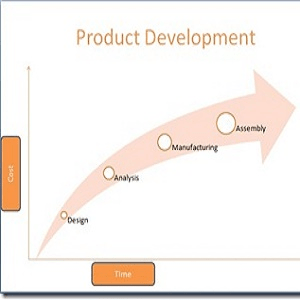

Every business around the globe operates to earn the profit by selling their products or services. The quality of product or service offered by them is directly proportional to their success. Thus, companies undertake extensive research and development work when they introduce any new offering in the market. Most entrepreneurs engage in research and development for a new product that they want to introduce to the market. However, product idea and product design are the most important aspects of new product development.

Product ideas can be worth their weight in gold, but unless you have the potential to transform that idea into a fully functional product, it is nothing more than just an idea. Being a product design and manufacturing company, we understand that not every business owner is technically sound and possess the ability to create a functional product on their own. Therefore, instead of getting stuck somewhere in the middle of the manufacturing process, it is advisable to hire a product design company to do the job professionally.

Hiring an external product design company is extremely beneficial, but if you still want to do the job by your own, then follow these steps to bring a product idea to life.

Step 1 – Product Idea

This step comprises of basic drawing revolving your product idea. Therefore, always ask yourself – what would be your product, for whom you are developing a product, what would be the features of your product, and how to make it user-friendly?

Step 2 – In-depth Research

Even though you might have a unique product idea, but make a research about whether your targeted market is ready for it or not. It is necessary to study the existing market trends and requirements. Therefore, you need to conclude what is currently ruling in the market and is there anything identical to your product concept. If you find something identical, then how is your product going to be better?

Step 3 – Product Design and Development

Make the use of information that you have collected from your survey/study. Based on the collected information, start creating product designs. But wait, when you are outlining the design of your product, you need to ask yourself the following questions:

- What is the job of my product?

- Will the product be reliable?

- Will my product be able to survive the rough use?

- Can the product be manufactured at a cost effective price?

- What will be the quality of my product?

- What raw material is best for development?

Step 4 – Research and Development of the Final Design

This is the final step to your product designing with dimensions and raw-material selection; therefore, before you move on to prototyping stage or manufacturing phase, make sure you have a complete sketch to work from.

Also, Read our latest posts:

GID Company Offers Best Product Design in California

Need Product Prototype Development? Visit GID Company

Why Choose GID – A Leading Product Development Company?

Step 5 – CAD

With the help of 3D modelling software (CAD – Computer Aided Design), you will develop a computerized 3D model of your absolute product design. These 3D models will often show up problematic areas where the theoretical stresses and strains on the product to be developed will be exposed. If any problem persists, it is a best phase of product development to handle the design errors and go back to step 4.

Step 6 – Prototype Development

Once you get the green signal from the previous step, it is the time to create a fully functional prototype of your product design using computer aided engineering systems. A physical model of your design is the best option for testing product features.

Step 7 – Prototype Testing and Feedback

Test your product prototype with family, friends, and potential financiers. You must be fair with your decisions while testing the prototype and listen to the feedback you get back from other people. Check, whether every part is functioning properly or not. If your prototype is not perfect, then move back to 3rd step and start on your product designs.

Step 8 – Product Manufacturing

Once you are satisfied with the performance of your product prototype, you can proceed to the manufacturing stage. Product manufacturing expenses entirely depend on the density of your product, especially, if there are numerous parts, material selection, high batch product or low batch numbers. Being a smart business owner, you need to consider these factors to make sure you manufacture a healthy product for handsome profit.

Follow these steps to take your product idea to manufacturing. Engineering plays a crucial role in custom product development, but marketing, sales, and manufacturing are crucial, too. A successful new product comes from the harmonic combination of insights from all areas.

To know more about product design and development service in California, please visit: www.gidcompany.com