Being one of the most reputed and experienced product design companies in California, USA, we leave no stone unturned when it comes to customer satisfaction. In our course of two decades of industry experience, we have served companies of all sizes in all industries, delivering the most up-to-date solutions. As customer satisfaction is always at the top of our list, we never compromise with the quality of products that are developed under the banner of GID.

With the intention to continue the same series of customer satisfaction and flawless product design solutions; we have upgraded ourselves to the most advanced version of CATIA Software .i.e. CATIA V6. The CATIA V6 is the latest version of CATIA software that is designed to go far beyond the traditional CAD / CAM / CAE software tools to provide a unique Digital Product Experience. We are better enabled with the inclusion CATIA V6 software and pledge to leverage the capacity of innovation for clients by delivering breakthrough design solutions powered by the 3D Experience platform. To know more about CATIA software, please visit https://www.gidcompany.com/tag/catia/

Introduction to CATIA V6

Developed by a French company Dassault Systèmes in 1977, CATIA (Computer Aided Three-Dimensional Interactive Application) software was primarily developed to propel Dassault’s in-house Mirage Fighter Jet project. However, due to its overwhelming features, it was gradually adopted by different industries, including automotive, aerospace, electrical, plant design, electronics, etc. Furthermore, enchanted by its runaway success, thousands of companies across the globe, including Boeing and IBM also began using CATIA to design different products and parts.

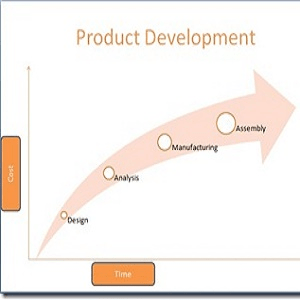

CATIA V6 is the latest addition to the CATIA family with tons of features to leverage the capacity of innovation for small, medium and large sized businesses. Stated as the most powerful and advanced product design software in the current market, CATIA V6 offers a lifelike experience, allowing everyone to visualize and experiment with the product throughout its development. It has the potential to put 3D collaborative innovation at the heart of the enterprise and aids to accelerate a companies’ transformation towards a full PLM (Product Life Cycle) 2.0 approach. Today, OEMs and thousands of other companies have adopted CATIA V6 to boost their business process.

Experience the Power of CATIA V6 at GID

At GID, we have upgraded ourselves from CATIA V5 to CATIA V6 for the advantage of our clients by providing amazing virtual design capabilities. The CATIA V6 allows our product designers and product engineers to offer a unique digital product experience that brings 3D product design to life with unmatched realism. We are now capable of offering product design solutions to clients of all sizes that are superior and far beyond the traditional CAD software tools.

- Use of CATIA V6 for System Engineering – Managing multiple modeling (mockups) and simulation applications at a time and meeting the delivery deadlines was never easy until the arrival of CATIA V6. The latter allows product designers at GID to deliver an exclusive solution that completely enables and supports the cross-discipline systems engineering development process from modeling to simulation, verification and management. With a unified and integrated approach towards system engineering, we are confident of delivering smart solutions for industries such as automobiles, industrial equipment, airplanes, and other complex electro-mechanical devices.

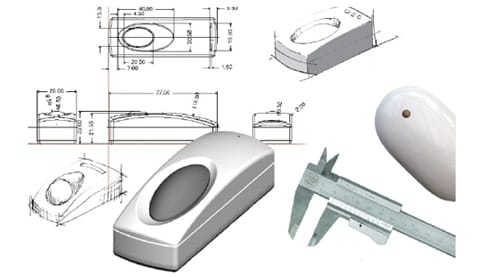

- Use of CATIA for Mechanical Design and Engineering – Need of multi-tasking products has increased the complexity in products. Integrating multiple features in a single product and at the same time maintaining the performance and quality has become challenging for product companies. However, CATIA V6 has made it an easygoing process by offering an early insight into the quality and performance of the product. It allows rapid manufacturing of high-quality mechanical products.

- Use of CATIA for Product Design – From aircrafts to shipbuilding and from automotive to electronics, product design plays an important role in determining a product’s success in the market. With the use CATIA V6, the product manufacturing company can quickly deliver aesthetically pleasing and functionally superior products. CATIA V6 covers all product design requirements, including design to Class A, offering product designers with the tools to design any kind of difficult shapes.

- Use of CATIA V6 for Electrical and Fluid Systems Design – The CATIA V6 has made it easy to manage the rising complexity of piping / tubing development process. CATIA V6 Fluid Design Solution offers a full and unified description of the fluid system for all industries, integrating company expertise and managing standards and specifications’ regulations. It streamlines the global collaboration to reduce design and development time.

CATIA V6 is a multipurpose, intuitive and easy to use software that allows everyone involved in the project a real time freedom to design any kind of complex shape. It covers all the aspects of product design requirements from simple to complex, enhancing abilities to create any kind of product design in the real time.

To know more about CATIA V6, or to schedule a free consultation to discuss your new product idea, feel free to contact product development company, GID at www.gidcompany.com. For free expert advice, give us a call at 714-323-1052.