Someday, early in the morning you had your eureka moment. You know that the new product idea that just evoked your mind is worth development and will generate a huge profit for you. However, you don’t have a skilled workforce, adequate experience to initiate the project nor you have industry certified tools to embark the project. So, should you drop the idea of developing a revolutionary product? Absolutely not. Go for choosing a Custom Product Manufacturer in the United States.

In the age of globalization, there are thousands of product manufacturing companies keen to help with custom product development. Here’s how to choose the right custom product manufacturer to get the job done in the most professional and efficient manner.

What to Look for When Hiring a Custom Product Manufacturer

- Hire a company whose primary business is product development

- Hire a company having a collection of technical and experienced professionals

- Hire a company familiar with the latest technologies

- Hire a company having its root deeply penetrated in the marketplace

- Hire a company having a team to offer a fresh point of view

- Hire a company having dedicated resources to bring significant specialized experience to any project

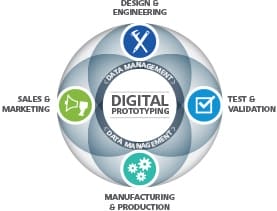

- Hire a company that knows and offers the right combination of services

According to an ancient quote, “If the only tool you have is a hammer, you will see every problem as a nail”. Therefore, find a full-service provider who fits your project requirements, and not one having limited resources and limited industry experience. You should strictly follow this quote while finding a product manufacturing company because, in the 21st century, injection molders, rapid prototypers (SLA service bureaus), board houses, and even plastic suppliers describe themselves as custom product manufacturers. As a responsible entrepreneur, you need to ensure that the product development company you hire is not limited to solutions based on their core business.

Contact the GID Development Corporation

For startups, small, and medium-sized businesses who want to establish their unique presence in the market, we help them with everything they are searching for. Hiring GID as a custom product development will allow you to take advantage of opportunities, which are not part of your core business and develop products that are not simply extensions of their existing product lines. At GID, we have dedicated resources to professionally execute all of the design and engineering jobs.

The GID Development Corporation is not an ordinary manufacturer, a molding shop, or a circuit board house. If you need the services of skilled product developers, we have the resources, the tools, and the experience to bring your ideas into reality.