these areas, ensuring that your product is competitive and well-positioned in the market.

-

What are examples of product services?

Examples of Product Development Services include product design, prototyping, material sourcing, manufacturing process development, and testing. GID Company’s services cover each of these aspects, ensuring that every stage of your product’s journey is handled with precision and expertise.

-

What are the 5 stages of product development?

The 5 stages of product development are:

- Idea Generation

- Concept Development

- Prototyping

- Testing and Validation

- Commercialization

At GID Company, our Product Development Services guide you through each of these stages, from concept to market launch, ensuring that your product is successful and meets all industry standards.

-

How does GID Company ensure the confidentiality of my product ideas?

We take intellectual property protection seriously. We have strict confidentiality agreements in place to safeguard your ideas and information throughout the development process.

-

What sets GID Company apart from other product development firms?

We pride ourselves on our collaborative approach, commitment to innovation, and focus on delivering tangible results. Our experienced team combines technical expertise with creative thinking to bring your product vision to life, exceeding your expectations and driving your business success.