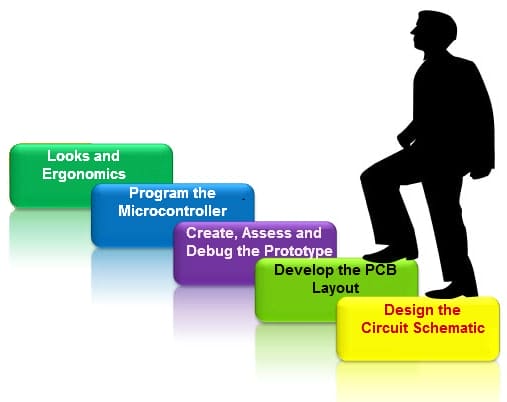

Development of products with electronics is as equally challenging as the development of generic, non-electronic products. New product development, whether electrical, mechanical, electromechanical, medical, or generic, is a tough task. Materializing a mere new product concept into reality involves several steps. For products with electronics, however, in addition to the standard product development steps, there are several more steps involved. Here in this blog, we shed some light on 5 important steps that entail the development of new products with electronics.

Step 1. Design the Circuit Schematic

Designing the circuit schematic for products with electronics usually involves early research so as to identify and select the ideal topology (circuit diagram) and most affordable, yet efficient components.

The step may also include running software simulations as well as bread boarding. Speaking of bread boarding, it is nothing but the creation of basic prototypes for products with electronics.

Designing the circuit schematic requires lots of thinking and considerable years of experience in the field of electronics engineering. In order to design the circuit schematic for new products with electronics, industry experts use some sort of computer software application. There are many such software applications available, but SOLIDWORKS, a part of the 3DEXPERIENCE platform from Dassault Systèmes, is the most versatile and popular.

Step 2. Develop the PCB (Printed Circuit Board) Layout

Utilizing the same software application as in Step 1., the experts now develop the PCB layout for the new product with electronics.

While some portion of the PCB layout may be auto-routed, the remaining portion would normally be routed manually. Usually, the PCB layout is very sensitive, for power components as well as RF components, such as Wi-Fi, Bluetooth, GPS, etc.

Once the final layout is ready, the software application will let the expert know, whether the PCB matches with its schematic. The software will also check wire lengths, wire widths, spacing, and so on, to ensure that the PCB layout meets all the guidelines for the specific PCB fabrication process being used.

Step 3. Create, Assess and Debug the Prototype

Based the circuit schematic and PCB layout, a prototype PCB of a new product with electronics is fabricated and assembled with all the right electronic components. With the prototype ready, it is thoroughly assessed, and if any issues or problems are found, it will be noted and rectified.

Most inventors expect to go everything right on the first try, but this is not possible. No product prototype, whether for generic, electronic, or mechanical product, is perfect or flawless on the first go. There are always some issues with the first prototype, which need to be rectified. Rectifying a prototype PCB is a difficult step because identifying the precise problem in the field of electronics is not something easy. Even after the precise identification of the problem, coming up with a right fix can take some time.

Step 4. Program the Microcontroller

Today, almost all products with electronics have some sort of microcontroller, a small computer in the form of a chip, which acts as the brain of the product.

These microcontrollers are programmable, and they are often programmed using “C” programming language. If the program needs to be fast and efficient, other high-level assembly languages may be used.

Often, the microcontroller is programmed by the expert who has designed the circuit; however, sometimes a specialist is brought to do the programming.

One a side note, because the products with electronics use a programmable microcontroller, they can also be called products with imbedded software.

Step 5. Looks and Ergonomics

This step is always handled by other professionals. An expert who is proficient in 3D modeling is needed to create the adequate looks and ergonomic (user-friendly, comfortable and functional) designs for the new products with electronics.

Creating the packaging, i.e. the outer body or casing, for the products with electronics is a challenging task. Electrical products are susceptible to various damages; thus, when designing and developing the packaging for the products with electronics, the experts need to consider the following factors:

- Protection from electrostatic discharge

- Protection from mechanical damage

- Protection from electromagnetic interference

- Protection from heat

- Ease of maintenance

- Cost

As mentioned before, the development of products with electronics is challenging. Therefore, it will be a great idea to hire an eminent product design and product development company that, along with the design and development of generic products, also specializes in the design and development of products with electronics.

If you happen to be an innovator and need help in the design and development of the new products with electronics, then GID Development Corporation is here to help. A leading product design and product development company in California, USA, GID Development Corporation specializes in the design and development of products with electronics, electromechanical products, medical device products, and other generic as well as special-purpose products. They use the 3DEXPERIENCE platform from Dassault Systèmes, which assists them in designing and developing accurate product prototypes at reduced cost and time. No matter what the new product concept is, GID Development Corporation can “Get It Done.”

To learn more about GID Development Corporation, just visit https://www.gidcompany.com/.

Currently, GID Development Corporation is offering a free 15-minute telephonic consultation with one of the veterans, Jim Grimes. You can call Jim Grimes at 714-323-1052 between 8:00 AM to 5:00 PM PST.