Most inventors of a new product are often so enthusiastic about their latest product that they immediately proceed for a quick production and launch. This strategy, however, is not the right strategy, and it will probably end up in a failure.

You might be wondering, what is wrong getting the new product idea into gear straightaway. You have done the market research and have the right data; you know that there is an excellent market for your innovative product; then why shouldn’t you quickly get your new product to the market and start maximizing your profit? Well, there is a simple and logical reason for not doing this. You do not know yet whether your new product actually works or not. You still do not know whether you can mass manufacture that product efficiently and cost-effectively. Besides, despite knowing that there is an excellent market (based on your market research), you still do not know whether your target consumers will accept the new product. Therefore, the best way to know that your product works and will be embraced by the consumers is to create and test a prototype first.

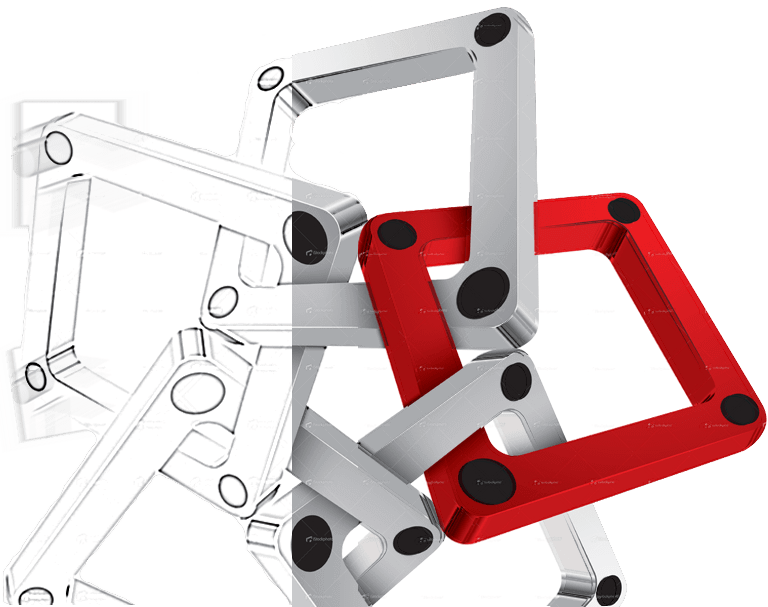

A product prototype development will take your amazing idea to the papers (you can formally call it blueprints) and then turn it into a real-life working model. A prototype is, in fact, a real working version of your well-thought-out product that functions or does everything the way you want it to do.

An eminent product prototype development company will develop a prototype using precise specifications as if the product was in production; however, they will not mass manufacture it yet, but will produce only a single item. One fundamental aspect of a working prototype is that it has to be designed and developed in such a manner that it represents the product, which can be mass produced before the launch, at an economical price.

It all depends upon the type of new product idea you have in mind. Let us have an overview of each of the product prototype types.

Mechanical Prototype

A mechanical prototype is one, which we can define as physically made from some material and has some mechanics involved. All the materials used for this type of prototype have to be real materials and the mechanics used should be as per the specifications. These materials and mechanics will later become part of the product ready for the mass production. This type of prototype will help refine the product design and mechanics, and at the same time, help judge the performance of the materials you plan to use.

Software Prototype

A software prototype is one, which does not have any physical characteristics, such as online transaction systems or a simple product, like a website. Creating a prototype software normally involves two stages – developing an “alpha” version and a “beta” version. In the alpha version, the development company will gradually develop various software features. Once they develop the necessary features, they will change that alpha version to a beta version. In the beta version, the development company will perform various tests and adjust the software as per the desired results. Beta versions are often distributed to users in order to get some valuable feedback. Based on the feedback, creating an excellent final software product is possible.

Electronics Prototype

Electronics prototype is one, which involves constructing an electrical circuit using a stripboard, breadboard, and various other electrical components. Based on the theoretical design, a prototype development company will build an actual circuit in order to verify whether the circuit can perform the desired functions or not. To a theoretical electronics design, this type of prototype is a physical platform where debugging is possible in order to achieve the desired results.

Product prototype development is essential for three major reasons:

-

A prototype serves as a basis for the actual product, which you can introduce in the market with maximum confidence and minimum risk. Besides, once you have a working prototype, you will now at least know that it is possible or viable to manufacture the actual product.

-

A prototype is a real, feasible thing that can easily excite the investors. With a product prototype and the data from your market research, you can create an excellent business plan that will show the potential of your product in the market to the investors.

-

A prototype is a working model of your idea that you can use as a basis for various marketing tests. With the working model, you will be able to conduct primary marketing research, which will indeed help you hone your approach to the market.