Most businesses using or dealing in plastic products or parts may not be manufacturing plastic products of their own. They hire a plastic product manufacturer to design and manufacture a plastic product or part as per their business requirements. Only in the United States of America, there are hundreds of thousands of custom plastic product manufacturing company; however, very few possess industry experience, talented professionals, and most importantly, advanced product design and manufacturing tools as the GID Development Corporation possesses.

Based in the heart of California, USA, GID is a custom plastic product manufacturer with more than forty years of industry experience; hence, it is comprehensively aware of every in and out related to plastic industry. At GID, we understand the importance of new development, and passionately endeavor to create a product that can make our clients rich and famous in their respective industry. Here are some more reasons to justify why the GID Development Corporation is the best plastic product manufacturing company for your business, and they are as follows:

- We are USA Based – The GID Development Corporation is a plastic product manufacturer based in California, USA, and this can benefit entrepreneurs in a number of ways. Reduced product manufacturing time is the first advantage that you gain from us by hiring our quality-oriented manufacturing services. As we are based in the United States, reduced shipping charge is yet another advantage that you enjoy by hiring our services. Moreover, same time zone permits us to work with you whenever you need us.

- 40+ Years of Industry Experience – More than 40 years of industry experience makes us stand above the beginners in the industry. Our industry experience helps us make rewarding decisions on behalf of our customers. We advise our clients in deciding on the most suitable raw material as well as help them in finalizing advantageous manufacturing procedures to develop the most rewarding new plastic product.

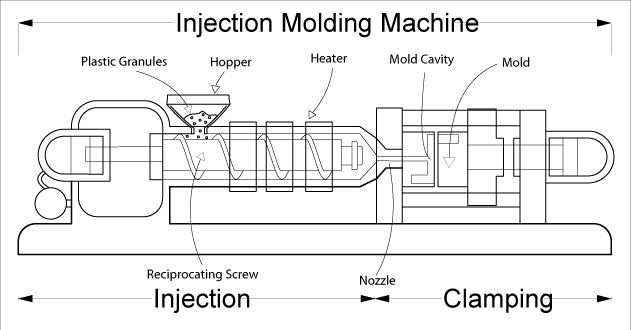

- Expertise in Different Plastic Product Manufacturing Methods – As an entrepreneur, whether you want to develop a new product using extrusion method, rotational molding method, injection molding method or any other method, we possess expertise in all the major manufacturing techniques. Furthermore, we also suggest the most suitable product manufacturing methods depending upon the type of raw materials and end-product requirements. We are capable of handling different manufacturing processes effectively.

- Quality Product Design and Manufacturing Services Using Advanced Tools – We strive for perfection in everything we do; hence, we use the most advanced tools, including CATIA V6, for product design and development. Along with professional product design and manufacturing services using the most advanced tools available in the industry, we offer additional services to our clients, such as testing concept feasibility, developing a product prototype, analyzing competitors’ products and more. Additionally, we also offer assembly services to entrepreneurs who would love to have finished products at once.

- Experience of Working with Different Business Entities – Hiring the GID Development Corporation for plastic product manufacturing brings countless returns. We have experience of serving different business entities, including the marine, electronics, consumer durable, aerospace, automotive, and healthcare to name a few. Being a plastic product manufacturer with four decades of experience, we are capable of catering to a number of these industries.

With a teams of highly qualified and experienced designers, engineers, product analysts, and project managers, we provide a full range of commercially led manufacturing services, such as industrial product design, product development, and product prototype development. We offer quality plastic product manufacturing services that ensure long-term success for our clients. You can contact us at www.gidcompany.com to find out how we could help you.